Spraying device for inner wall of pipe body

A spraying device, a technology inside a pipe, applied in spraying devices, devices for coating liquid on surfaces, coatings, etc., can solve problems such as unfavorable human health, poor spraying effect, high labor intensity, etc., achieve simple structure, improve production Efficiency, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings of the description.

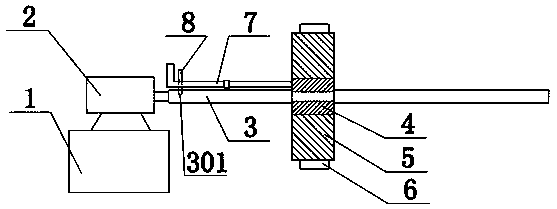

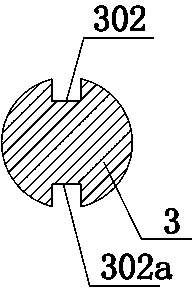

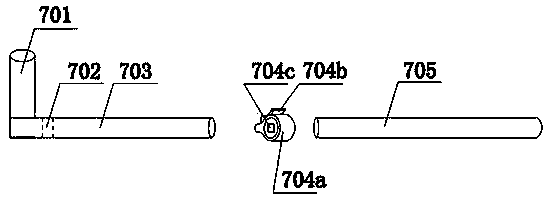

[0014] As shown in the figure, the spraying device for the inner wall of the pipe includes a base 1, a motor 2 is installed on the base 1, the output shaft of the motor 2 is connected to a rotating shaft 3, and two sliding slots A302, A302, Slider ring 4 is arranged on chute B302a, chute A302, and chute B302a to slide in its axial direction. The outer part of slider ring 4 is provided with turntable 5 fixedly connected with it. On turntable 5, 1-3 spouts are evenly distributed outwards. The spray gun 6 is also fixedly connected to the telescopic push-pull rod 7 on the slider ring 4. A limit groove 301 is set on the rotating shaft 3, and a limit hole 702 is correspondingly set on the telescopic push-pull rod 7. The locking pin 8 passes through the limit hole 702 and the limit groove 301 to lock and position the telescopic push-pull rod 7 and the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com