Magnet back adhesive tape bonding machine

A gluing machine and magnet technology, which is applied in the field of adhesive magnet processing equipment, can solve the problems of easy sticking to the wrong position, low work efficiency, and decreased viscosity, and achieve the effects of avoiding pollution, high degree of automation, and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

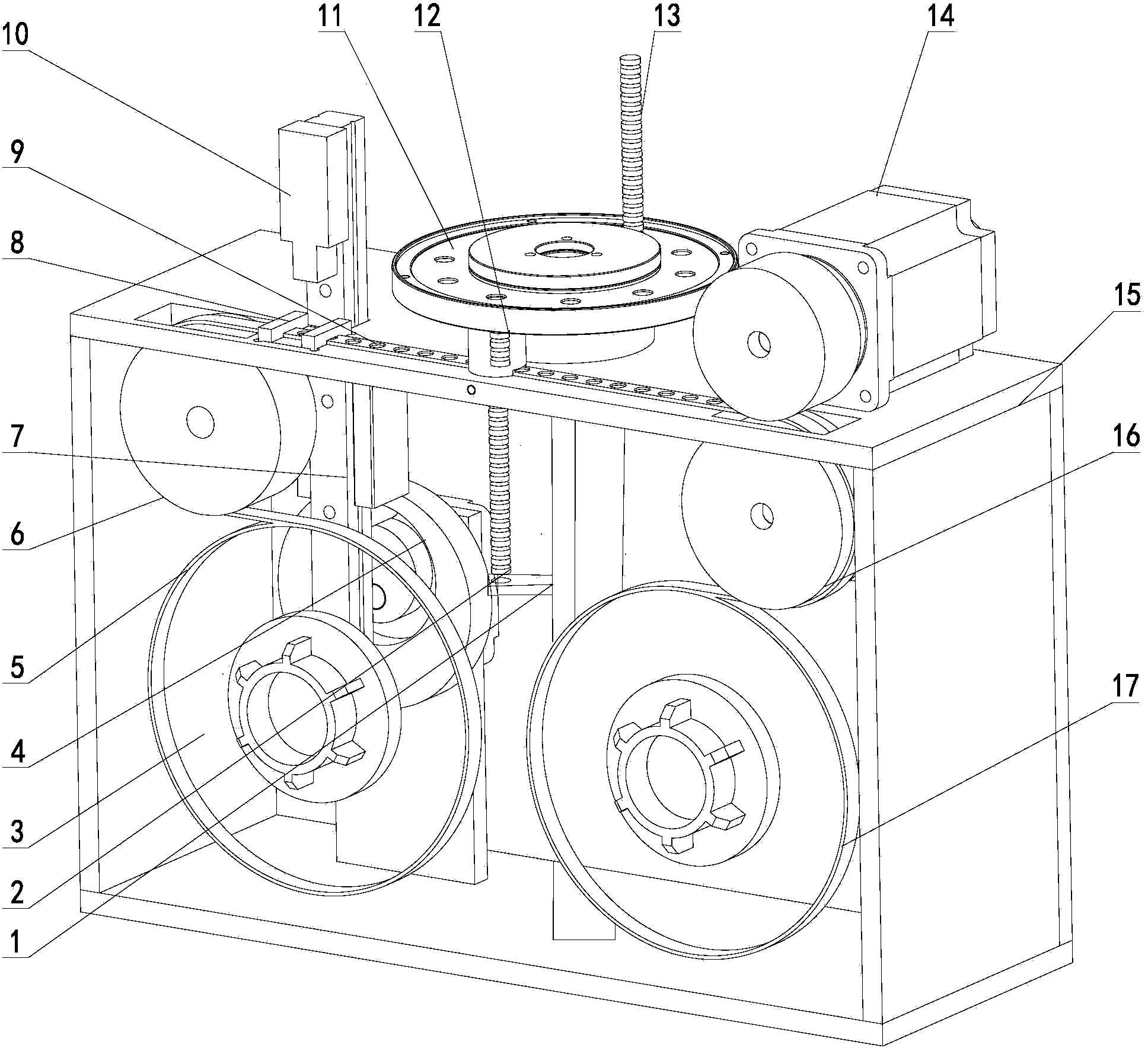

[0009] Such as figure 1 As shown, the magnet back adhesive applicator of the present invention comprises a base 15, a distribution tray 11 fixed on the top of the base 15 for magnet distribution, and fixed on the base 15 for storing adhesive tape 5 The adhesive tape installation plate 3, the belt release guide wheel 6 used for tape pushing and guiding, the tape punching device and tape traction device fixed on the top of the base 15; the distribution plate 11 is provided with a plurality of distribution holes, so The upper part of the base 15 is provided with a blanking hole 12 docked with the distribution hole and the tape punching sheet, and the bottom of the blanking hole 12 is provided with a lifting mechanism 1 for compressing and separating the magnet and the tape punching sheet; Including a drive device for driving the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com