Electrical control system of anode assembly casting vehicle and control method of electrical control system

An electrical control system, casting car technology, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of step-by-step speed regulation and inaccurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

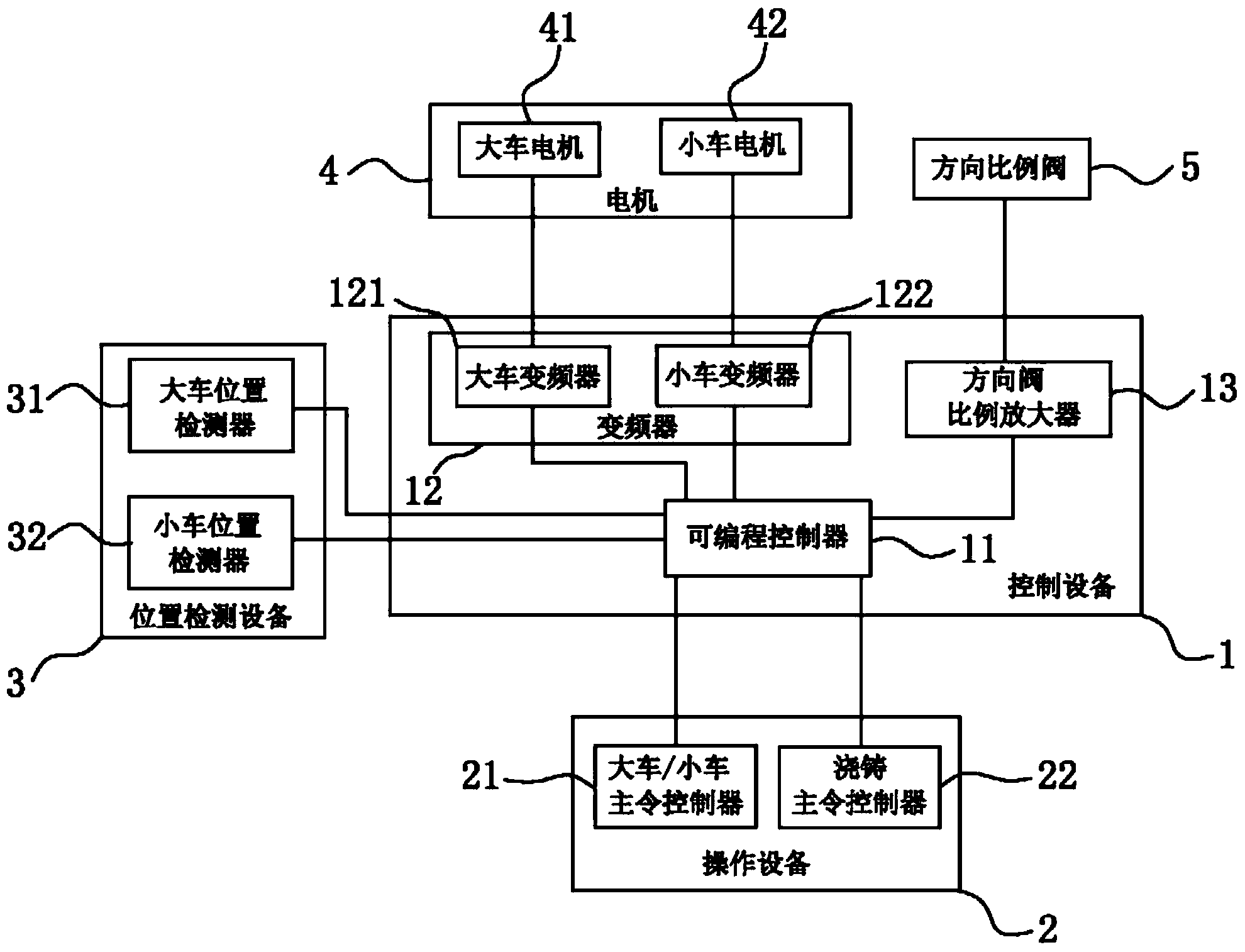

[0030] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the electrical control system and the control method of the anode assembly casting car proposed according to the present invention are specifically implemented below in conjunction with the accompanying drawings and preferred embodiments Ways, methods, steps, features and effects thereof are described in detail below.

[0031] The core of the present invention is that the owner of the cart / trolley instructs the controller to generate a switch signal and an analog signal, and the programmable controller separately processes the received switch signal and the analog signal and sends them to the The frequency converter is controlled by the programmable controller to drive the operation of the motor, the switch signal controls the start and stop of the motor, and the analog signal controls the continuous speed regulation and direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com