CO2-soluble foaming agent and its preparation method

A foam agent and foam technology, applied in the field of CO2-soluble foam agent and its preparation, can solve problems such as difficult injection and corrosion of wellbore, achieve good solubility and foam stability, and improve injectability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

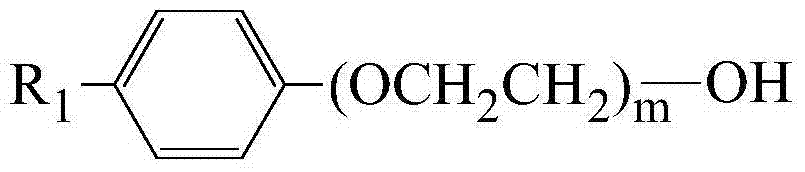

Method used

Image

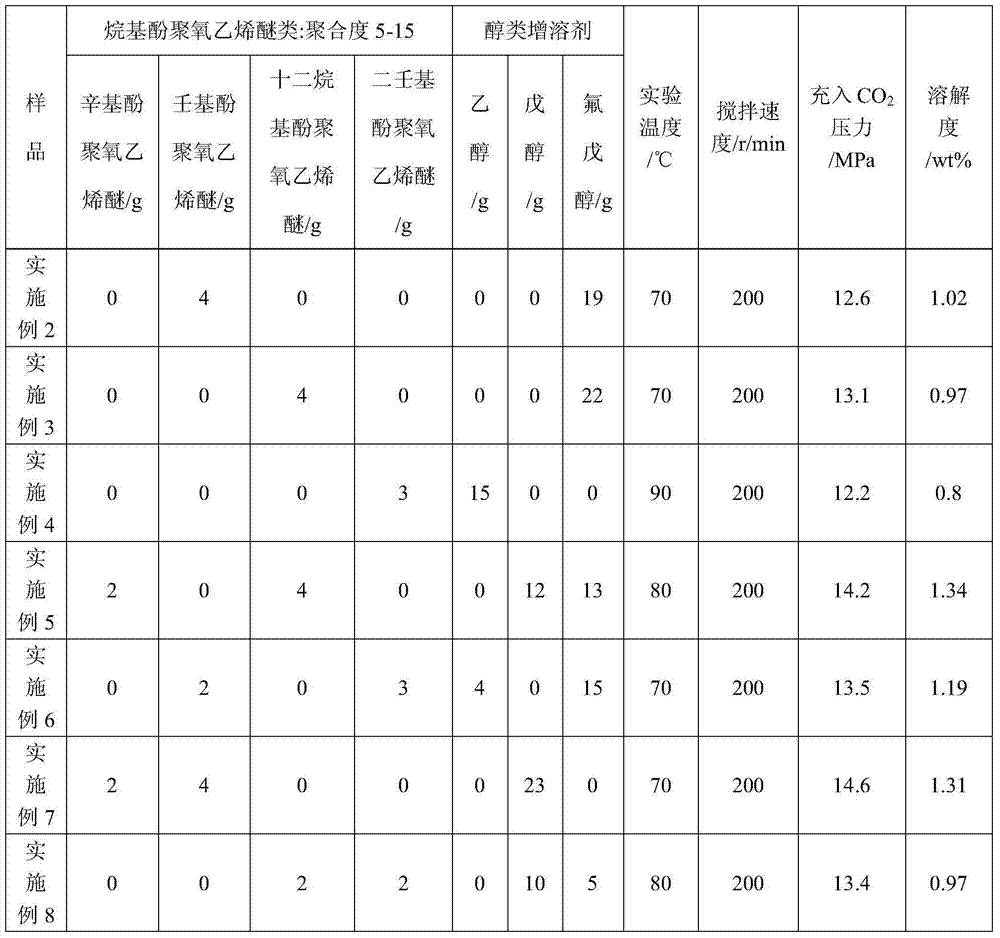

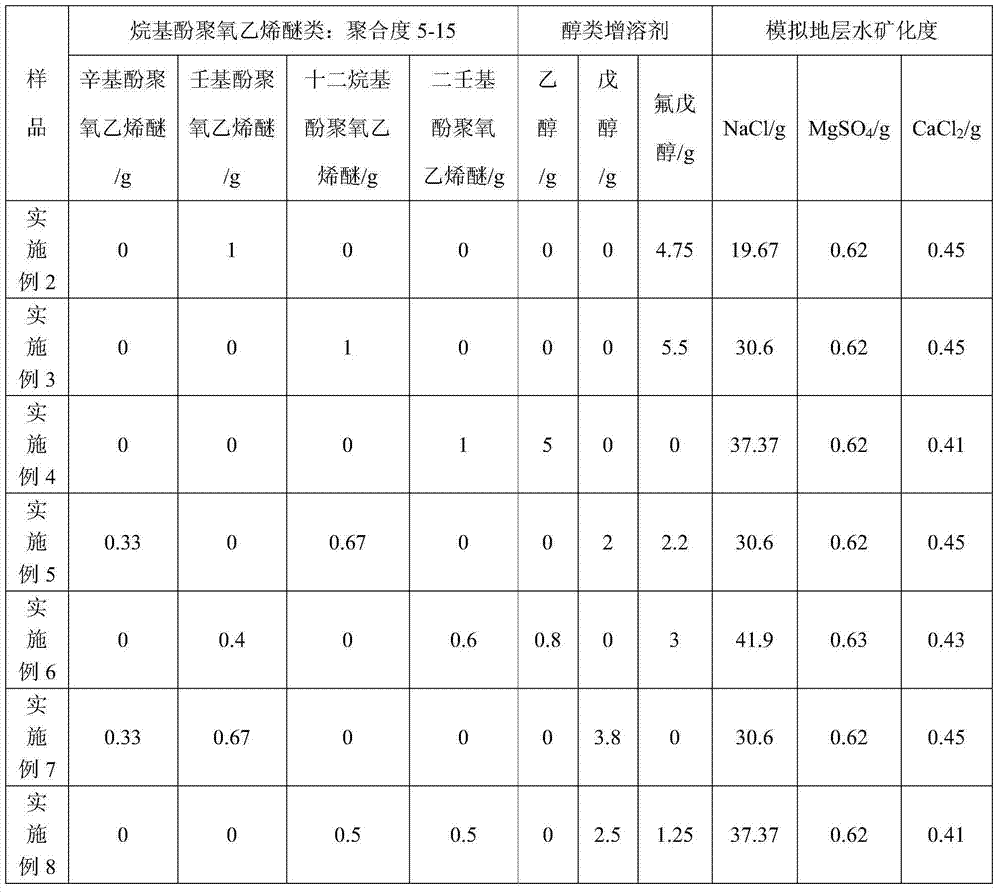

Examples

Embodiment 1

[0026] Mix 3g of octylphenol polyoxyethylene ether with a degree of polymerization of 5 to 15 and 12g of amyl alcohol and add it to a high-temperature and high-pressure visual foam instrument. Heat the foam instrument to 80°C, stir it evenly, and gradually fill it with CO 2 , and stirred at a speed of 200r / min until all octylphenol ethoxylates and amyl alcohol were dissolved in CO 2 , record that the pressure inside the foam instrument is 10.3MPa at this time, and calculate the added CO 2 The mass is 305.91g, so it is calculated that octylphenol polyoxyethylene ether in CO 2 The solubility in is 0.94%, which shows that the prepared foam has good solubility.

[0027] Prepared CO soluble 2 After the foaming agent is injected into the oil reservoir, it will generate foam when it encounters formation water to realize the plugging effect. With 30.6g NaCl, 0.62g MgSO 4 and 0.45g CaCl 2 Prepare 200ml of simulated high-salinity formation water with a salinity of 150,000mg / L; take...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com