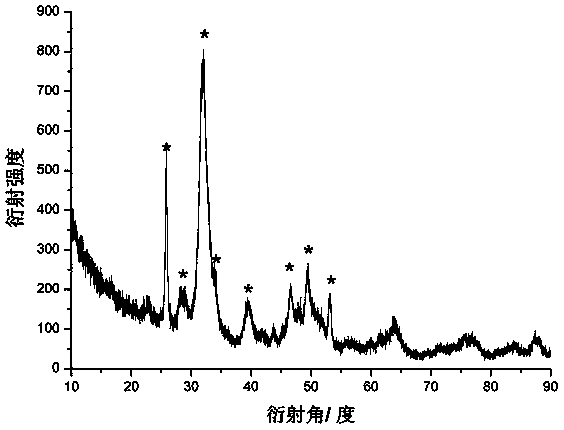

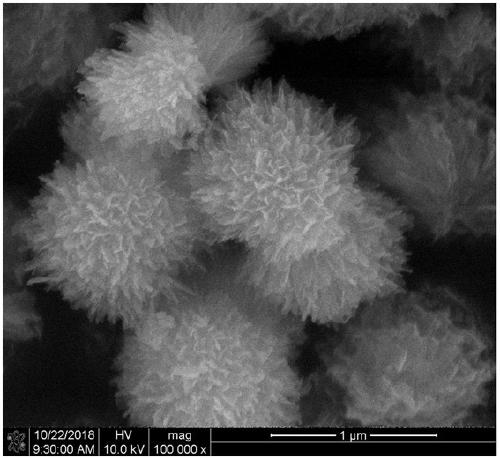

Preparation method of small-size abalone shell hydroxyapatite porous microspheres

A technology of shell hydroxyapatite and hydroxyapatite, which is applied in the field of preparation of small-sized abalone shell hydroxyapatite, can solve the problems of resource waste, environmental pollution, etc., achieve low cost, simple preparation method, and improve injectability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Soak the abalone shell in acetic acid solution with a volume fraction of 30% for 6 hours, remove the surface material, rinse it with deionized water, and let it dry naturally;

[0039] 2) Crushing and grinding the air-dried abalone shell, and screening with a 200-mesh filter to obtain abalone shell powder;

[0040] 3) Take 0.5g of abalone shell powder, dissolve it in acetic acid solution with a volume fraction of 10%, and centrifuge to obtain the supernatant after stirring continuously until no bubbles are generated. The centrifugation speed is 9000rpm, the time is 5min, and the temperature is 4°C;

[0041] 4) Dilute the supernatant to 50ml, transfer it to a 100ml beaker, and add phosphoric acid solution (50ml, 0.06M) dropwise at a rate of 1ml / min (guarantee that the Ca / P molar ratio is n(Ca 2+ ):n(PO 4 3- )=1.67:1), the whole process continued to stir.

[0042] 5) After the phosphoric acid solution is added dropwise, add 0.2352g sodium citrate, 1.25g polyaspartic...

Embodiment 2

[0047] 1) Soak the abalone shell in acetic acid solution with a volume fraction of 20% for 6 hours, remove the surface layer, rinse with deionized water, and let it dry naturally;

[0048] 2) Crushing and grinding the air-dried abalone shell, and screening with a 200-mesh filter to obtain abalone shell powder;

[0049] 3) Take 0.5g of abalone shell powder, dissolve it in acetic acid solution with a volume fraction of 20%, and centrifuge to obtain the supernatant after stirring continuously until no bubbles are generated. The centrifugation speed is 9000rpm, the time is 5min, and the temperature is 4°C;

[0050] 4) Dilute the supernatant to 50ml, transfer it to a 100ml beaker, and add phosphoric acid solution (50ml, 0.06M) dropwise at a rate of 1ml / min (guarantee that the Ca / P molar ratio is n(Ca 2+ ):n(PO 4 3- )=1.67:1), the whole process continued to stir.

[0051] 5) After the phosphoric acid solution is added dropwise, add 2.3528g of sodium citrate, 6g of polyaspartic ac...

Embodiment 3

[0056] 1) Soak the abalone shell in acetic acid solution with a volume fraction of 10% for 6 hours, remove the surface material, rinse it with deionized water, and let it dry naturally;

[0057] 2) Crushing and grinding the air-dried abalone shell, and screening with a 200-mesh filter to obtain abalone shell powder;

[0058] 3) Take 0.5g of abalone shell powder, dissolve it in acetic acid solution with a volume fraction of 10%, and centrifuge to obtain the supernatant after stirring continuously until no bubbles are generated. The centrifugation speed is 9000rpm, the time is 5min, and the temperature is 4°C;

[0059] 4) Dilute the supernatant to 50ml, transfer it to a 100ml beaker, and add phosphoric acid solution (50ml, 0.06M) dropwise at a rate of 1ml / min (guarantee that the Ca / P molar ratio is n(Ca 2+ ):n(PO 4 3- )=1.67:1), the whole process continued to stir.

[0060] 5) After the phosphoric acid solution is added dropwise, add 0.2352g sodium citrate, 5g polyaspartic ac...

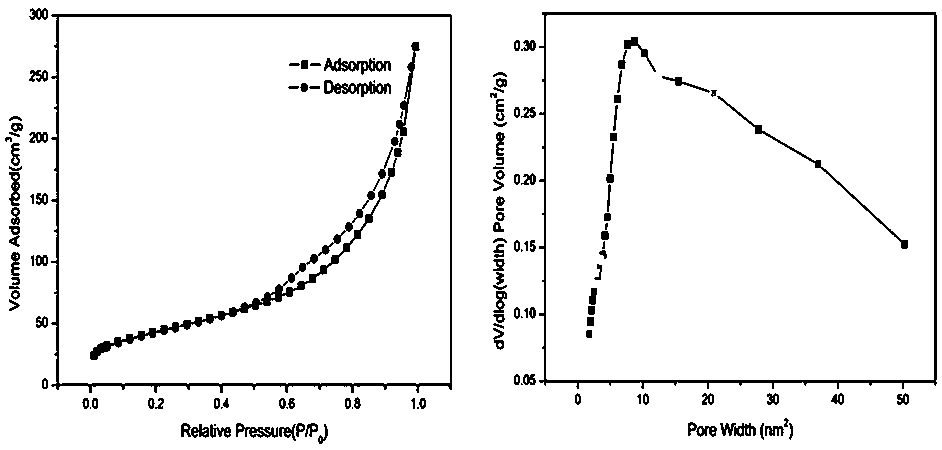

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com