Medical composite biological bone cement powder, bone cement liquid and composite biological bore cement

A bone cement and biological technology, which is applied in the field of medical composite bio-bone cement powder, bone cement liquid and medical composite bio-bone cement, can solve the problems of few researches on bone cement, poor injectability, difficult blood solidification, etc., to achieve Effects of improved injectability, increased fluidity, and increased compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Bone cement powder:

[0036] Synthesis of apatite: Feed calcium hydroxide and phosphoric acid at a calcium / phosphorus molar ratio of 1.60-1.67, and obtain apatite through the following reactions:

[0037] Dry the obtained apatite slurry at 120°C, grind it finely, pass through a 100-mesh sieve, and set aside.

[0038] Preparation of fine powder of polyamide components: Add polyamide 6 or polyamide 66 resin to the mixed solution of acetamide and calcium chloride (calcium chloride / acetamide ~ 20% g / ml), at 120°C-160°C Dissolve under heating conditions, cool to room temperature, pour into deionized water, very fine powder, centrifuge and wash 3 times, dry at 60-80°C, pass through a 100-mesh sieve, and set aside.

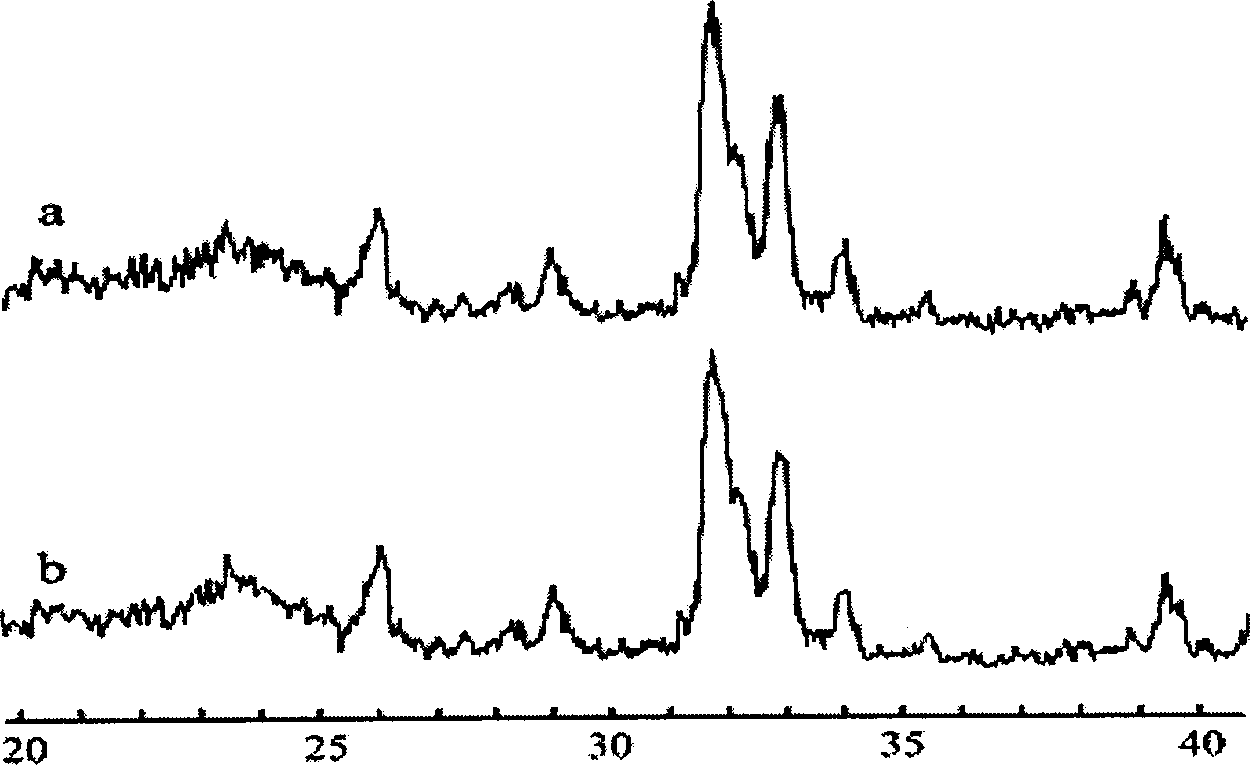

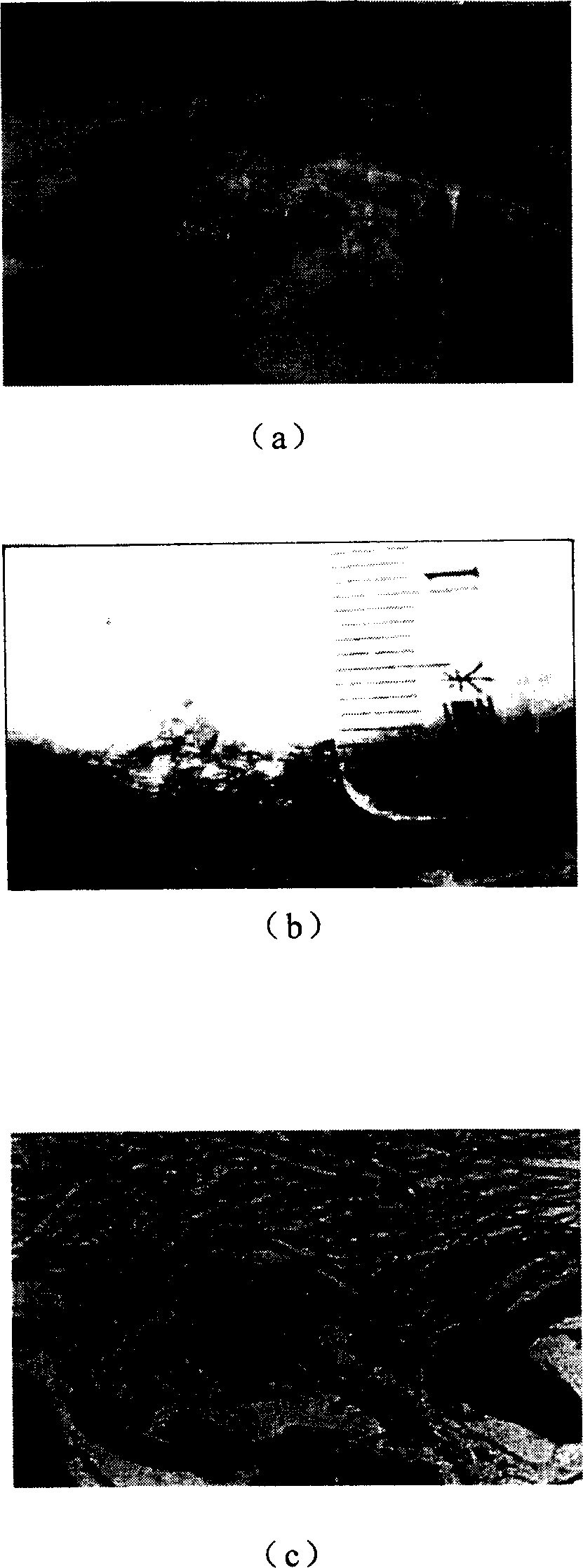

[0039] Preparation of bone cement fine powder: mix the above-mentioned apatite fine powder and polyamide 6 or polyamide 66 fine powder in a ratio of 1:1 by weight, grind to fine powder, wash twice with distilled water, dry again, and grind to fine powde...

Embodiment 2

[0045] Except for the ratio of 1:0.4 by weight when mixing the fine powder of apatite and the fine powder of polyamide 6 when preparing the fine powder of bone cement, the rest of the preparation methods and processes refer to Example 1. The apatite content in the injectable bone cement material obtained in this example can reach about 70%.

Embodiment 3~4

[0047] In Example 1 and Example 2, the mixing ratio of bone cement fine powder and bone cement liquid was changed to be lower than 1:1 when preparing bone cement, and the rest of the preparation methods and processes were referred to Example 1. Non-injectable bone cement materials with apatite content of about 50% and about 70% can be obtained respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com