Precious metal smelting smoke dust pretreatment method

A precious metal, pretreatment technology, applied in the direction of improving process efficiency, etc., can solve the problems of selenium element dispersion, unfavorable recovery of selenium, loss of precious metals, etc., achieve the effect of less impurity content, solve the recovery of valuable metals, and high grade of precious metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

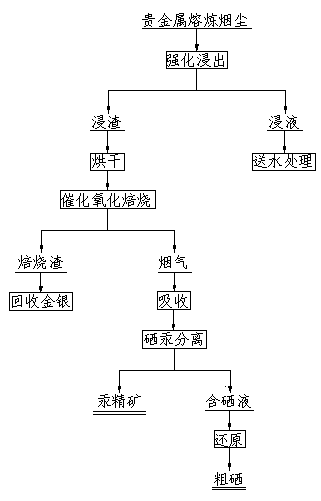

[0040] A precious metal smelting fume, its main components and contents are: Au 0.58%, Ag 5.9%, Se 5.32%, Hg 6.22%, C 2.14%, Na 9.11%, Zn 2.39%, Cl 46.6%, the total grade of precious metal is about 6.5% . The specific preprocessing steps are as follows:

[0041] 1) Add 1500mL of water into the acid-resistant reaction vessel with stirring, turn on the stirring, add sulfuric acid to adjust the pH value to 0.5, and add 500g of precious metal smelting dust, that is, the liquid-solid weight ratio is 3:1. After stirring evenly, add 2.65g of cosolvent zinc powder, 1.24g of sodium hypophosphite, and 1.11g of sodium pyrosulfite.

[0042] 2) Control the temperature at 70°C for enhanced leaching for 1.5 hours. After the leaching is completed, the solid and liquid are separated to obtain leaching residue and immersion liquid. The leaching residue is roasted by catalytic oxidation, and the immersion liquid is sent to water treatment.

[0043] 3) Drain the slag and dry it, add the catalys...

Embodiment 2

[0047] A precious metal smelting dust, its main components and contents are: Au 0.21%, Ag 8.0%, Se 5.03%, Hg 5.98%, C 1.46%, Na 9.32%, Zn 4.51%, Cl 44.9%, the total grade of precious metal is about 8.2% . The specific preprocessing steps are as follows:

[0048]1) Add 1500mL of water into the acid-resistant reaction vessel with stirring, turn on the stirring, add hydrochloric acid to adjust the pH value to 1.5, and add 1500g of precious metal smelting dust, that is, the liquid-solid weight ratio is 1:1. After stirring evenly, add 7.96g of cosolvent zinc powder, 3.71g of sodium hypophosphite, and 3.33g of sodium pyrosulfite.

[0049] 2) Control the temperature at 95°C to carry out intensive leaching for 3.0 hours. After the leaching is completed, the solid and liquid are separated to obtain leaching residue and leaching liquid. The leaching residue is roasted by catalytic oxidation, and the leaching liquid is sent to water treatment.

[0050] 3) Drain the slag and dry, add t...

Embodiment 3

[0054] A precious metal smelting fume, its main components and contents are: Au 2.48%, Ag 2.1%, Se 9.96%, Hg 6.44%, C 3.70%, Na 8.16%, Zn 1.55%, Cl 44.1%, the total grade of precious metal is about 4.6% . The specific preprocessing steps are as follows:

[0055] 1) Add 2100mL of water into the acid-resistant reaction vessel with stirring, turn on the stirring, add sulfuric acid:hydrochloric acid at a ratio of 1:1 to adjust the pH value to 2.5, add 300g of precious metal smelting dust, that is, the liquid-solid weight ratio is 7:1. After stirring evenly, add 1.59g of cosolvent zinc powder, 0.74g of sodium hypophosphite, and 0.67g of sodium pyrosulfite.

[0056] 2) The temperature is controlled at 50°C for enhanced leaching, and the enhanced leaching lasts for 4.0 hours. After the leaching is completed, the solid and liquid are separated to obtain leaching residue and immersion liquid. The leaching residue is roasted by catalytic oxidation, and the immersion liquid is sent to w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com