Harmless treatment method of black copper mud

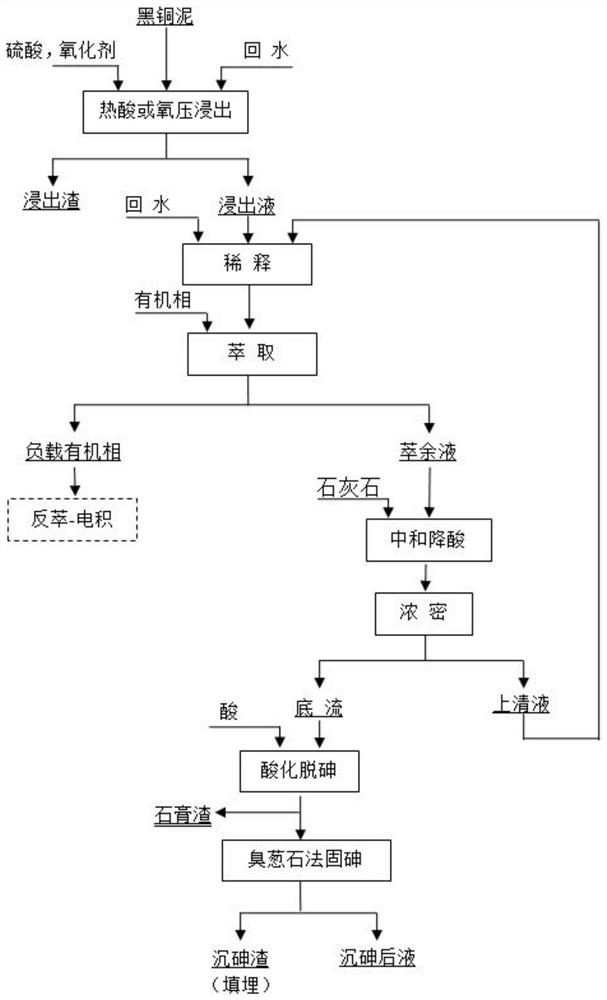

A treatment method, black copper slime technology, applied to the improvement of process efficiency, instruments, optics, etc., can solve the problems of high production cost, poor working environment, and difficult processing, so as to reduce the scale and cost, and reduce the risk of environmental pollution. The effect of high leaching rate of copper and arsenic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The main element content of the black copper mud sample: Cu 55.6%, As 33.7%, Bi 1.0%, Sb 1.3%, Pb 1.6%.

[0048] (1) Pressurized oxidation leaching, according to the liquid-solid ratio of 10, mix black copper mud with 80g / L sulfuric acid solution, add it to the autoclave, control the reaction temperature to 120°C, the oxygen partial pressure to 0.5MPa, and the reaction time to 2h; After completion, solid-liquid separation is carried out to obtain leaching liquid and leaching slag, and the leaching slag is returned to the smelting system;

[0049] (2) Extraction-electrowinning, the leaching solution contains Cu 6.7g / L, As 15g / L, pH value 1.9, the leaching solution diluted with backwater is extracted with the organic phase synthesized by 10% ZJ988+90% kerosene, compared O / A=2, time 5min, the loaded organic phase was washed with 3g / L sulfuric acid solution to obtain the washed loaded organic phase and raffinate, and the washed loaded organic phase was subjected to back ext...

Embodiment 2

[0056] The main element content of the black copper mud sample: Cu 55.6%, As 33.7%, Bi 1.0%, Sb 1.3%, Pb 1.6%.

[0057] (1) Hot acid oxidation leaching, according to the liquid-solid ratio of 20, the black copper mud is mixed with 50g / L sulfuric acid solution, the reaction temperature is controlled at 80°C, the reaction process is filled with air and the ratio is 1.5t / t 黑铜泥 Add 30% concentration of H 2 o 2 , the reaction time is 6 hours; after the reaction is completed, solid-liquid separation is carried out to obtain leachate and leaching slag, and the leaching slag is returned to the smelting system;

[0058] (2) Extraction-electrodeposition, the leaching solution contains Cu 9.3g / L, As 10.6g / L, pH value 1.7, the leaching solution is diluted with backwater, and the organic Phase extraction, control phase O / A=4, time 10min for extraction, then the loaded organic phase was washed with 5g / L sulfuric acid solution to obtain the loaded organic phase and raffinate after washing,...

Embodiment 3

[0064] The main element content of the black copper mud sample: Cu 36.2%, As 34.2%, Bi 1.5%, Sb 1.5%, Pb 2.0%.

[0065] (1) Pressurized oxidation leaching, according to the liquid-solid ratio of 6, the black copper mud and 140g / L sulfuric acid solution are mixed, put into the autoclave, the reaction temperature is controlled at 150°C, the oxygen partial pressure is 0.3MPa, and the reaction time is 3h; After the completion, the solid-liquid separation is carried out, the leaching slag is returned to the smelting system, and the leaching liquid is diluted and then enters the extraction system;

[0066] (2) Extraction-electrowinning, first dilute the leaching solution (Cu 3.8g / L, As 23g / L, pH 2.1) with backwater, then add 15% ZJ988+85% kerosene for extraction, compared to O / A=1.2, extraction time is 5min, then the loaded organic phase is washed with 5g / L sulfuric acid solution, and the washed loaded organic phase is back-extracted-electrodeposited to obtain electrode copper prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com