Embedded outer knurled nut and manufacturing method thereof

A technology of knurled nuts and manufacturing methods, which is applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve the problems of unsatisfactory, low material hardness, etc., and achieve the goal of reducing phase transition stress, high hardness, and reducing cracks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

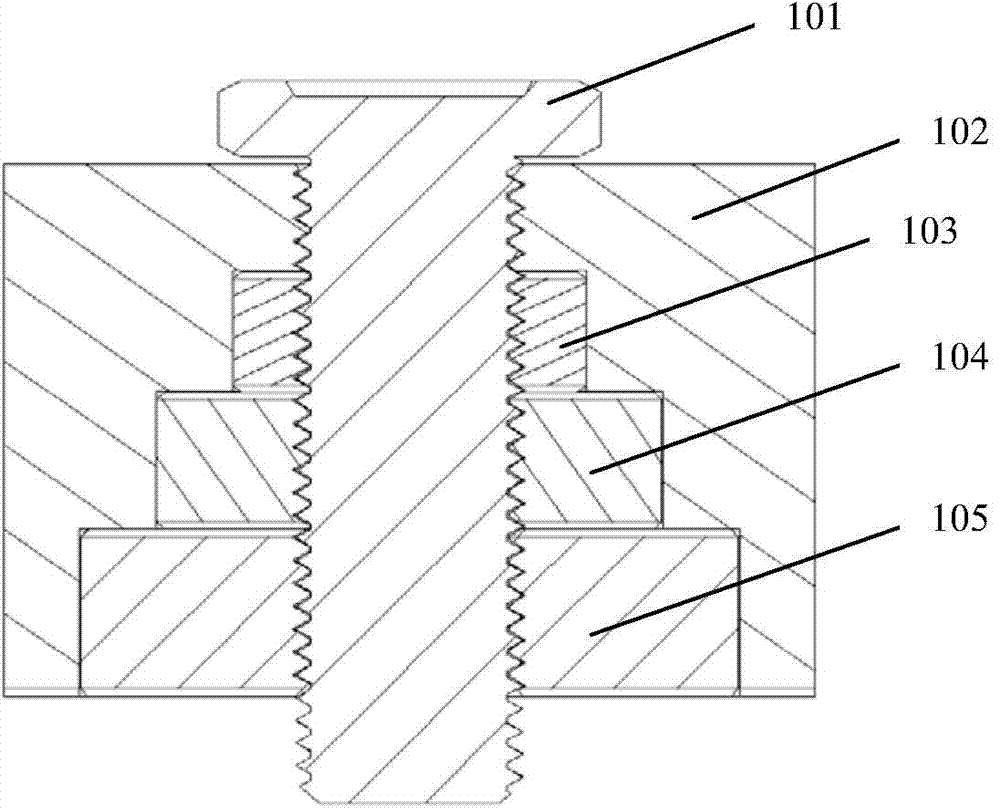

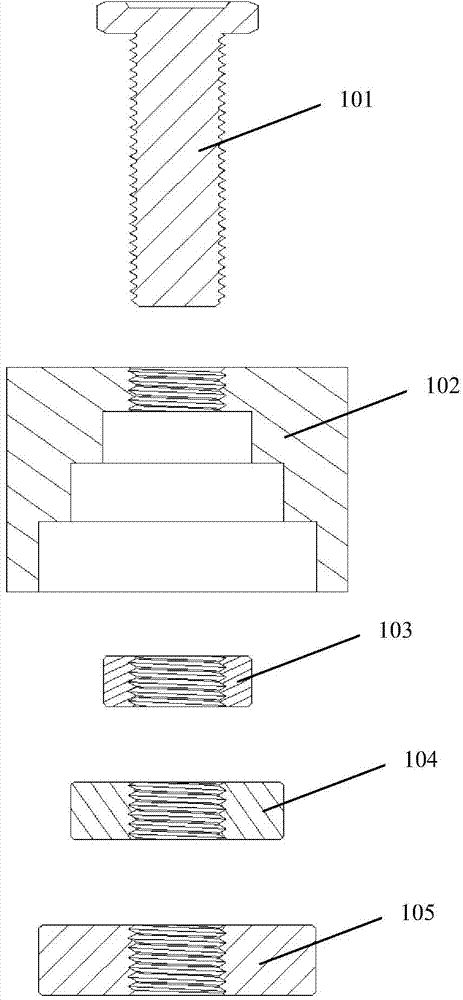

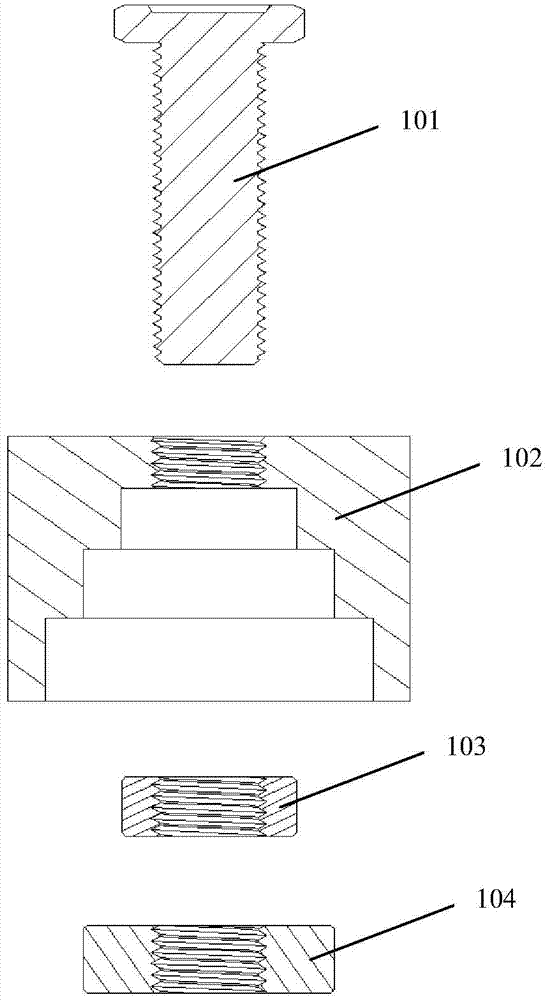

[0034] Such as figure 1 As shown, an embedded outer knurled nut is characterized in that it includes a plurality of inner nut bodies (103, 104, 105) and an outer nut body (102); the plurality of inner nut bodies and a The outer nut bodies are all provided with outer knurling (not shown); the centers of the plurality of inner nut bodies are hollow threaded cavities; the diameters of the threaded cavities of the plurality of inner nut bodies match the diameter of the bolt (101) ; When installed on bolts, the outer nut body and multiple inner nut bodies are installed in a stepped shape in the axial direction from top to bottom from the direction of the bolt head, and the radius of the lower inner nut body is larger than that of the upper inner nut body Radius; the sum of the thicknesses of the plurality of inner nut bodies is less than the radial length of the bolt; when installed on the bolt, the plurality of inner nut bodies are completely covered by the outer nut body; the cav...

Embodiment 2

[0056] Such as figure 1 As shown, an embedded outer knurled nut is characterized in that it includes a plurality of inner nut bodies (103, 104, 105) and an outer nut body (102); the plurality of inner nut bodies and a The outer nut bodies are all provided with outer knurling (not shown); the centers of the plurality of inner nut bodies are hollow threaded cavities; the diameters of the threaded cavities of the plurality of inner nut bodies match the diameter of the bolt (101) ; When installed on bolts, the outer nut body and multiple inner nut bodies are installed in a stepped shape in the axial direction from top to bottom from the direction of the bolt head, and the radius of the lower inner nut body is larger than that of the upper inner nut body Radius; the sum of the thicknesses of the plurality of inner nut bodies is less than the radial length of the bolt; when installed on the bolt, the plurality of inner nut bodies are completely covered by the outer nut body; the cav...

Embodiment 3

[0076] Such as figure 1As shown, an embedded outer knurled nut is characterized in that it includes a plurality of inner nut bodies (103, 104, 105) and an outer nut body (102); the plurality of inner nut bodies and a The outer nut bodies are all provided with outer knurling (not shown); the centers of the plurality of inner nut bodies are hollow threaded cavities; the diameters of the threaded cavities of the plurality of inner nut bodies match the diameter of the bolt (101) ; When installed on bolts, the outer nut body and multiple inner nut bodies are installed in a stepped shape in the axial direction from top to bottom from the direction of the bolt head, and the radius of the lower inner nut body is larger than that of the upper inner nut body Radius; the sum of the thicknesses of the plurality of inner nut bodies is less than the radial length of the bolt; when installed on the bolt, the plurality of inner nut bodies are completely covered by the outer nut body; the cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com