A kind of anti-loosening nut and its manufacturing method

A technology for preventing loosening of nuts and nut bodies, which is applied to nuts, manufacturing tools, screws, etc., can solve the problems of environmental impact, low material hardness, and inability to prevent loosening methods, and achieves reduction of phase transformation stress, high hardness, and reduced effect of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

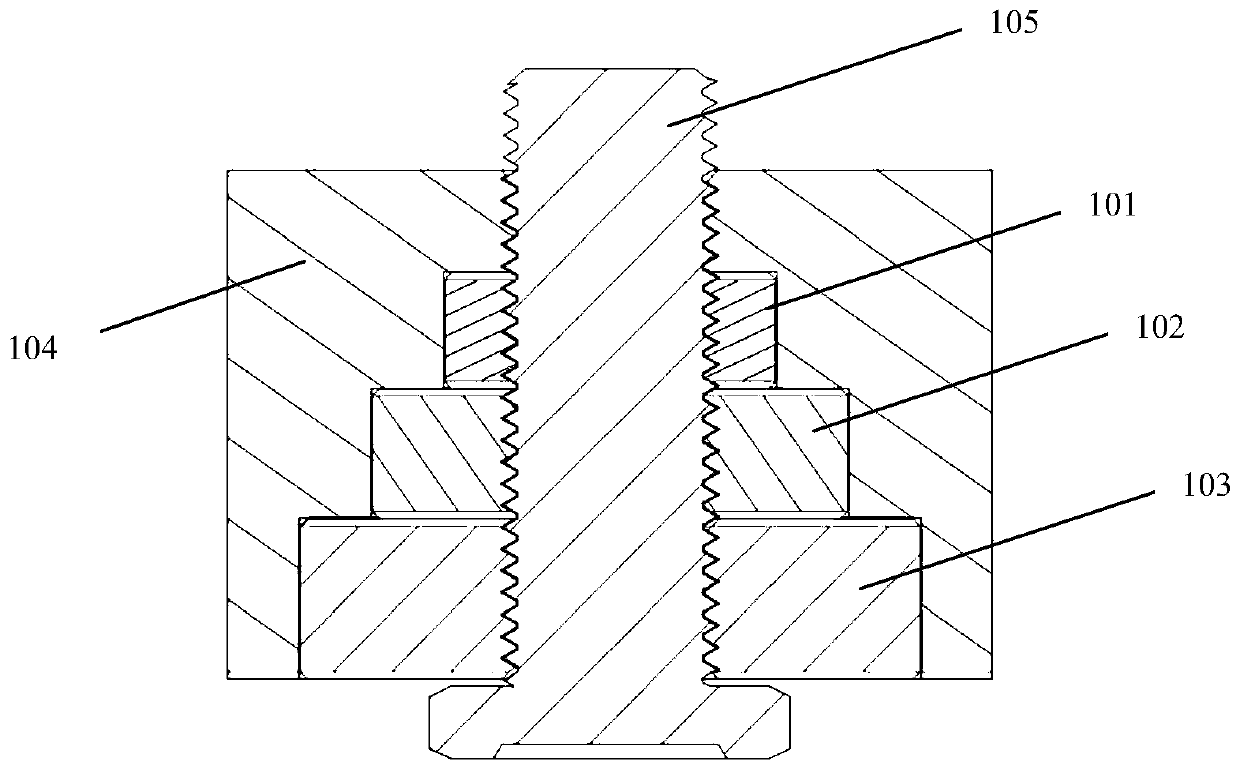

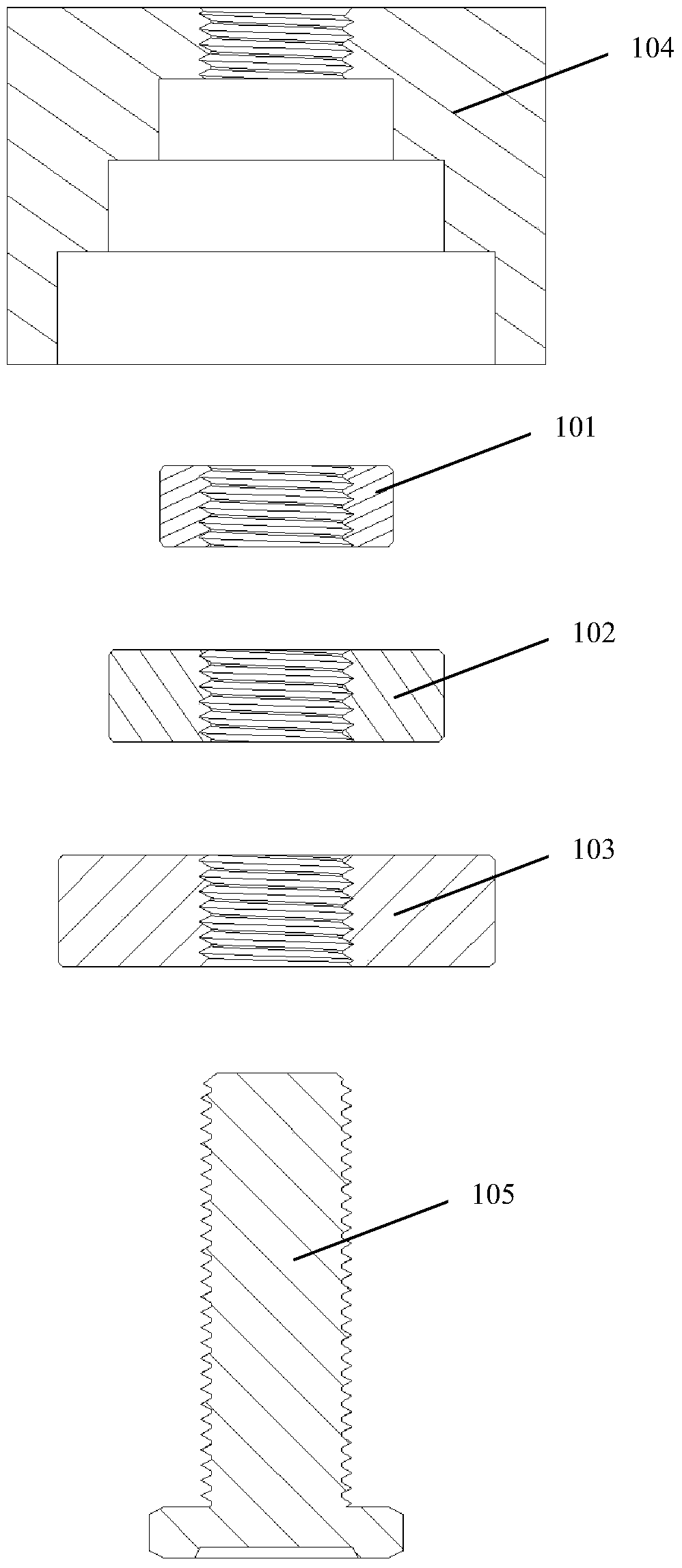

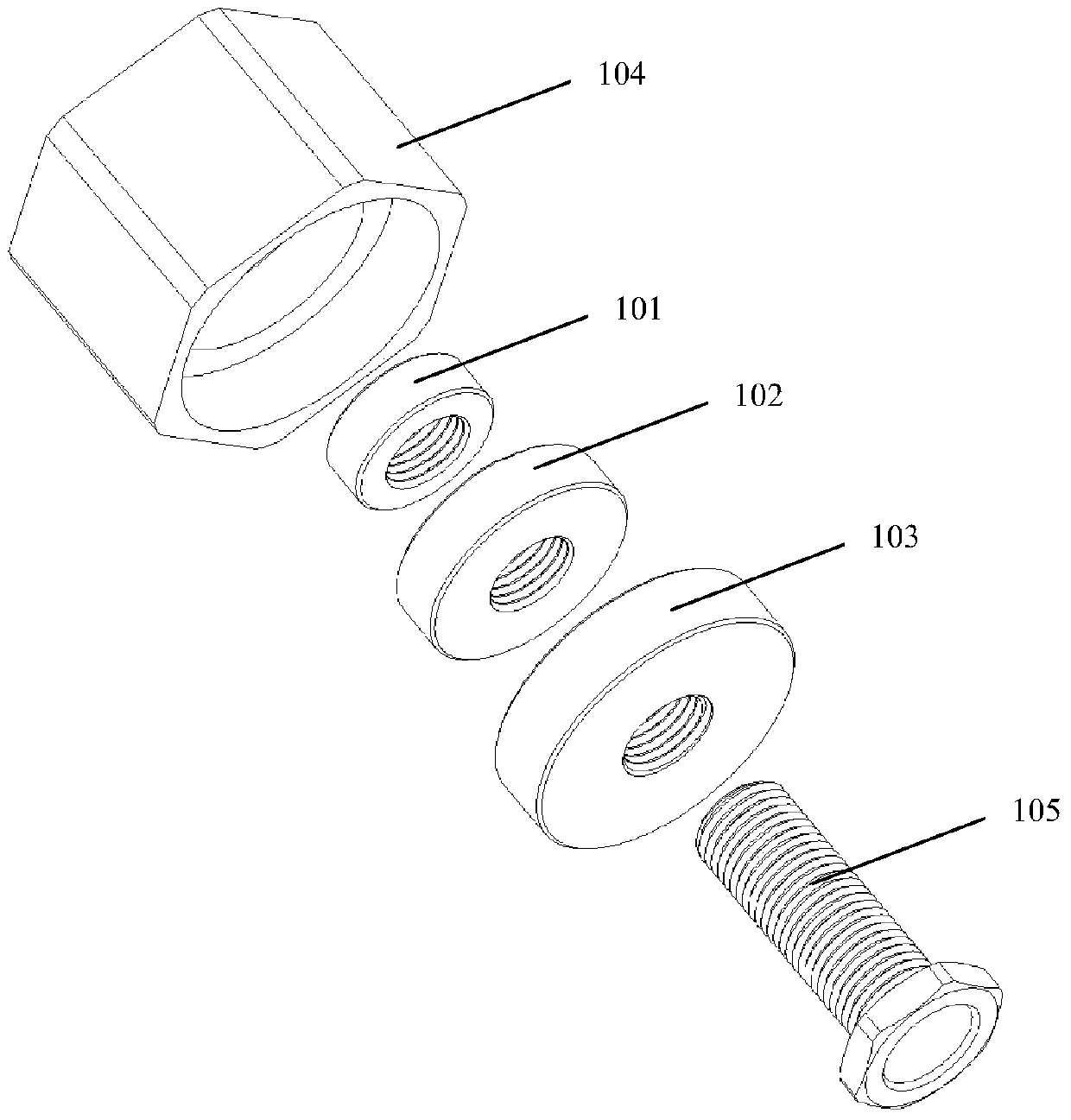

[0032] Such as Figure 1-4 As shown, the locknut includes a plurality of inner nut bodies (101, 102, 103) and an outer nut body (104); the centers of the plurality of inner nut bodies are hollow threaded cavities; The diameter of the threaded cavity of the inner nut body matches the diameter of the bolt (105); when installed on the bolt, the outer nut body and multiple inner nut bodies are installed in a stepped form along the axial direction from the top to the bottom of the bolt tail; it is located in the lower layer The radius of the inner nut body is greater than the radius of the upper inner nut body; the sum of the thicknesses of the plurality of inner nut bodies is less than the axial length of the bolt; when installed on the bolt, the plurality of inner nut bodies are completely covered by the outer layer The nut body is covered; the cavity of the outer nut body is hollow and inverted in the shape of a ladder along the axial section; the height of each step from bottom...

Embodiment 2

[0049] Such as Figure 1-4 As shown, the locknut includes a plurality of inner nut bodies (101, 102, 103) and an outer nut body (104); the centers of the plurality of inner nut bodies are hollow threaded cavities, and the outer circumference is a cylinder The diameter of the threaded cavity of the plurality of inner nut bodies matches the diameter of the bolt (105); when installed on the bolt, the outer nut body and the plurality of inner nut bodies are axially formed Ladder-like installation; the radius of the inner nut body on the lower layer is larger than the inner nut body radius on the upper layer; the sum of the thicknesses of the multiple inner nut bodies is less than the axial length of the bolt; when installed on the bolt, multiple inner layers The nut body is completely covered by the outer nut body; the cavity of the outer nut body is hollow and inverted along the axial section; the height of each step from bottom to top in the axial direction corresponds to the th...

Embodiment 3

[0064] Such as Figure 1-4 As shown, the locknut includes a plurality of inner nut bodies (101, 102, 103) and an outer nut body (104); the centers of the plurality of inner nut bodies are hollow threaded cavities; The diameter of the threaded cavity of the inner nut body matches the diameter of the bolt (105); when installed on the bolt, multiple inner nut bodies are installed in a ladder shape from bottom to top along the axial direction, and the inner nut body on the lower layer has a larger radius than that on the upper layer. The radius of the inner layer nut body; the sum of the thicknesses of the plurality of inner layer nut bodies is less than the axial length of the bolt; when installed on the bolt, the plurality of inner layer nut bodies are completely covered by the outer layer nut body; the outer layer The cavity of the nut body is in the shape of a hollow inverted ladder along the axial section; the height of each step from bottom to top in the axial direction corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com