Annular hanging platform for mounting stove shell of hot-blast stove, and mounting and dismounting method thereof

A ring-shaped platform and hot blast furnace technology, which is applied to the scaffolding of building structure support, building structure support, building structure support, etc., can solve the problems of affecting the construction progress, high cost, and large materials, so as to speed up the construction progress and facilitate processing and production , to ensure the effect of life safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

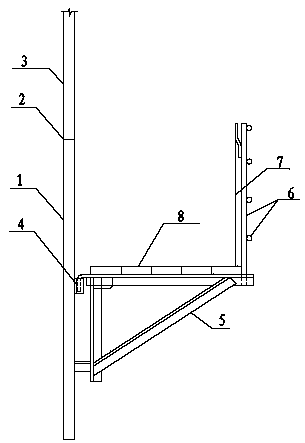

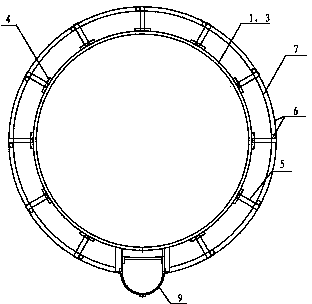

[0047] A ring-shaped hanging platform for hot blast furnace shell installation

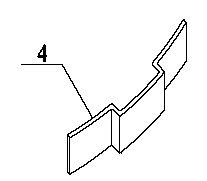

[0048] see now Figure 1 ~ Figure 3 , figure 1 It is the elevation view of the annular platform of the embodiment of the present invention, figure 2 It is a schematic diagram of the hanging ear structure of the embodiment of the present invention, image 3 It is the plan view of the annular platform of the embodiment of the present invention. As shown in the figure, the hanging lug 4 of the annular hanging platform installed on the hot blast furnace shell is made of steel plate, and is in the shape of an arc, 200mm long, 80mm wide, and 6mm thick, and is welded and fixed along the circumference of the annular furnace shell On the outer wall of the annular furnace shell, the hanging lug is 1.2m away from the upper opening of the first belt furnace shell, and the circumferential distance between the hanging lugs is 1.5m.

[0049] The tripod 5 is made of ∠50×5mm angle steel, with a width of 1m an...

Embodiment 2

[0054] An installation method of a ring-shaped hanging platform for installation on the outer wall of a hot blast stove shell

[0055] An installation method for an annular hanging platform installed on the outer wall of a hot blast stove shell, characterized in that it includes the following steps:

[0056] a. After the first belt furnace shell 1 is assembled and welded on the ground, the prefabricated hanging lug 4 is welded and fixed on the outer wall of the furnace shell along the circumference of the furnace shell. The distance between the hanging lug and the upper opening of the first belt furnace shell 1 is 1.2m. The spacing is 1.5m.

[0057] b. Insert the hooks of the prefabricated tripod 5 into the hanging lugs 4, arrange them along the circumference of the first belt furnace shell 1 with a distance of 1.5m, and weld and fix the lower end legs on the furnace shell.

[0058] c. Lay steel springboards 8 above the two adjacent tripods 5, and tie the ends of the tripods ...

Embodiment 3

[0066] An installation method of a ring-shaped hanging platform for installation on the inner wall of a hot blast stove shell

[0067] In this embodiment, except that the hanging lug 4 is welded and fixed on the inner wall of the annular furnace shell, the tripod 5 is arranged along the circumference of the inner wall of the first belt furnace shell 1, and cooperates with the railing 6, the safety net 7, the steel springboard 8 and the steel ladder 9 in the annular furnace shell. Except that the ring-shaped hanging platform is set on the inner wall, all the others are the same as in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com