Ultra-silent diesel generating set

A technology for diesel generator sets and diesel engines, applied in engine components, machines/engines, mechanical equipment, etc., can solve problems such as cooling fan noise, and achieve the effects of reducing noise, extending the exhaust path, and improving noise reduction effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

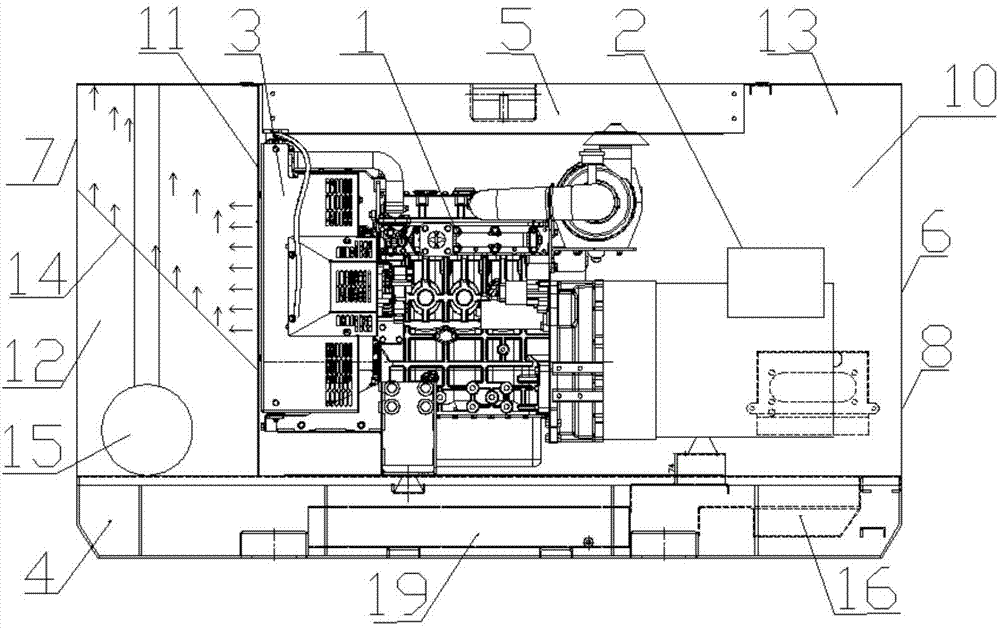

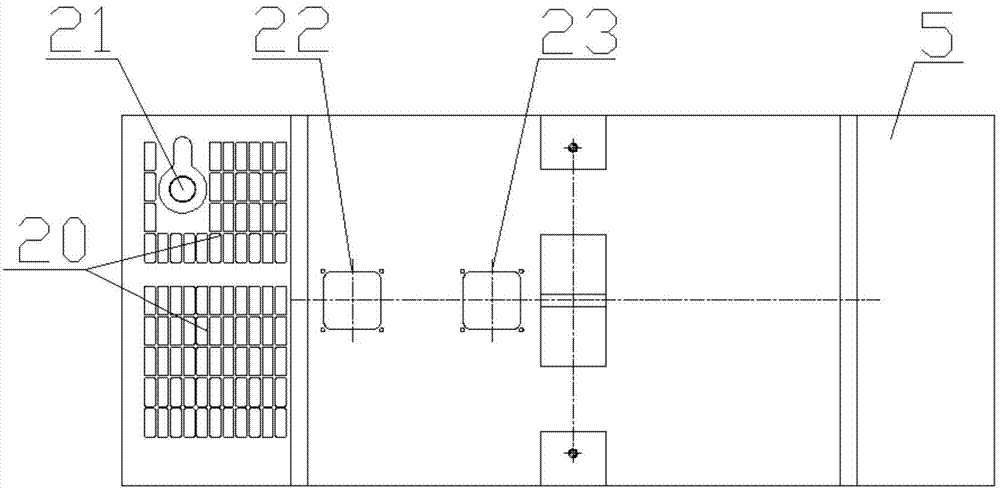

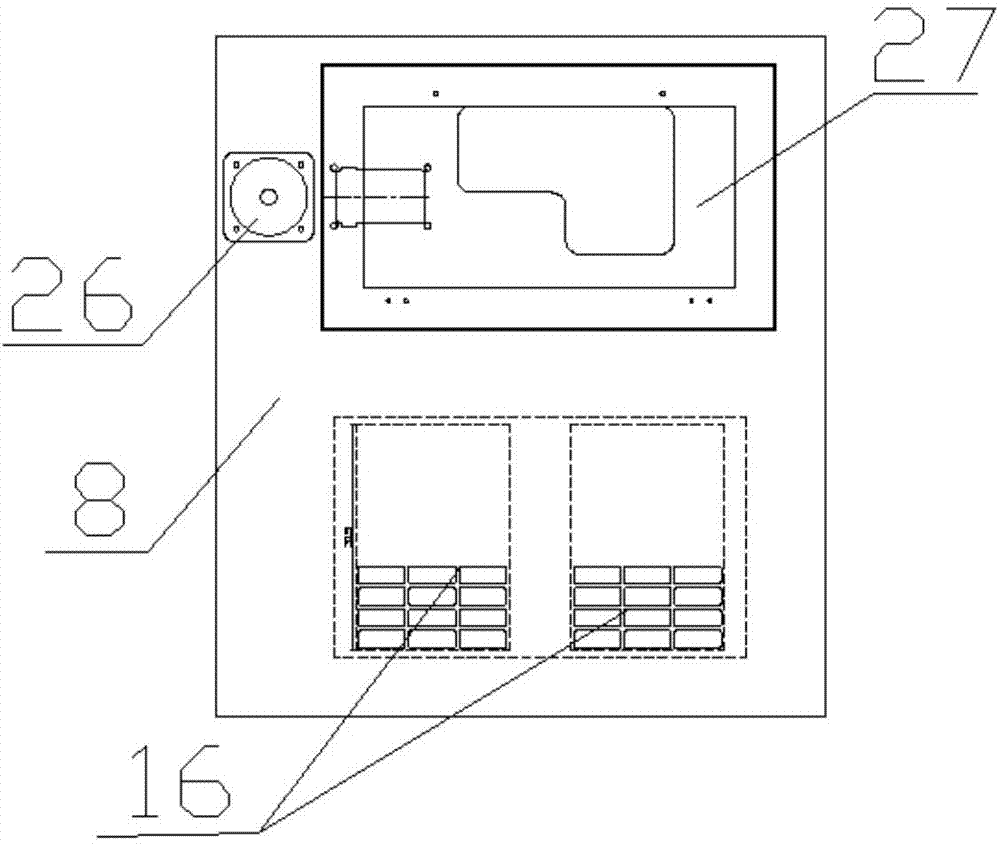

[0032] Such as Figure 1-8 Shown is a 30kW ultra-quiet diesel generator set, the output end of diesel engine 1 is connected to generator 2, the free end of diesel engine 1 is connected to water tank 3, diesel engine 1 and generator 2 are connected to base 4 respectively, and the top cover 5 is located between diesel engine 1 and generator 2. Above the water tank 3, the diesel engine 1, the generator 2, and the water tank 3 are surrounded by a shell 6, which includes a front sealing plate 7, a rear sealing plate 8, a door plate 9, and a rear plate 10. The inner surface of the shell 6 is covered with sound-absorbing cotton 18. An oil tank 19 is installed on the base 4. The front end of the water tank 3 is connected with a water tank baffle 11. The water tank baffle 11 is a steel plate with a thickness of 2 mm. One side of the water tank baffle 11 is the front box body 12 and the other side is the rear box body 13 , one end of the front box body 12 is connected to the front seali...

Embodiment 2

[0036] The ultra-quiet diesel generator set structure and working process adopted in embodiment 2 are the same as in embodiment 1, and the different relevant parameters of embodiment 2 are as follows:

[0037] (1) The water tank baffle plate 11 is a steel plate with a thickness of 4mm;

[0038] (2) The wind deflector inclined plate 14 is a steel plate with a thickness of 4mm;

[0039] (3) The angle of inclination of the wind deflector inclined plate 14 is 120 degrees;

[0040] (4) The wind guide and sound insulation board 17 is a steel plate with a thickness of 4mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com