A method for detecting the drying degree of Gongfu black tea

A technology of Gongfu black tea and drying degree, applied in the direction of color/spectral characteristic measurement, etc., can solve problems affecting quality stability, etc., and achieve the effect of stable quality, high detection repeatability, and scientific drying degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

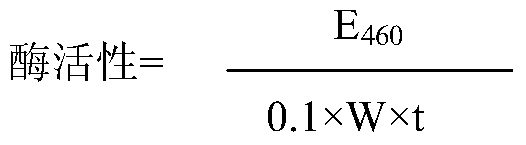

Method used

Image

Examples

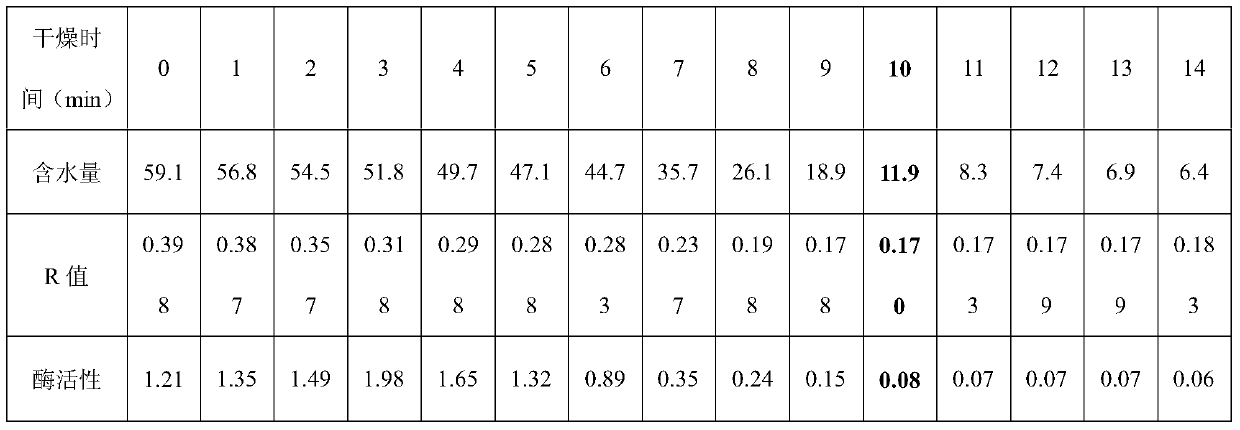

Embodiment 1

[0018] Process Gongfu black tea with one bud and two leaves Yingshuang at the end of autumn, and control the drying temperature at 130°C. The end of fermentation is recorded as 0 min of drying. After that, samples are taken every 1 min, and the R value of the sample is measured with a color difference meter. When the R value decreases to the lowest value, the Take dry leaf samples and measure PPO activity at the same time.

[0019] Measuring method: Take about 50g of fermented leaves and lay them flat on a small white porcelain plate with a thickness of 0.5-2cm. It is advisable not to produce transmission, and select different measurement points. In this embodiment, 12 measuring points are selected to determine the R value of the dried leaves. A colorimetric method was used to detect the PPO activity of the samples.

[0020] ①Preparation of enzyme solution: Take 0.5g of frozen leaves, add 0.3g of insoluble polyvinylpyrrolidone, 2g of quartz sand and an appropriate amount of p...

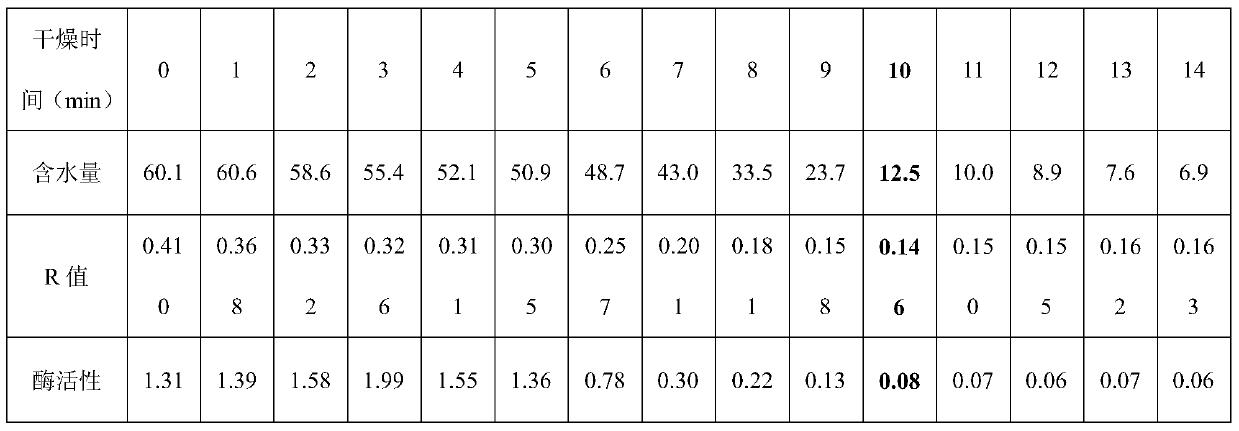

Embodiment 2

[0029] Process Gongfu black tea with one bud and two leaves Yingshuang at the end of autumn, and control the drying temperature at 130°C. The end of fermentation is recorded as 0 min of drying. After that, samples are taken every 1 min, and the R value of the sample is measured with a color difference meter. When the R value decreases to the lowest value, the Take dry leaf samples and measure PPO activity at the same time.

[0030] Measuring method: Take about 50g of fermented leaves and lay them flat on a small white porcelain plate with a thickness of 0.5-2cm. It is advisable not to produce transmission, and select different measurement points. In this embodiment, 12 measuring points are selected to determine the R value of the dried leaves. A colorimetric method was used to detect the PPO activity of the samples. According to the change of R value and PPO activity, the degree of dryness can be determined, and the measurement results are shown in the table below:

[0031] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com