A Prediction Method of Appearance Bubbles in Hardened Concrete

A technology of concrete and air bubbles, which is applied in the field of material engineering, can solve problems such as unfavorable and impactful engineering quality control, and achieve the effect of low cost and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

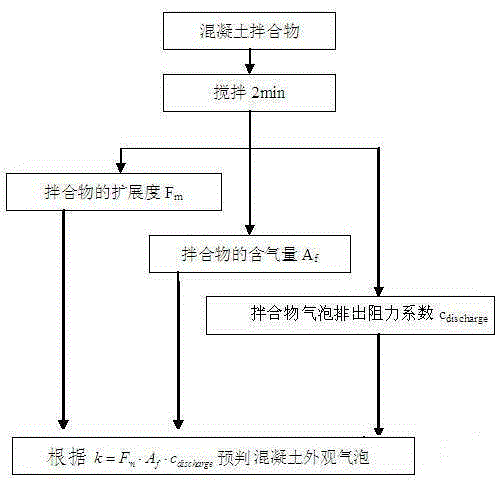

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Prediction of air bubbles in laboratory concrete appearance

[0019] The laboratory concrete mix ratio is shown in Table 1, and the admixtures are changed to obtain different hardened concrete appearance bubbles. Concrete mixture is predicted according to the method of the present invention:

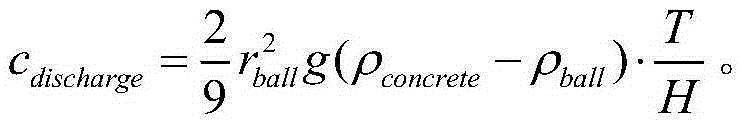

[0020] (1) Take the freshly mixed concrete mixture and divide it into three parts evenly after stirring for 2 minutes. One part shall be tested according to GB / T50080 for expansion m , the unit is mm, one part is tested according to GB / T50080 for gas content A f , the unit is %, a test bubble discharge resistance coefficient c discharge , the unit is N·s / m 2 ; Bubble discharge resistance coefficient c discharge The test method: Prepare a barrel-shaped container with a diameter of 30cm and a height of 60cm. The lower end of the container is closed and the upper end is open; one end with a spring of 20cm has a radius of r ball (unit: m)(r ball ≤0.015m), the density ...

Embodiment 2

[0030] Example 2: Prejudgment of concrete appearance bubbles in a municipal project

[0031] Using the concrete mix ratio of a municipal project as shown in Table 4, the quality of hardened concrete appearance bubbles is predicted. Two different concrete admixtures are used in the mix ratio to optimize the concrete appearance quality control technical scheme. The method of the present invention is used for pre-judgment, and the pre-judgment method is the same as in Example 1. The results of the parameter tests of the concrete mixture and the pre-judgment of appearance bubbles are shown in Table 5. After the concrete formwork is removed, the image recognition processing technology is used to conduct statistics on the appearance of hardened concrete bubbles. The statistical results are shown in Table 6.

[0032] Table 4 Concrete mix ratio (kg / m 3 )

[0033] serial number

[0034] Table 5 Test results of various parameters of concrete mixture and prediction results ...

Embodiment 3

[0039] Example 3: Prediction of concrete appearance bubbles in a bridge project

[0040] The concrete mix ratio of a bridge project is used as shown in Table 7 to predict the appearance of hardened concrete bubbles. The mix ratio not only introduces the double mixing of fly ash and mineral powder, which makes the system more complex, but also uses two different concrete admixtures. The method of the present invention is used for pre-judgment, and the pre-judgment method is the same as that in Example 1. The results of the test of various parameters of the concrete mixture and the pre-judgment of appearance bubbles are shown in Table 8. After the concrete formwork is removed, the image recognition processing technology is used to conduct statistics on the appearance of hardened concrete bubbles. The statistical results are shown in Table 9.

[0041] Table 7 Concrete mix ratio (kg / m 3 )

[0042] serial number

[0043] Table 8 Test results of various parameters of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com