Capacitive touch screen

A capacitive touch screen and conductive layer technology, which is applied in the input/output process of electrical digital data processing, instruments, and data processing, etc. The effect of improving and reducing the difficulty of driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

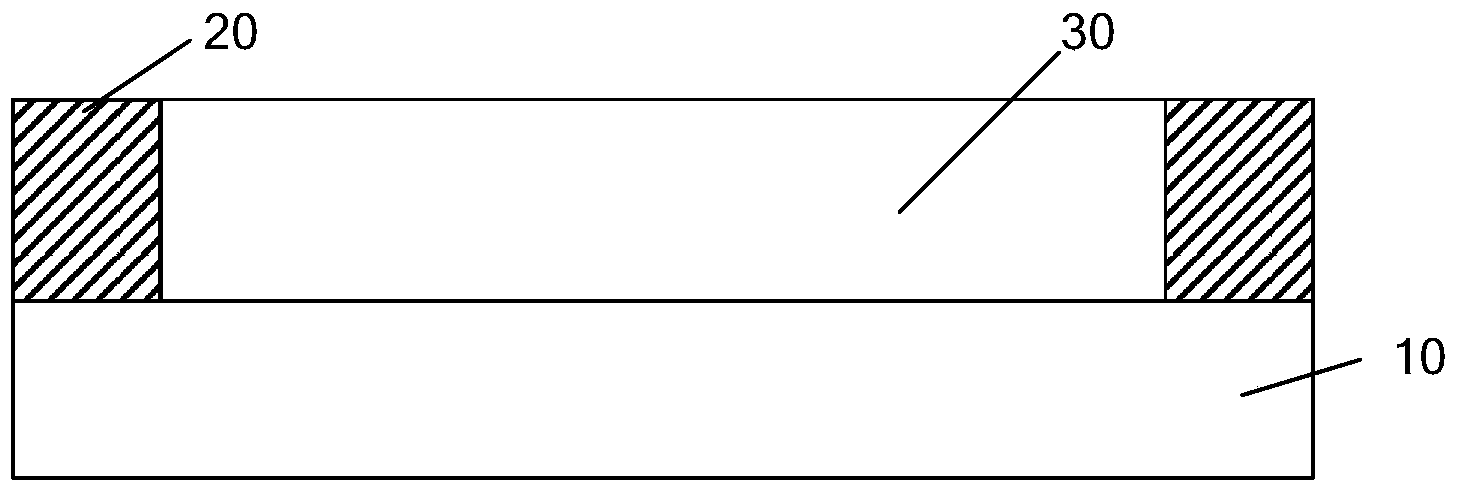

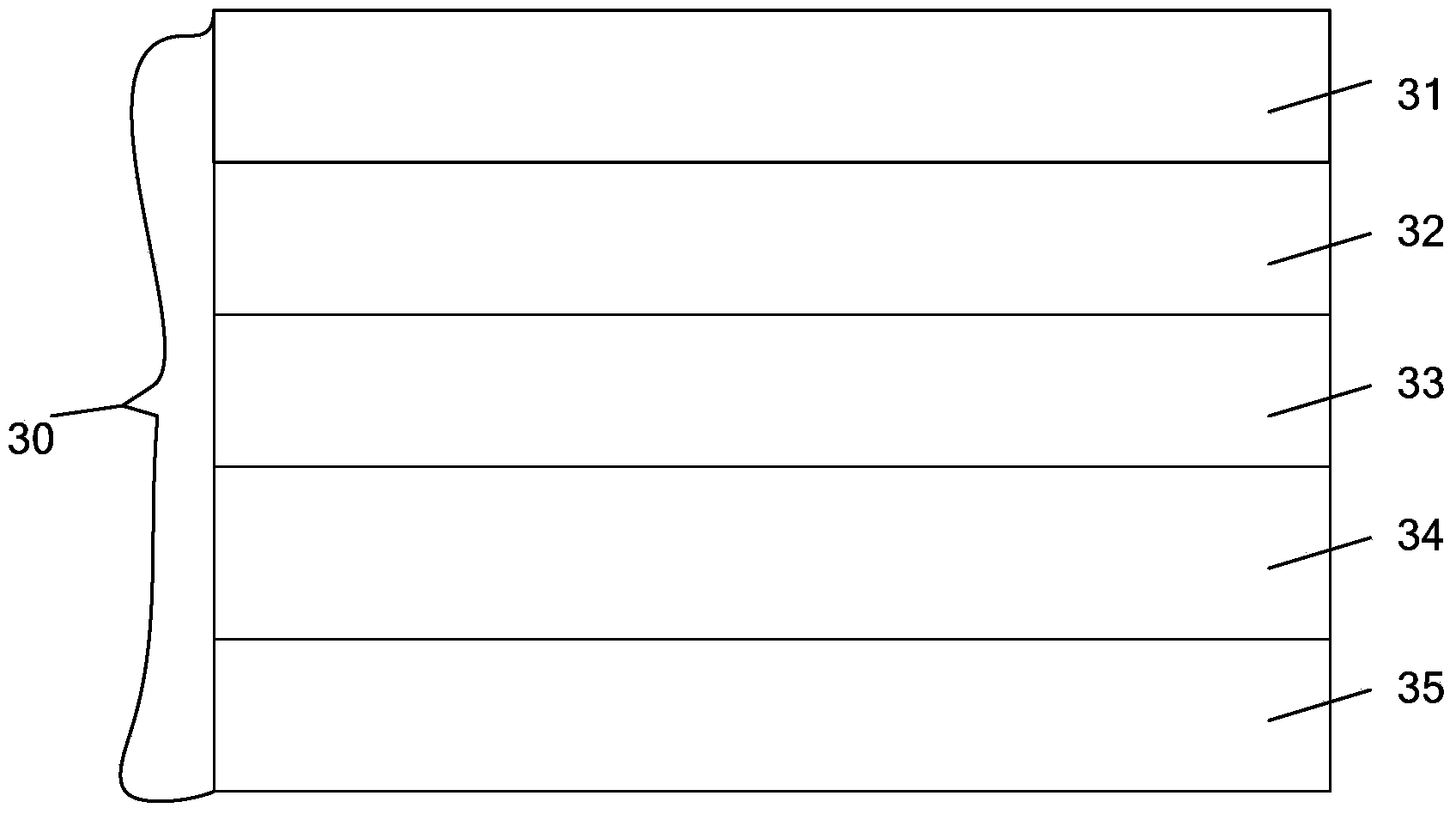

[0048] set up figure 1 As shown in the capacitive touch screen, the structure of the conductive pattern layer is as follows figure 2 As shown, the thickness and material of each first ITO conductive layer 31, the first anti-oxidation layer 32, metal layer 33, the second anti-oxidation layer 34 and the second ITO conductive layer 35 are shown in Table 1, and the resistance of the conductive pattern layer Ratio, light transmittance and sensitivity of capacitive touch screen are tested, and the test results are shown in Table 2.

Embodiment 2

[0050] set up figure 1 As shown in the capacitive touch screen, the structure of the conductive pattern layer is as follows figure 2 As shown, the thickness and material of each first ITO conductive layer 31, the first anti-oxidation layer 32, metal layer 33, the second anti-oxidation layer 34 and the second ITO conductive layer 35 are shown in Table 1, and the resistance of the conductive pattern layer Ratio, light transmittance and sensitivity of capacitive touch screen are tested, and the test results are shown in Table 2.

Embodiment 3

[0052] set up figure 1 As shown in the capacitive touch screen, the structure of the conductive pattern layer is as follows figure 2 As shown, the structure of the conductive pattern layer is as figure 2 As shown, the thickness and material of each first ITO conductive layer 31, the first anti-oxidation layer 32, metal layer 33, the second anti-oxidation layer 34 and the second ITO conductive layer 35 are shown in Table 1, and the resistance of the conductive pattern layer Ratio, light transmittance and sensitivity of capacitive touch screen are tested, and the test results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap