Motor vehicle having a high-voltage power supply system

A technology for power supply system and motor vehicle, which is applied in electric vehicles, electric braking system, electric vehicle charging technology, etc., to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

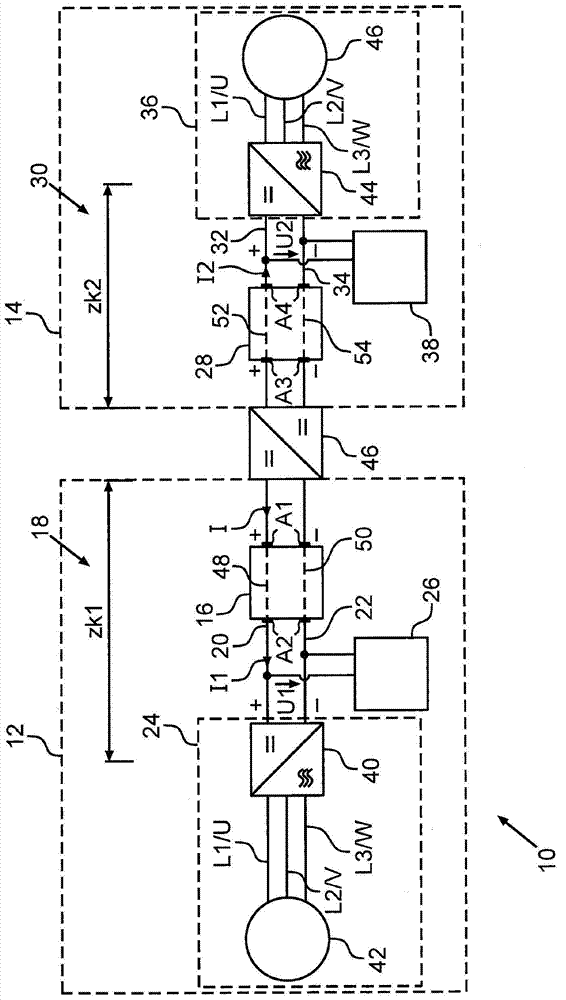

[0023] FIG. 1 shows the high-voltage electrical system of a motor vehicle 10 . Motor vehicle 10 may be, for example, a passenger car. A high-voltage power supply system 12 is installed at the front and a high-voltage power supply system 14 is installed at the rear in the motor vehicle 10 . Here, the high-voltage power supply system refers to the entire electrical equipment consisting of the power supply, consumers and connecting wires.

[0024] The preceding high-voltage power supply system 12 has a high-voltage power source 16, an intermediate circuit 18 (with a conductor 20 for positive potential and a conductor 22 for negative potential) and a plurality of electrical high-voltage components, which are shown in more detail in the drawing Electric traction drive 24 . Further electrical high-voltage components 26 are represented in the drawing by single boxes.

[0025] The latter high-voltage supply system 14 similarly comprises a high-voltage power supply 28, an intermedia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com