Reaction tank

A technology of reaction tank and tank body, which is applied in the field of fixed reactors, and can solve the problems of affecting the reaction of the reaction tank, wasting raw salt resources, and high flow rate of brine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

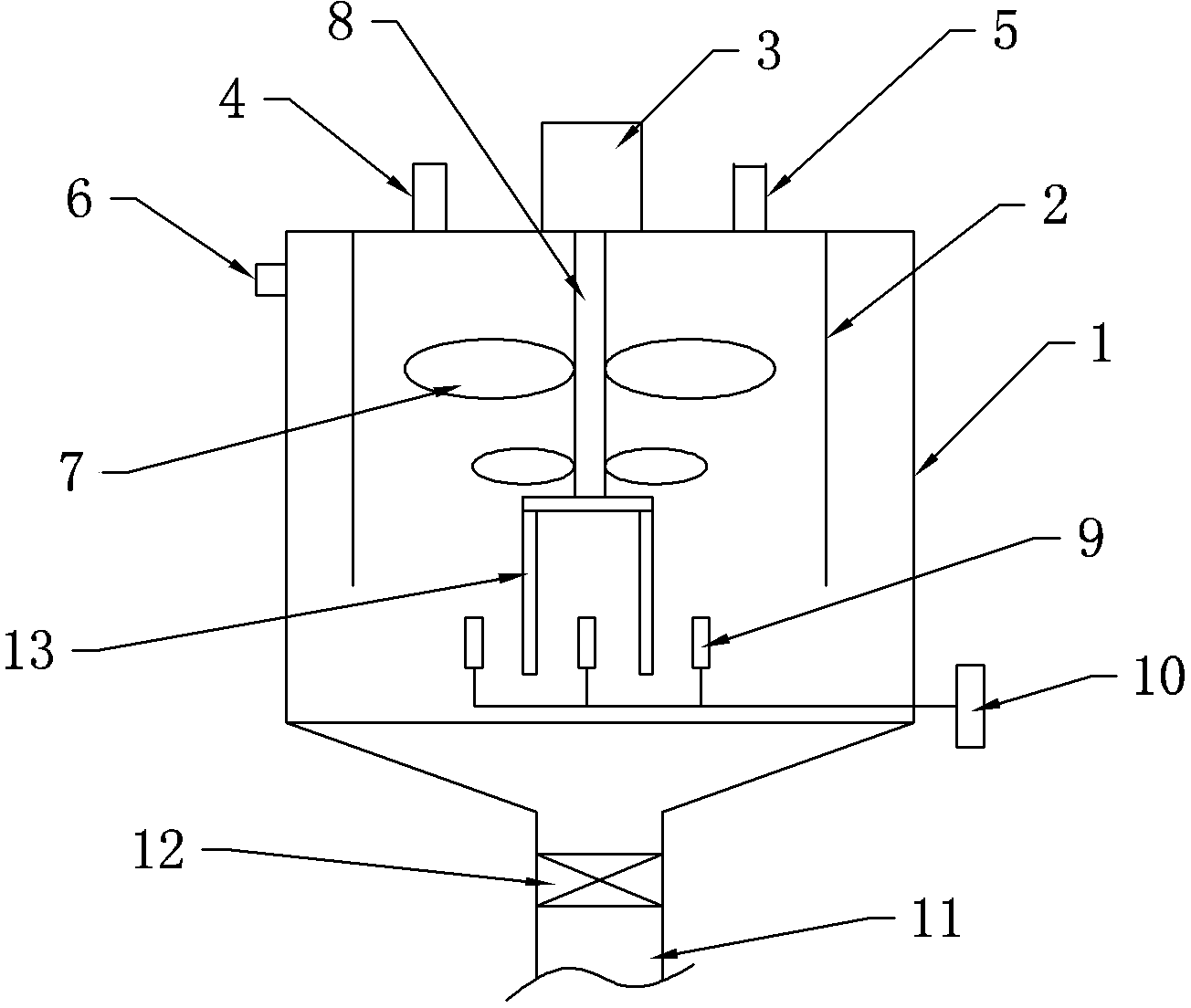

[0013] Such as figure 1 As shown, a reaction tank includes a tank body 1, a motor 3, a stirring blade 7 and a baffle plate 2, the upper end of the baffle plate 2 is connected to the top of the tank body 1 to form a settling chamber with an open lower end, and the top of the tank body 1 is One side is provided with a brine inlet 4 connected to the settling chamber, and the other side is provided with a refined agent inlet 5 connected with the settling chamber. The upper part of the tank body 1 is also provided with a brine outlet 6 located outside the settling chamber. The motor 3 is installed on the top of the tank body 1 to stir The blade 7 extends into the tank body 1, and the output end of the motor 3 is connected with the stirring blade 7 through the rotating shaft 8, wherein, the bottom of the tank body 1 is funnel-shaped, and a mud discharge pipe 11 is provided at the bottom, and the mud discharge pipe 11 is provided with a discharge pipe. The mud valve 12 and three dist...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap