RhPdPt metal nanoalloy catalyst and application thereof

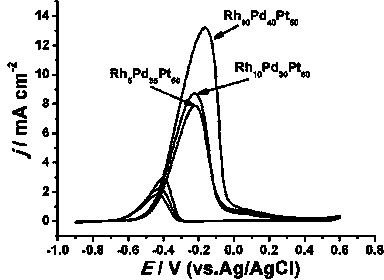

A ternary metal, nano-alloy technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, nanotechnology, etc., can solve the problem that ternary metal nano-alloy catalysts have not been reported. , to achieve the effect of superior catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Rh 10 PD 30 Pt 60 The preparation of ternary alloy nano-catalyst is as follows

[0025] (1) Configuration of the solution

[0026] H 2 PtCl 6 、Na 2 PdCl 4 and RhCl 3 Prepare 0.1 mol / L solution respectively, citric acid monohydrate and CTAC prepare 0.22 mol / L solution;

[0027] (2) Preparation of flocculent solution

[0028] Take 4.5 ml of 0.22 mol / L citric acid monohydrate and 4.5 ml of 0.22 mol / L CTAC, and then add 100ul of RhCl in proportion 3 (0.1 mol / L), 300 ul of Na 2 PdC 4 and 600 ul of H 2 PtCl 6 solution. At room temperature, stir magnetically to form a flocculent solution;

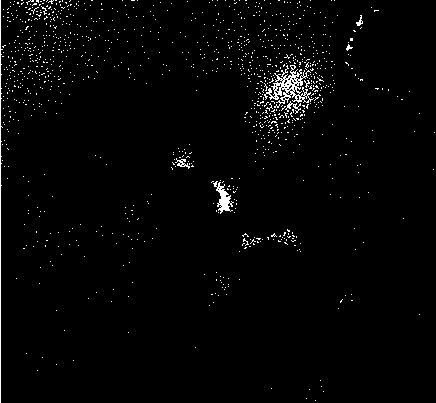

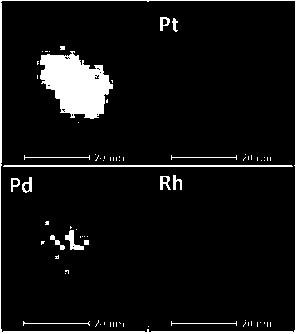

[0029] (3) Island structure Rh 10 PD 30 Pt 60 Preparation of Ternary Alloy Catalyst

[0030] Transfer the flocculent solution in step (2) to a 15 ml hydrothermal reaction kettle, react at 180 °C for 60 minutes, cool to room temperature, wash the obtained precipitate with ultrapure water 4 times, and then place it in a vacuum dryer dry in medium to obtain an island-like R...

Embodiment 2

[0032] Rh 10 PD 40 Pt 50 The preparation of ternary alloy nano-catalyst is as follows

[0033] (1) Configuration of the solution

[0034] H 2 PtCl 6 、Na 2 PdCl 4 and RhCl 3 Prepare 0.1 mol / L solution respectively, citric acid monohydrate and CTAC prepare 0.22 mol / L solution;

[0035] (2) Preparation of flocculent solution

[0036] Take 4.5 ml of 0.22 mol / L citric acid monohydrate and 4.5 ml of 0.22 mol / L CTAC, and then add 100 ul of RhCl in proportion 3 (0.1 mol / L), 400 ul of Na 2 PdCl 4 and 500 ul of H 2 PtCl 6 solution. At room temperature, stir magnetically to form a flocculent solution;

[0037] (3) Island structure Rh 10 PD 40 Pt 50Preparation of Ternary Alloy Catalyst

[0038] Transfer the flocculent solution in step (2) to a 15 ml hydrothermal reaction kettle, react at 180°C for 60 minutes, cool to room temperature, wash the obtained precipitate with ultrapure water 4 times, and then place it in a vacuum desiccator dry in medium to obtain an island-l...

Embodiment 3

[0040] Rh 10 PD 70 Pt 120 The preparation of ternary alloy nano-catalyst is as follows

[0041] (1) Configuration of the solution

[0042] H 2 PtCl 6 、Na 2 PdCl 4 and RhCl 3 Prepare 0.1 mol / L solution respectively, citric acid monohydrate and CTAC prepare 0.22 mol / L solution;

[0043] (2) Preparation of flocculent solution

[0044] Take 4.5 ml of 0.22 mol / L citric acid monohydrate and 4.5 ml of 0.22 mol / L CTAC, and then add 50 ul of RhCl in proportion 3 (0.1mol / L), 350 ul of Na 2 PdCl 4 and 600 ul of H 2 PtCl 6 solution. At room temperature, stir magnetically to form a flocculent solution;

[0045] (3) Island structure Rh 10 PD 70 Pt 120 Preparation of Ternary Alloy Catalyst

[0046] Transfer the flocculent solution in step (2) to a 15 ml hydrothermal reaction kettle, react at 180 °C for 60 minutes, cool to room temperature, wash the obtained precipitate with ultrapure water 4 times, and then place it in a vacuum dryer dry in medium to obtain an island-like...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com