Method for welding pump and motor for compressor shell

A welding method and compressor pump technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of easily damaged compressor casing and motor, restricting production line production efficiency, and prone to danger, so as to avoid Lack of sealing, high strength, and the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below with reference to the drawings and embodiments.

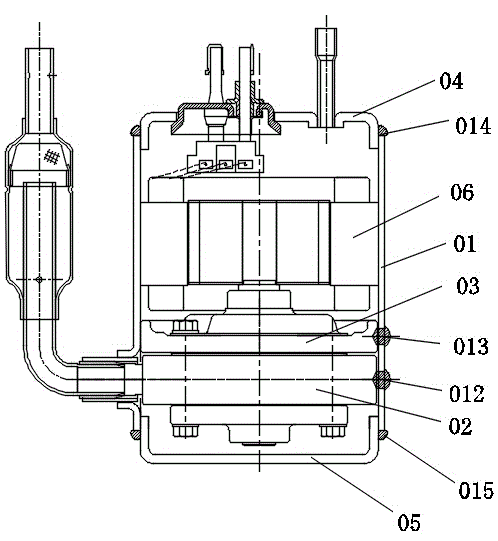

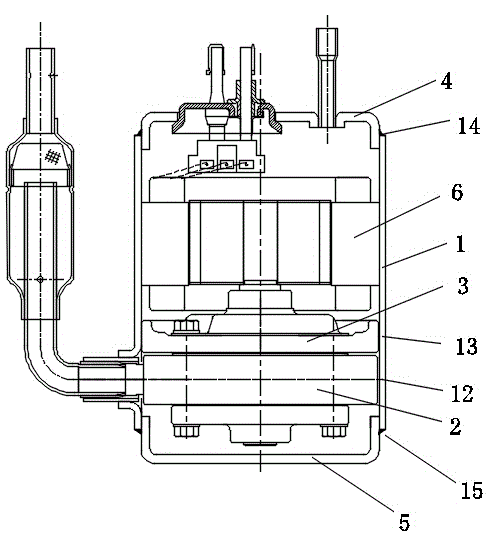

[0033] Please refer to figure 2 , the embodiment of the present invention includes:

[0034] A welding method for a pump and motor of a compressor shell, using a laser welding device to weld a compressor pump cylinder 2, a pump upper support 3, a top cover 4, a bottom cover 5, and a motor 6 to a compressor shell 1, This laser welding device is the prior art, and is a common laser welding machine circulating on the market. The laser welding device includes a welding head, a gathering lens arranged at the welding head, and the welding method of the compressor shell pump and the motor includes the following steps:

[0035] Step A, laser welding is used to weld the compressor pump cylinder 2 and the pump upper support 3 to the compressor shell 1;

[0036] Step A1, place the compressor pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com