Disc type part numerical control turning processing dimension on-line measurement device

A technology for disc parts and measuring devices, applied in metal processing equipment, measuring/indicating equipment, metal processing machinery parts, etc. Reasonable design and the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

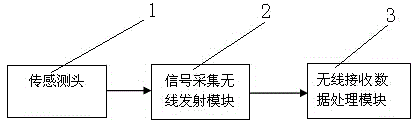

[0022] The on-line measuring device for the machining dimensions of disc parts by numerical control turning pins in this embodiment includes a device for aligning discs

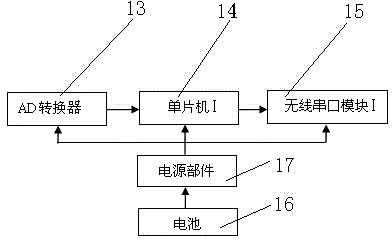

[0023] The sensing head 1 for dimension measurement of similar parts, the signal acquisition wireless transmitting module 2 for collecting and transmitting the data measured by the sensing head 1, and the wireless receiving data processing module 3 for receiving data;

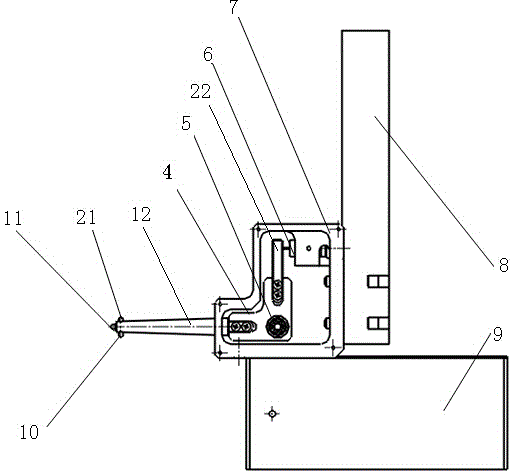

[0024] Sensing head 1 comprises shell 7 that is installed on the connecting rod 8 and the rotating shaft 5 that is arranged in shell 7, swing lever 4, displacement sensor 6, wherein, swing lever 4 is installed on the rotating shaft 5 and can swing around rotating shaft 5, One end of the swing lever 4 is pressed on the moving shaft of the displacement sensor 6, the other end of the swing lever 4 is located outside the shell 7, and a measuring device is installed at the end of the swing lever 4 outside the shell 7, and the swing lever 4 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com