Hot-melting and cold-pressing welding machine and welding method thereof

A welding machine and hot-melt technology, which is applied in the field of hot-melt cold-press welding machine and its welding, can solve the problem of insufficient welding of hot riveting welding machine, long welding cycle of hot riveting welding machine, offset of welding spot of hot riveting welding machine, etc. Solve the problem, achieve the effect of shortening the welding cycle, good welding effect and increasing the heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

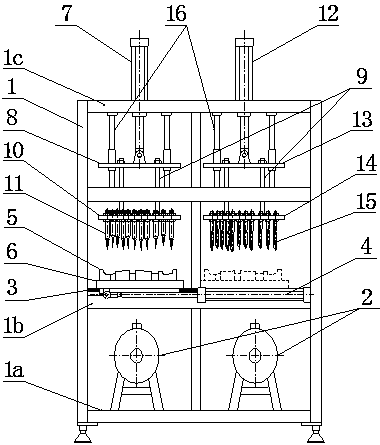

[0016] like figure 1 As shown: the welding machine has a frame 1, and the frame 1 has three decks, two gas storage tanks 2 are installed on the first deck 1a; the second deck 1b is located above the first deck 1a , a workpiece positioning mechanism, a guide rail 3 carrying the workpiece positioning mechanism, and a station drive cylinder 4 that drives the translation of the workpiece positioning mechanism are installed on the platen 1b; the third layer of platen 1c is located above the second layer of platen 1b, and the platen 1c is provided with a lift-type hot-melt mechanism and a lift-type cold-press mechanism in sequence along the translation direction of the workpiece positioning mechanism.

[0017] The workpiece positioning mechanism described above is used to place the bottom mold 5 of the workpiece and the bottom mold conversion plate 6 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com