Automobile front suspension lower swing arm assembly

A front suspension and hem technology, applied in the field of auto parts, can solve the problems of processing man-hours, heavy product quality, and large number of parts, and achieve the effects of improving comfort, improving overall strength, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

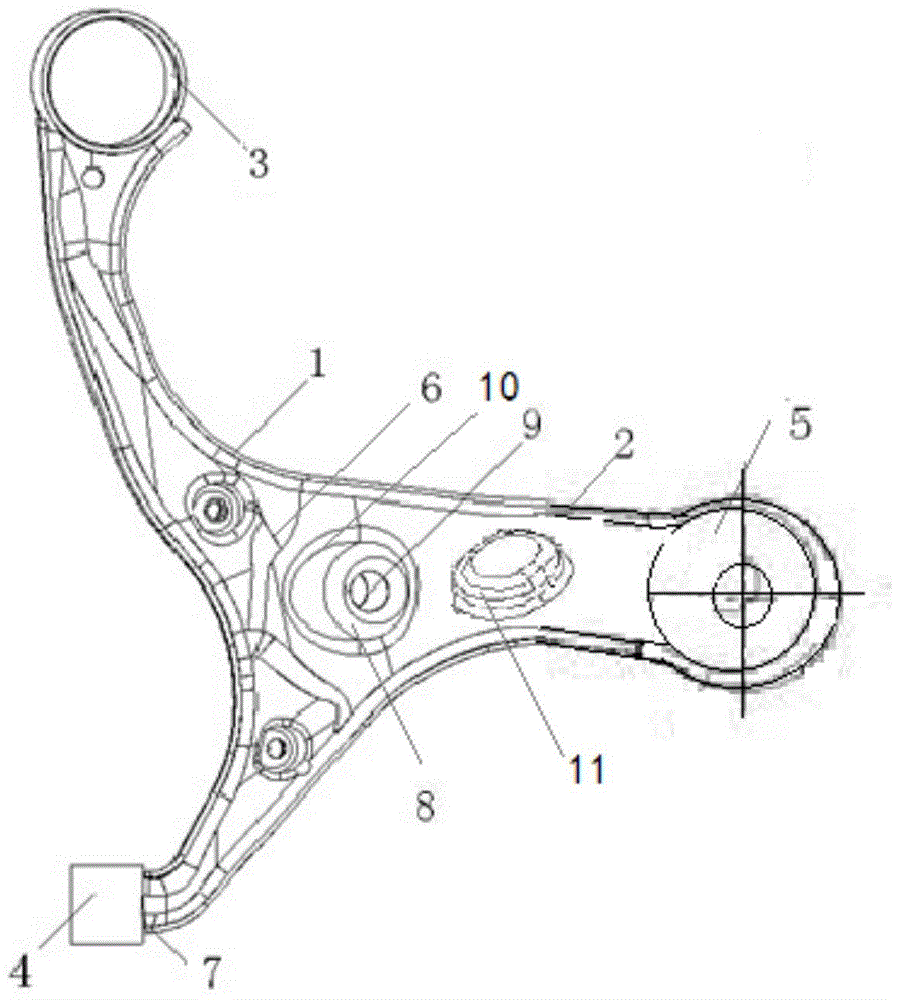

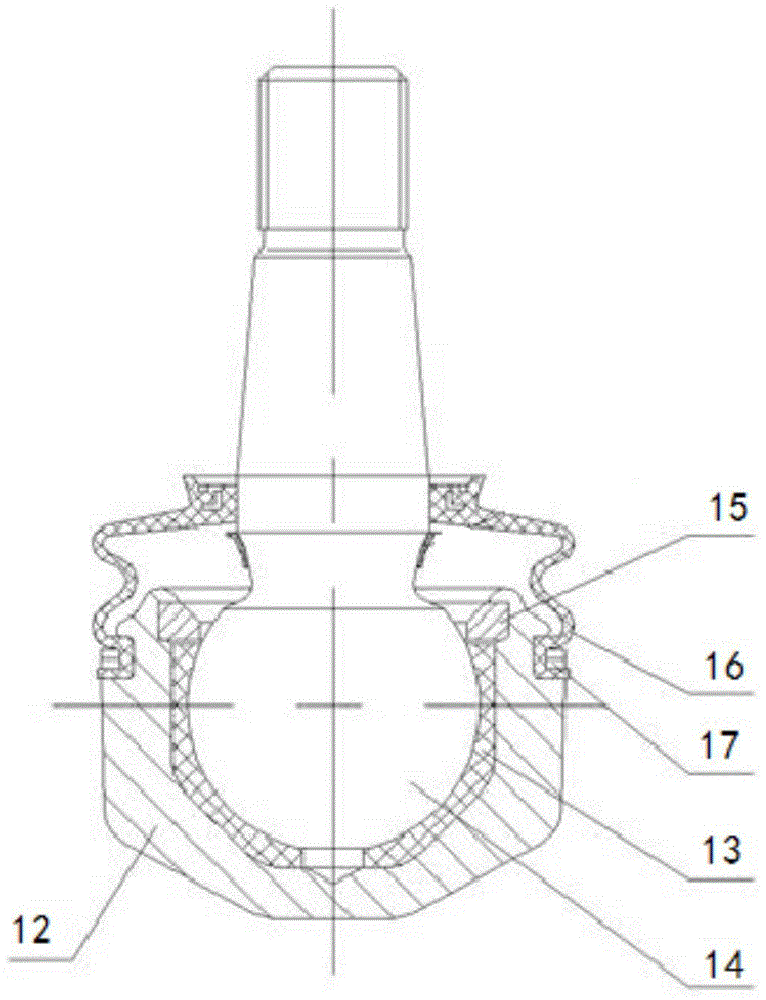

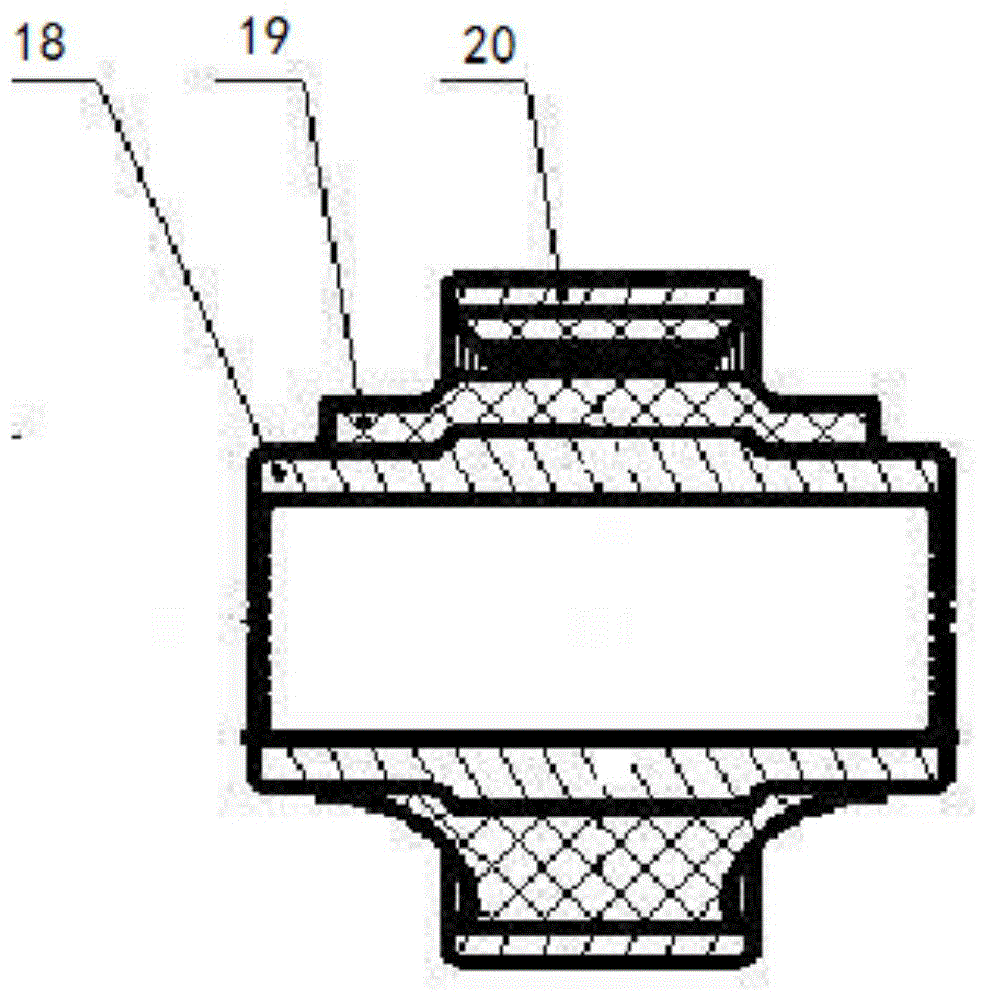

[0017] see Figure 1-3 , a lower swing arm assembly for the front suspension of an automobile, comprising a lower swing arm upper body 1, a lower swing arm lower body 2, an upper bushing 3, a lower bushing 4 and a ball head assembly 5, and the lower swing arm lower body 2 has a section of U shape, the U-shaped structure of the lower body 2 of the lower swing arm is easy to form, the U-shaped structure of the lower body 2 of the lower swing arm is provided with reinforcing ribs 6, and the two sides of the U-shaped opening of the lower body 2 of the lower swing arm are respectively provided with flanging 7, the lower swing arm The upper body 1 is a flat piece of equal thickness, and the thickness of the upper body 1 of the lower swing arm is uniform, so that the force is balanced everywhere, which is convenient for stamping and forming. The upper bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com