Automatic on-line pipe bundling device and method

An automatic bundling and pipe technology, which is applied in automatic control of packaging, parts of bundling machinery, packaging, etc., can solve problems such as inability to guarantee accuracy and complex structure, and achieve the goal of improving production efficiency, simple and compact structure, and reducing production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The first embodiment of the online automatic binding device for pipes of the present invention includes a frame on which a pipe collecting unit, a pipe temporary storage unit, a pipe taking and counting unit, a pipe sorting unit and a pipe conveying unit are arranged, and the first part of the pipe collecting unit is The outlet is connected to the pipeline temporary storage unit. The pipeline temporary storage unit is provided with a second outlet for only one pipeline to pass through. The second outlet is connected to the pipe taking and counting unit. The number of pipelines, the pipeline conveying unit is arranged below the pipeline finishing unit.

[0033] The online automatic bundling device for pipes can automatically complete the automatic bundling process of pipe collection and detection, temporary storage of pipes, sorting and sorting of pipes, lifting and counting of pipes, leveling and clamping of pipes, winding and bundling of pipes, and online bundling outpu...

Embodiment 2

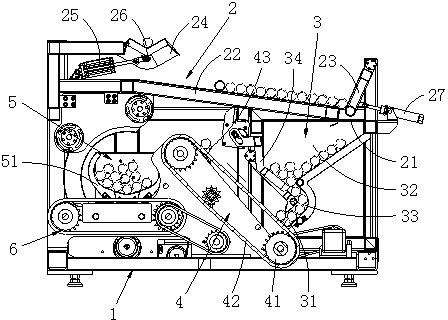

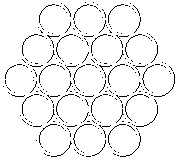

[0035] Such as Figure 1 to Figure 2 Shown is the second embodiment of the pipe online automatic binding device of the present invention, including a frame 1, on which a pipe collection unit 2, a pipe temporary storage unit 3, a pipe taking counting unit 4, a pipe sorting unit 5 and pipe Delivery unit 6. Wherein, the pipeline collection unit 2 is provided with a first outlet 21, and the pipeline temporary storage unit 3 is provided with a second outlet 31 through which only one pipeline passes.

[0036] In this embodiment, the pipeline collection unit 2 includes a collection sloping plate 22, the beginning of the collection swash plate 22 is provided with a pipe connection mechanism, and the end is connected to the first outlet 21. The movable flashboard 23 of.

[0037] Among them, such as figure 1 As shown, the takeover mechanism includes an overturning guide groove 24 fixed on the frame 1 and an overturning cylinder 25. The overturning guide groove 24 is used to accept th...

Embodiment 3

[0047] This embodiment is a pipe bundling method using the online automatic bundling device of the above embodiment, including the following steps:

[0048] S1. The pipeline collection unit collects the pipelines to be sorted and bundled, and at this time, detects the pipelines;

[0049] S2. The pipeline after passing the inspection enters the pipeline temporary storage unit from the first outlet, and at this time, the pipeline is arranged and sorted to the second outlet;

[0050] S3. The pipelines are sent out from the second outlet and transported to the pipeline sorting unit one by one through the tube taking and counting unit;

[0051] S4. Pipes are clamped, pipe ends leveled and bundled in a certain amount in the pipe finishing unit;

[0052] S5. The bundled pipeline is output from the pipeline delivery unit.

[0053] In actual use and operation, the device can be integrated with the finished product frame of the extruder production line, that is, the pipe collection un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com