Hoisting device for fine bismuth cast ingot

A technology of casting ingots and bismuth ingots, which is applied in the field of non-ferrous metal smelting equipment, which can solve the problems of threats to the personal safety of operators, consumption of physical strength of operators, weight of bismuth ingots, etc., and achieve the effect of avoiding property loss or personal injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The detailed structure of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

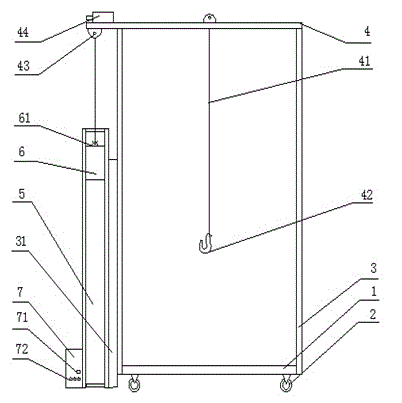

[0017] Such as figure 1 Shown: a lifting device for refined bismuth ingots, including a base 1, a universal wheel 2 located on the lower side of the base 1, a support column 3 located at both ends of the base 1, a beam 4 spanning the support column 3, and a The lifting platform 5 on one side of the support column 3 and the lifting piece for lifting bismuth ingots are installed on the beam 4; the inside of the lifting platform 5 is equipped with a buffer mechanism 6 that can move up and down along the lifting platform 5, and the buffer mechanism 6 is controlled by the lifting piece. .

[0018] Specifically, the lifting member includes a rope 41 and a hook 42 arranged on the beam 4 and a gear transmission assembly located at one end of the beam 4; the gear transmission assembly includes a reduction gear set 43 with an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com