A kind of process method of preparing rare earth sulfur oxide with alkali metal chloride

A technology of rare earth sulfur oxides and alkali metal chlorides, which is applied in the direction of rare earth metal compounds, rare earth metal sulfides, chemical instruments and methods, etc., can solve the problems of large particles and reduced luminescent performance, so as to reduce production costs and reduce Effect of Particle Range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

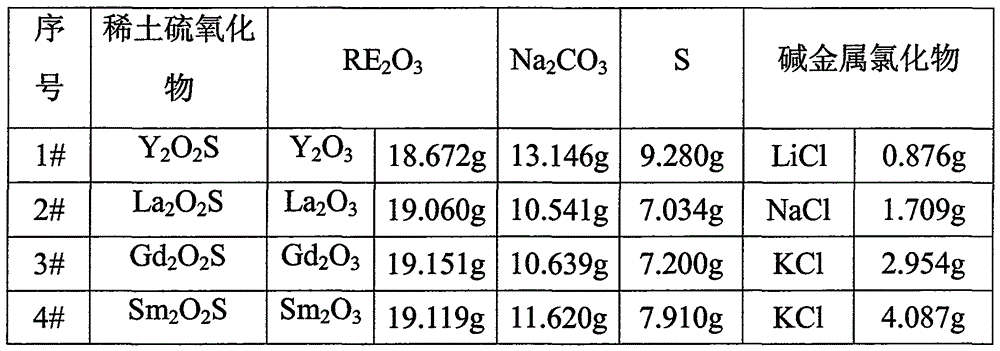

[0019] 原料组成如表1中1 # 所示,具体制备方法包括下列步骤:

[0020] ①按重量称取18.672g Y 2 o 3 、13.146g Na 2 CO 3 (mol(Na 2 CO 3 ):mol(Y 2 o 3 )=1.5)、9.280g升华硫(mol(升华硫):mol(Y 2 o 3 )=3.5)和0.876gLiCl(mol(LiCl):mol(Y 2 o 3 )=0.25),将称好的物料混合均匀;

[0021] ②将混合均匀的物料装入内外均带盖的套坩埚中,在两坩埚的间隙填充耐高温粉末并压实;

[0022] ③将装有混合料的坩埚以升温速率2℃ / min升温到300℃,并保温1h,然后以升温速率3℃ / min升温至1100℃,烧结3h,然后随炉降温至室温;

[0023] ④烧结后的产物用热水洗涤并搅拌,抽滤;

[0024] ⑤将洗涤后的产物放入恒温鼓风干燥箱中烘干,得到稀土硫氧化物。

[0025] 对该稀土硫氧化物的测试结果如下:

[0026] 将过程⑤中烘干后的粉料用X射线衍射仪(XRD,D / Max2500)进行相组成分析,结果显示主要衍射峰的位置都与六方Y 2 o 2 S相对应,并且没有其他物质相的峰存在;用扫描电子显微镜(SEM,JEOL-6310)进行颗粒形貌分析,并采用软件进行颗粒尺寸统计,结果显示颗粒分布均匀,平均颗粒尺寸为3μm。

Embodiment 2

[0028] ①按重量称取19.060g La 2 o 3 、10.541g Na 2 CO 3 (mol(Na 2 CO 3 ):mol(La 2 o 3 )=1.7)、7.034g升华硫(mol(升华硫):mol(La 2 o 3 )=3.75)和1.709gNaCl(mol(NaCl):mol(La 2 o 3 )=0.5),将称好的物料混合均匀;

[0029] ②将混合均匀的物料装入内外均带盖的套坩埚中,在两坩埚的间隙填充耐高温粉末并压实;

[0030] ③将装有混合料的坩埚以升温速率2.5℃ / min升温到330℃,并保温1.5h,然后以升温速率3.5℃ / min升温至1150℃,烧结4h,然后随炉降温至室温;

[0031] ④烧结后的产物用热水洗涤并搅拌,抽滤;

[0032] ⑤将洗涤后的产物放入恒温鼓风干燥箱中烘干,得到稀土硫氧化物。

[0033] 对该稀土硫氧化物的测试结果如下:

[0034] 将过程⑤中烘干后的粉料用X射线衍射仪(XRD,D / Max2500)进行相组成分析,结果显示主要衍射峰的位置都与六方La 2 o 2S相对应,并且没有其他物质相的峰存在;用扫描电子显微镜(SEM,JEOL-6310)进行颗粒形貌分析,并采用软件进行颗粒尺寸统计,结果显示颗粒分布均匀,平均颗粒尺寸为2.3μm。

Embodiment 3

[0036] 组成如表1中3 # 所示,具体制备方法包括下列步骤:

[0037] ①按重量称取19.151gGd 2 o 3 、10.639g Na 2 CO 3 (mol(Na 2 CO 3 ):mol(Gd 2 o 3 )=1.9)、7.200g升华硫(mol(升华硫):mol(Gd 2 o 3 )=4.25)和2.954gKCl(mol(KCl):mol(Gd 2 o 3 )=0.75),将称好的物料混合均匀;

[0038] ②将混合均匀的物料装入内外均带盖的套坩埚中,在两坩埚的间隙填充耐高温粉末并压实;

[0039] ③将装有混合料的坩埚以升温速率3℃ / min升温到360℃,并保温2h,然后以升温速率4℃ / min升温至1200℃,烧结5h,然后随炉降温至室温;

[0040] ④烧结后的产物用热水洗涤并搅拌,抽滤;

[0041] ⑤将洗涤后的产物放入恒温鼓风干燥箱中烘干,得到稀土硫氧化物。

[0042] 对该稀土硫氧化物的测试结果如下:

[0043] 将过程⑤中烘干后的粉料用X射线衍射仪(XRD,D / Max2500)进行相组成分析,结果显示主要衍射峰的位置都与六方Gd 2 o 2 S相对应,并且没有其他物质相的峰存在;用扫描电子显微镜(SEM,JEOL-6310)进行颗粒形貌分析,并采用软件进行颗粒尺寸统计,结果显示颗粒分布均匀,平均颗粒尺寸为1.8μm。

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com