Photo-curing equipment

A light-curing and equipment technology, applied in the field of light-curing molding equipment, can solve problems such as inability to cure efficiently, achieve the effect of simple and easy replacement of light sources, and achieve curing and high-efficiency curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the accompanying drawings and specific implementation cases.

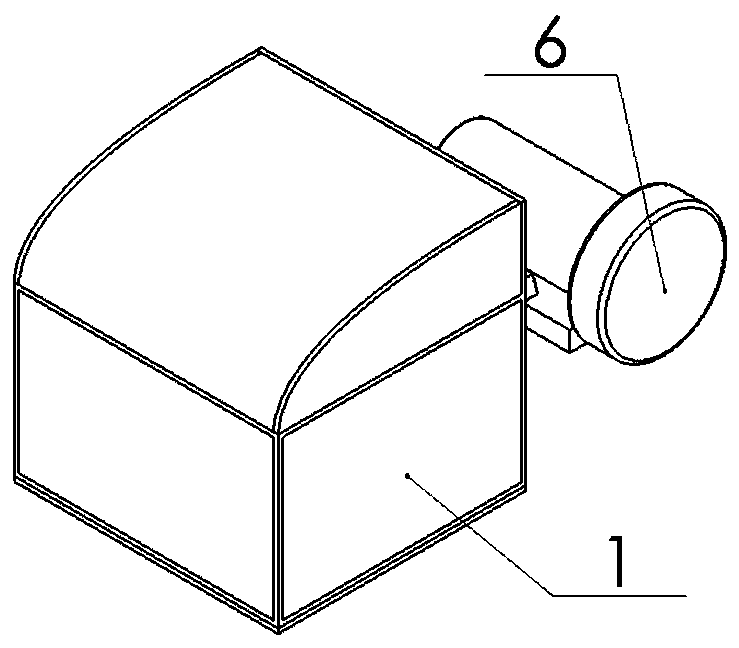

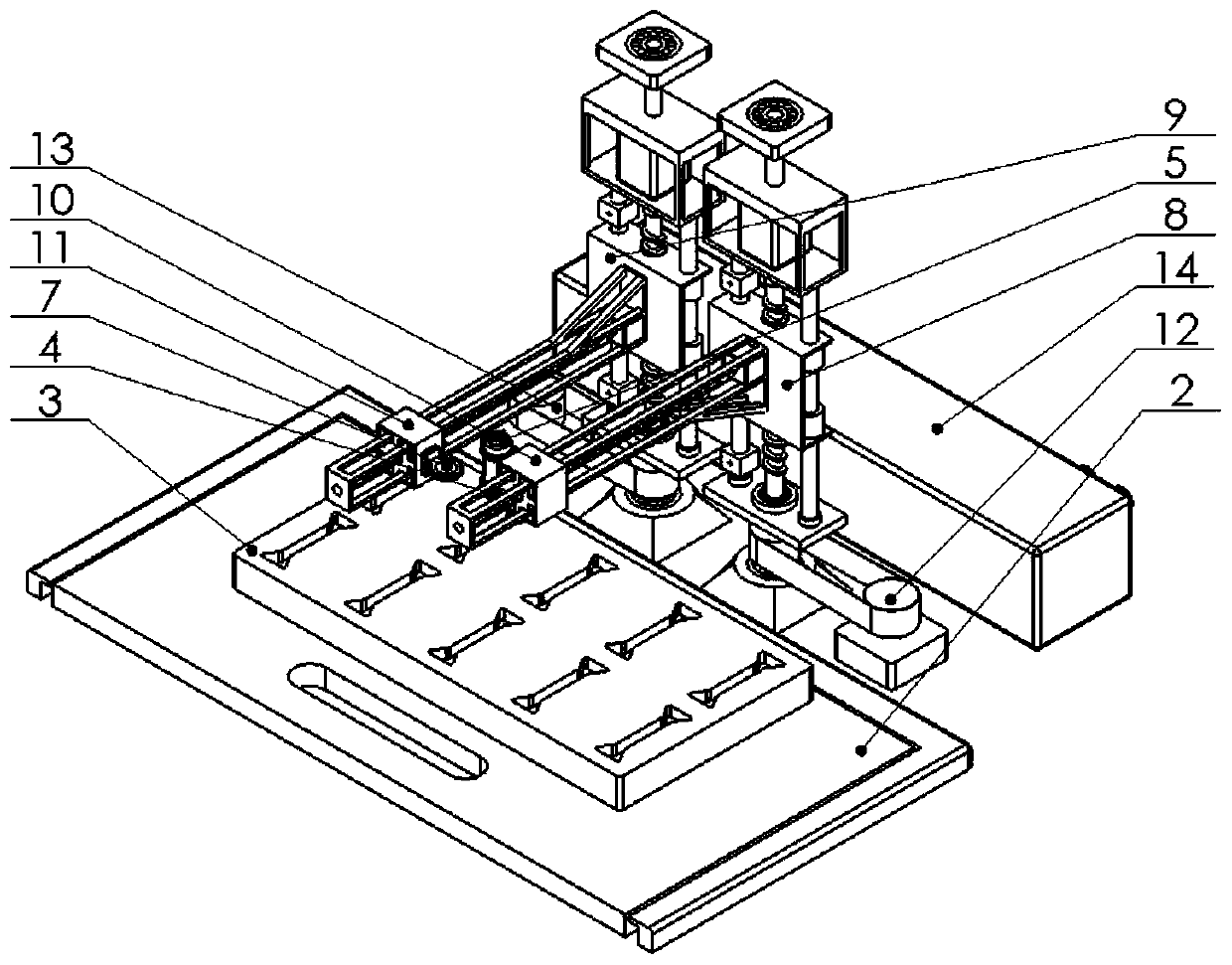

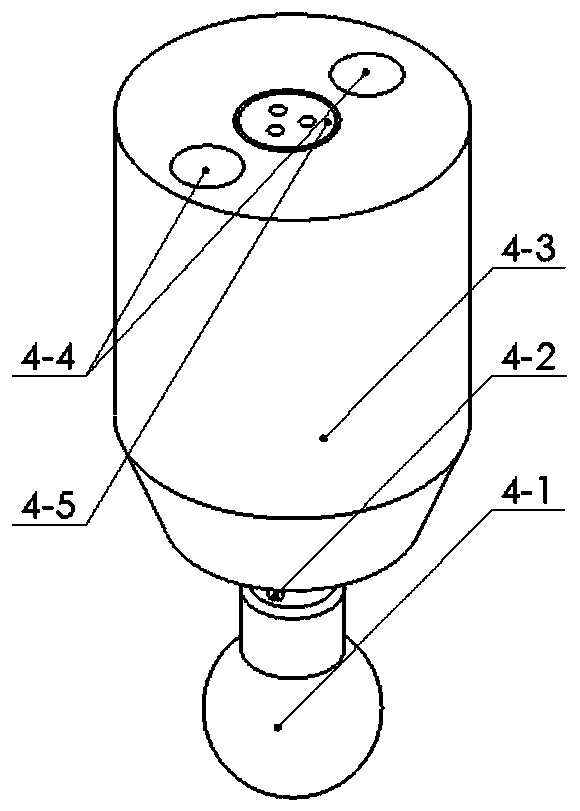

[0035] like figure 1 and figure 2 As shown, a light curing device of the present invention includes a light hood 1 with an openable front side panel, a stage 2 placed on the inner bottom plate of the light hood 1, a mold or a trough 3 hovering on the stage 2 , the light source 4 that is fixed above the mold or the material tank 3 to provide light of a specific wavelength required for curing the photocurable material, and the light source conversion module 5 that is connected to the light source 4 to realize the conversion between multiple light sources of specific wavelengths, and realizes the spatial position adjustment of the light source 4. The light source lifting module 8 , the light source translation module 10 and the light source rotation module 12 , the light intensity meter 7 hovering above the mold or the material trough 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com