Paddle suspension type pulp electrolytic bath

A slurry electrolytic cell and suspension technology, which is applied to cells and other directions, can solve the problems of high energy consumption, unsmooth electrolysis, slow dissolution of mineral powder, etc., and achieve the effect of broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

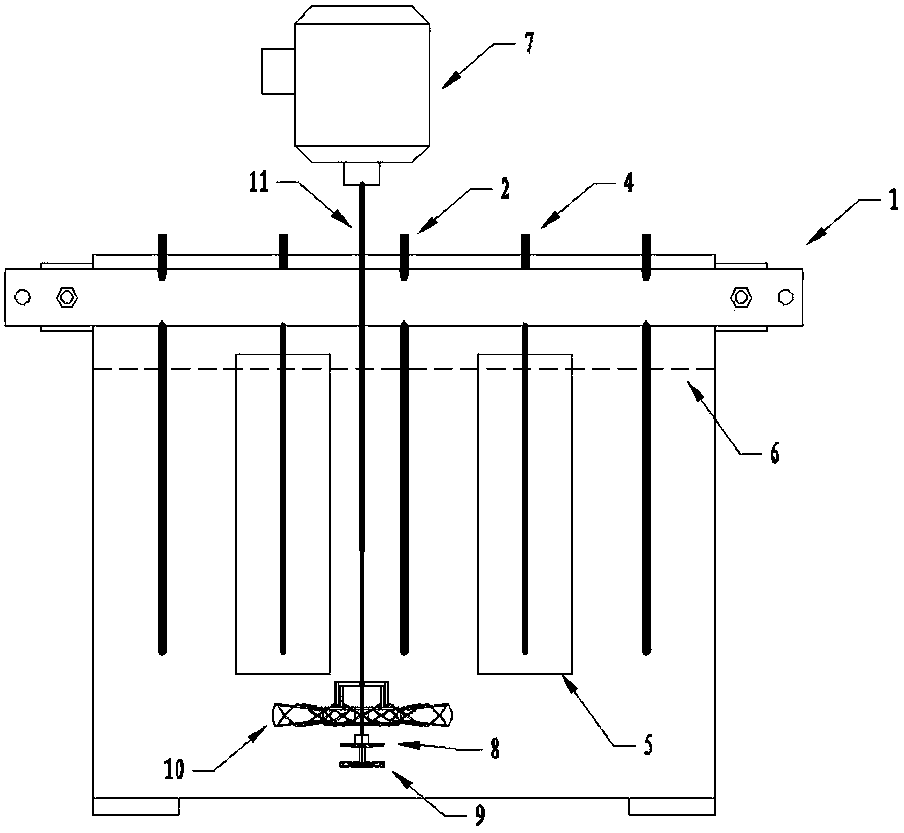

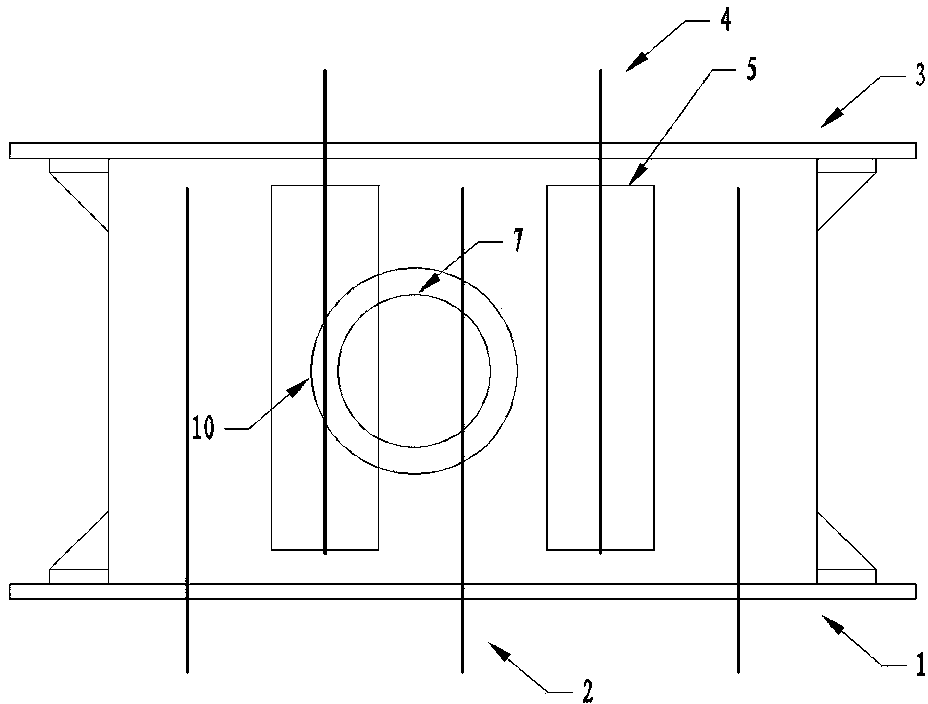

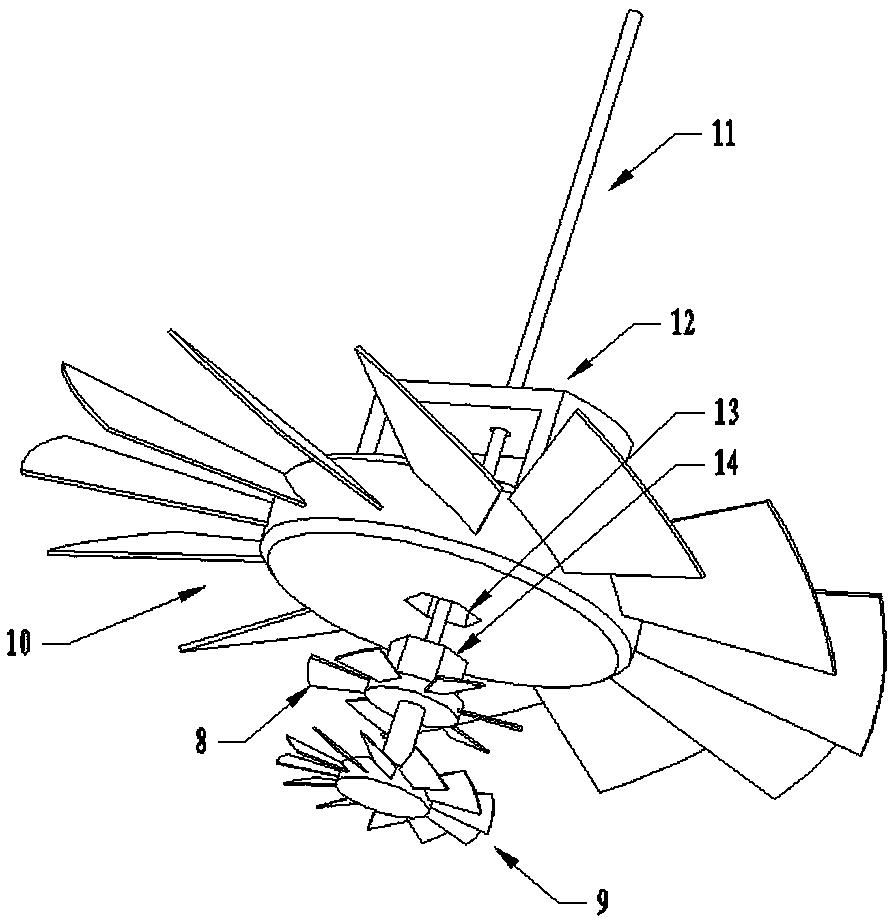

[0028] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0029] Such as figure 1 , figure 2 , image 3 with Figure 4 The paddle-suspended slurry electrolytic cell shown includes positive copper strips, anode plates, negative copper strips, cathode plates, electrolytic diaphragms and agitators. Plates 2 and 4 and positive and negative copper strips 1 and 3 are V-shaped. Connect; the agitator is composed of a stirring power 7, a stirring shaft 11 and three layers of paddles in the upper 10, middle 8, and lower 9, the upper paddle 10 is a floating paddle that moves freely up and down, and the middle and lower paddles 8, 9 are fixed on the agitating shaft 11 On, the middle layer blade 8 is a dihedral type, and the upper floating blade 10 can be integrated with the middle layer anhedral blade 8 under the action of gravity; the upward water flow generated by the middle layer dihedral blade 8 high-speed operation can make the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com