Reinforcement connection assembly and concrete reinforcement connection system and construction method thereof

A technology for connecting components and concrete, applied in the direction of building structure, construction, etc., can solve the problems of increasing the construction period of the house, long construction period, etc., and achieve the effect of simple connection structure and connection system, fast on-site assembly, and fast preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

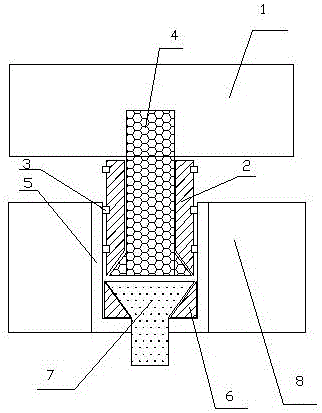

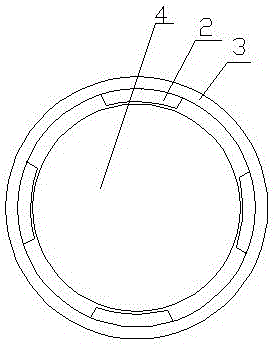

[0026] Such as Figure 1-Figure 2 shown.

[0027] The steel bar connection assembly includes the connecting steel bar 7, which is a cylindrical steel bar. In special cases, other shapes of steel bars, such as rectangular steel bars or other polygonal or semicircular steel bars, can be used to expand the above-mentioned connecting steel bar 7 in the workshop. The rough process makes the connecting steel bar 7 include an extension part and an expansion section part, and the expansion section part is a cylindrical column, and one end of the extension part is integrally connected with the small-diameter end face of the circular platform column, and the sleeve 5 is also included, which is processed in the workshop, so that the sleeve The barrel 5 has an open end and a closed end, the extension of the connecting steel bar 7 runs through the closed end of the sleeve 5, so that the expansion section of the connecting steel bar 7 is located in the sleeve 5, and also includes a connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com