Test system of propulsive water-jet pump based on echoic environment and test method thereof

A technology of water jet propulsion and noise testing, which is applied in pump testing, liquid variable displacement machinery, machine/engine, etc. It can solve the problems of poor test economy, difficult flow measurement, immature water jet propulsion pump noise technology, etc. Achieve the effect of strong operability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

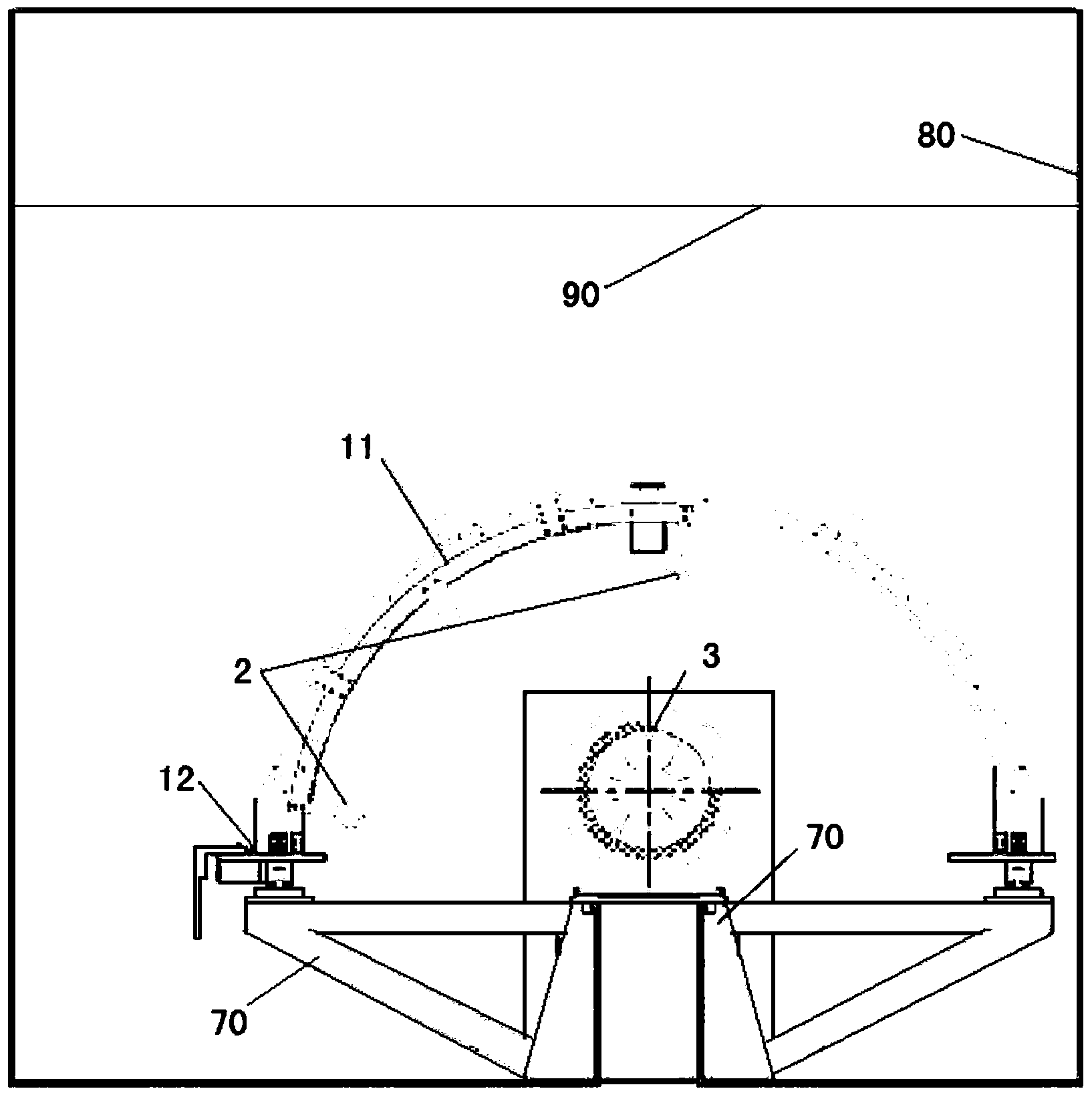

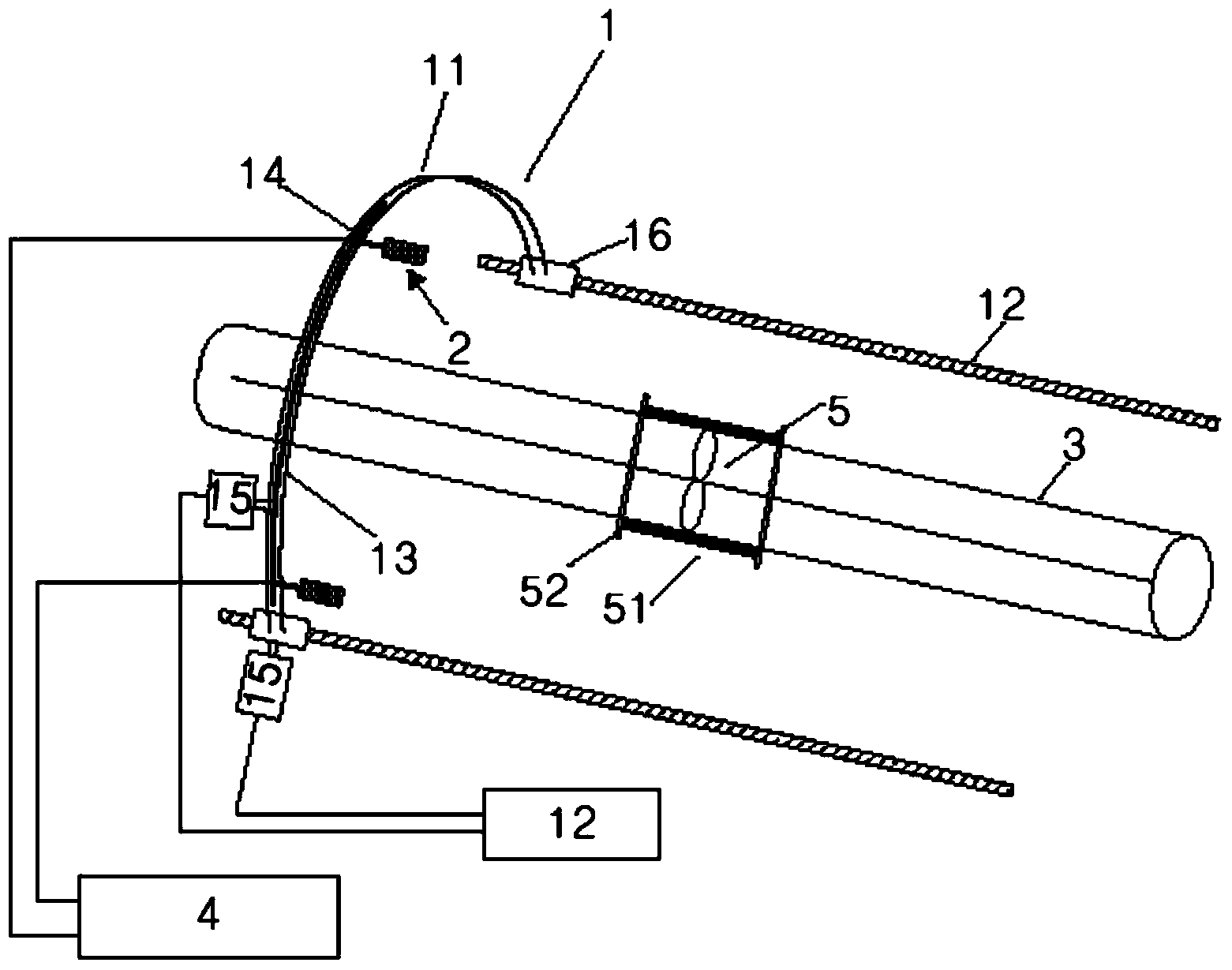

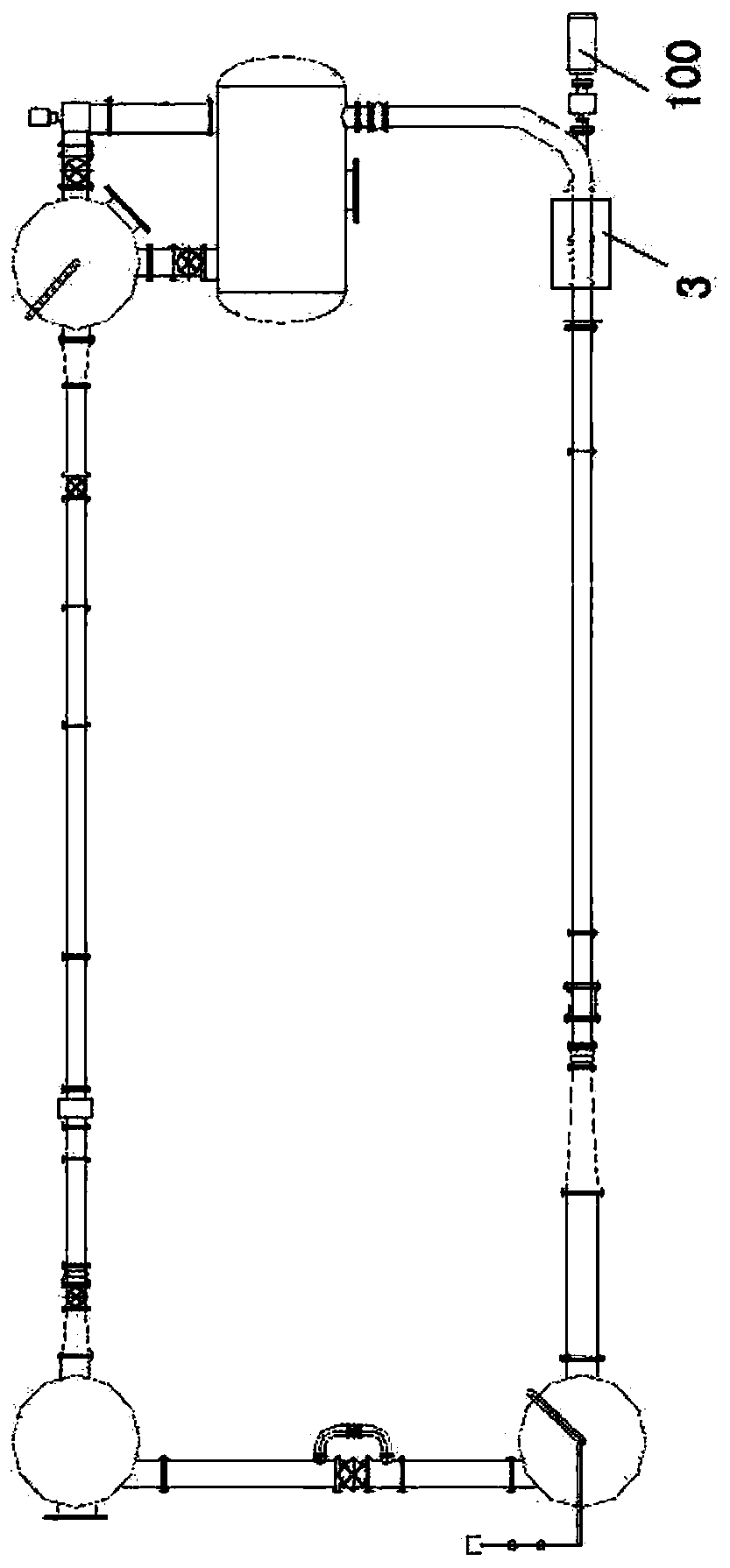

[0042] Such as figure 1 , figure 2 As shown, a water jet propulsion pump noise test system based on a non-anechoic environment, including a mechanical scanning system 1, several vector hydrophones 2, a closed circulation system of a water jet propulsion pump comprehensive performance test bench, and a non-anechoic water pool 80 , data acquisition and analysis system 4 and water jet propulsion pump model 5;

[0043] The mechanical scanning system 1 includes a mechanical scanning device 11 and a control system 12. The mechanical scanning device 11 moves along the axial direction of the pipeline of the test section of the closed circulation system of the water jet propulsion pump comprehensive performance test bench, and the control system 12 controls the movement of the mechanical scanning devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com