Mine pump automatic unloading hydraulic control valve assembly

An automatic unloading, hydraulic control valve technology, applied to the components of the pumping device for elastic fluids, safety valves, balance valves, etc., can solve the problems of shortened service life of motors and pumps, waste of energy, and temperature rise. , to achieve a wide range of applications, easy installation, light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

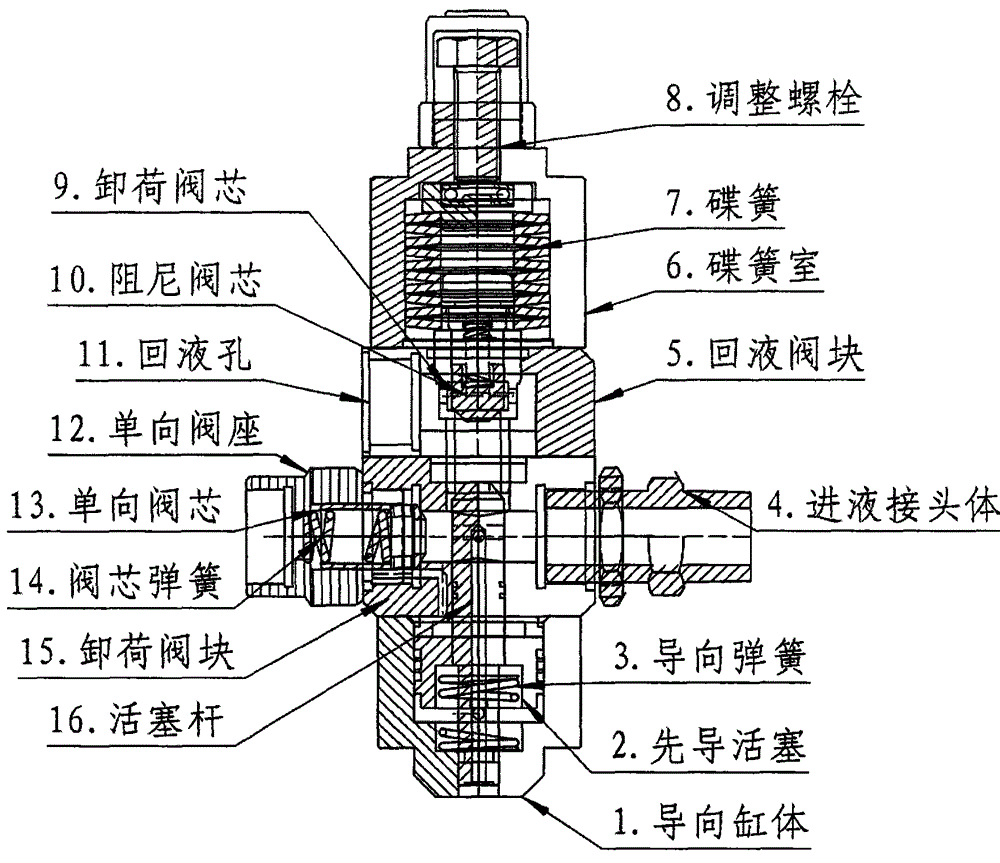

[0016] As shown in Figure 1, the mine pump automatic unloading hydraulic control valve assembly according to the embodiment of the present invention includes: (1) guide cylinder, (2) pilot piston, (3) guide spring, (4) liquid inlet Joint body, (5) liquid return valve block, (6) disc spring chamber, (7) disc spring, (8) adjusting bolt, (9) unloading spool, (10) damping spool, (11) liquid return Hole, (12) one-way valve seat, (13) one-way valve core, (14) spool spring, (15) unloading valve block, (16) piston rod; It is characterized in that: described guide spring (3) and the pilot piston (2) are sequentially installed in the guide cylinder (1); the unloading valve core (9) and the damping valve core (10) are installed in the unloading valve block (15); the one-way valve seat (12), one-way spool (13) and spool spring (14) are installed on the side of the unloading valve block (15); the adjustment bolt (8), disc spring (7) is installed in the disc spring chamber (6) Middle; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com