Safety valve liquid return system and integrated safety valve liquid return valve block

A safety valve and liquid return valve technology, which is applied to the safety of fluid pressure actuation systems, fluid pressure actuation devices, mining equipment, etc. The effect of convenient maintenance, realization of system liquid return circulation, and high degree of design integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in terms of specific embodiments in conjunction with the accompanying drawings.

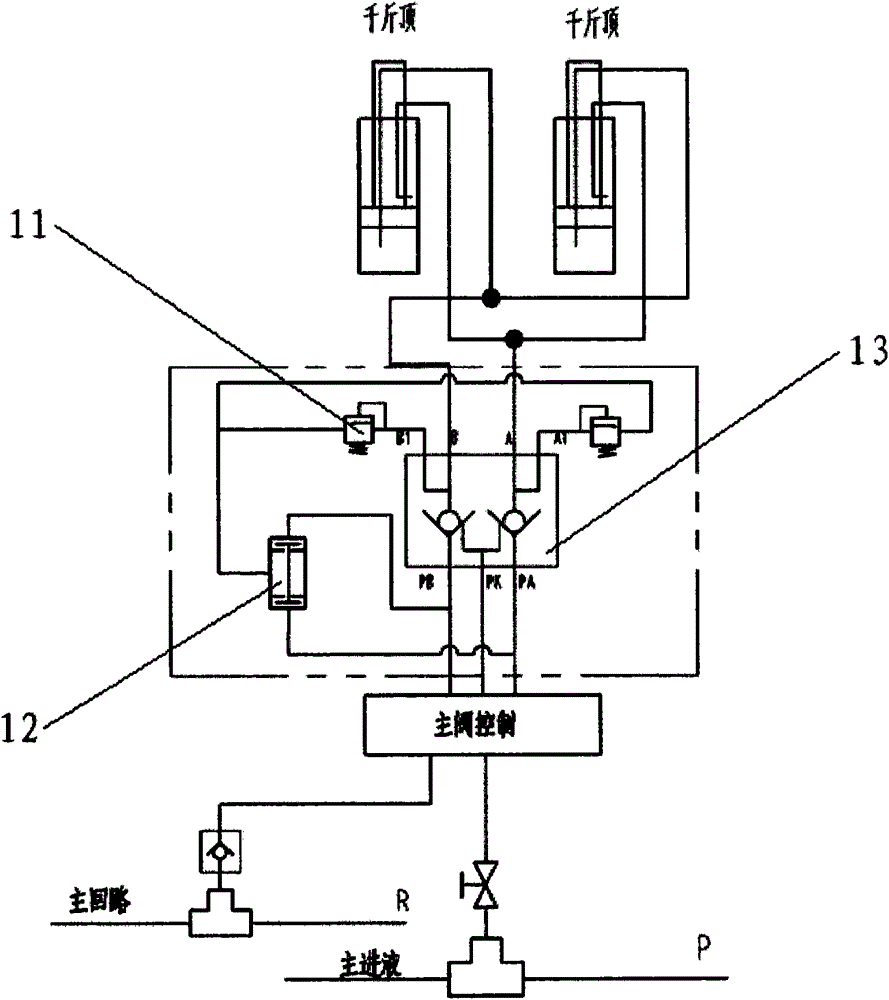

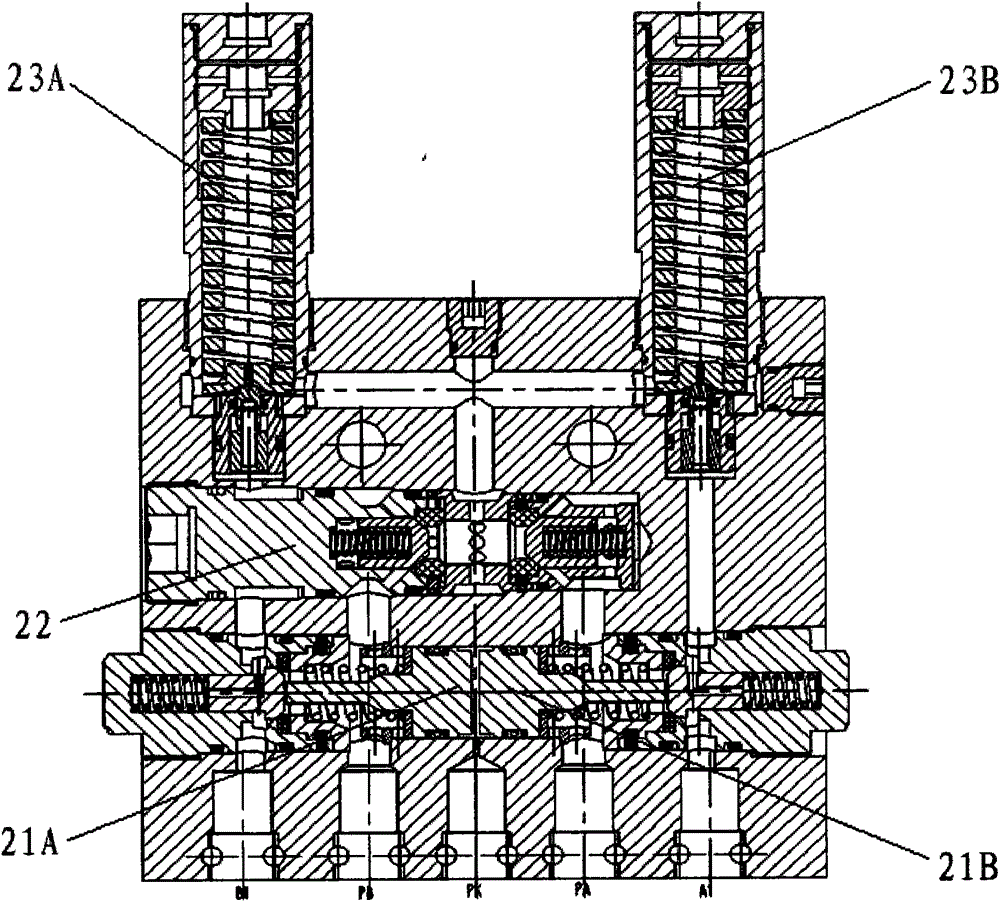

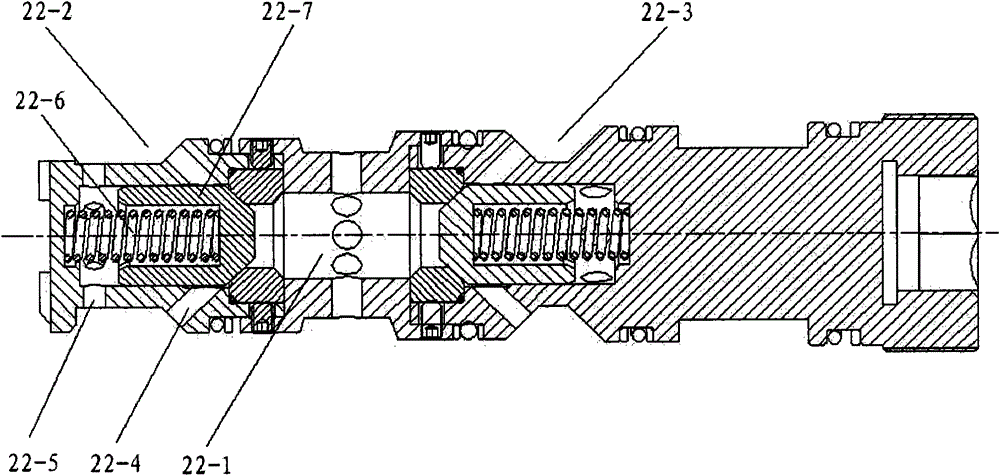

[0027] See attached figure 1 , which describes the system principle of the safety valve liquid return system according to the present invention. The safety valve liquid return system is used for the safety valve liquid return control of the coal mine underground hydraulic system, as attached figure 1 As shown in the part in the dotted line box, it includes two safety valves, two-way hydraulic control two-way lock and three-way logic valve. The liquid outlets of the two safety valves are respectively in fluid communication with the liquid passage chamber of the three-way logic valve; the three-way logic valve includes A chamber and B chamber, and the A chamber is in fluid communication with or fluidly blocked from the liquid passage chamber through the movable plug component A , chamber B is in fluid communication or fluid is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com