Shale adsorbed gas content analysis system

A technology for analyzing system and adsorbing gas, applied in the system field, can solve the problems of large error of shale gas, imprecise design of adsorption conditions, large error in determination of shale gas composition content, etc., and achieve the effect of convenient processing and utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

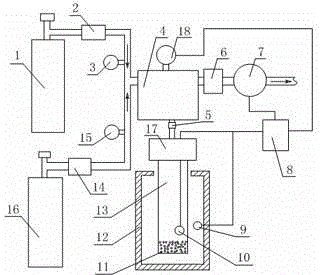

[0015] Such as figure 1 As shown, the shale gas adsorption gas content analysis system includes a hollow heating furnace 12, the cavity of the heating furnace 12 is provided with a sample tank 13 with a hollow inside and an open top, and the cavity of the sample tank 13 is provided with Adsorbent 11, the top of the sample tank 13 is arranged above the heating furnace 12, the opening of the sample tank 13 is provided with a sealing sleeve 17, and the sealing sleeve 17 can completely close the opening, the sample tank 13 is provided with a temperature measuring thermocouple 10, measuring The bottom end of the thermocouple 10 is set above the adsorbent 11 and close to the adsorbent 11, and the heating furnace 12 is provided with a temperature control thermocouple 9, and the temperature control thermocouple 9 is arranged outside the sample tank 13, and the temperature measuring thermocouple 10 is connected to There is a control box 8, and the control box 8 is arranged outside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com