Method for integrally automatically generating pipeline designs

An automatic generation and pipeline design technology, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problems affecting the progress and quality of the project, low design efficiency, prone to errors, etc., to improve design quality, improve efficiency, reduce The effect of error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

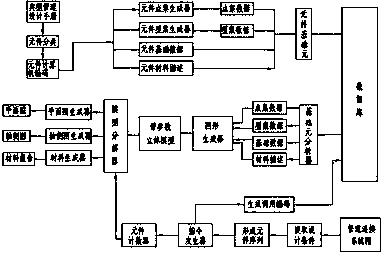

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, component coding:

[0025] Determine the coding rules: computer code the components in the typical piping design manual, and the coding is divided into seven parts:

[0026] The first part: name code, represented by 1 English letter, such as:

[0027] P stands for pipe; E stands for elbow; T stands for tee; R stands for size head and so on.

[0028] The second part: grade code, represented by design pressure or nominal pressure, the unit is MPa.

[0029] The third part: material category, represented by a capital English letter, such as |:

[0030] C: carbon steel; A: alloy steel; S: stainless steel.

[0031] The fourth part: material code, represented by 2 digits, there are more than 20 kinds of materials in total, such as: 11 is Q235-A material, 12 is 15CrMOG material, 13 is 20G material, 33 is A335P22 material.

[0032] The fifth part: type code, represented by two capital English letters:

[0033] S0: seamless outer diameter; SI: seamless inner di...

Embodiment 2

[0045] Embodiment 2, pipeline design:

[0046] Taking the design of a pipeline as an example, the pipeline includes elbows, size heads, tees, etc. The material selected is 15CrMOG, the pressure is 4.2MPa, the design temperature is 455 degrees, the pipeline passes through the size head, so there are two sizes of pipe diameters, DN400 and DN350. In the design, the elbows of the pipelines are all 90-degree elbows.

[0047] According to the pipeline wiring schematic diagram and the above design conditions, combined with the component coding rules, the execution command can automatically find out the component code to be called this time:

[0048] Pipes: P4.2A12SO400 and P4.2A12SO350.

[0049] P stands for pipe, 4.2 stands for pressure, A stands for alloy steel, 12 stands for material is 15CrMOG, SO stands for seamless steel pipe, 400 stands for nominal diameter.

[0050] Elbows: E4.2A12SO400A90 and E4.2A12SO350A90.

[0051] Tee: T4.2A12EO400X400A90.

[0052] Size head: R4.2A1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The way to | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com