Bracket and spacecraft cable network assembly method

A technology for cable nets and spacecraft, applied in circuits, electrical components, coupling devices, etc., can solve the problems of increasing difficulty in assembly and quality risks, and achieve the effects of improving process reliability, reducing difficulty, and simplifying processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

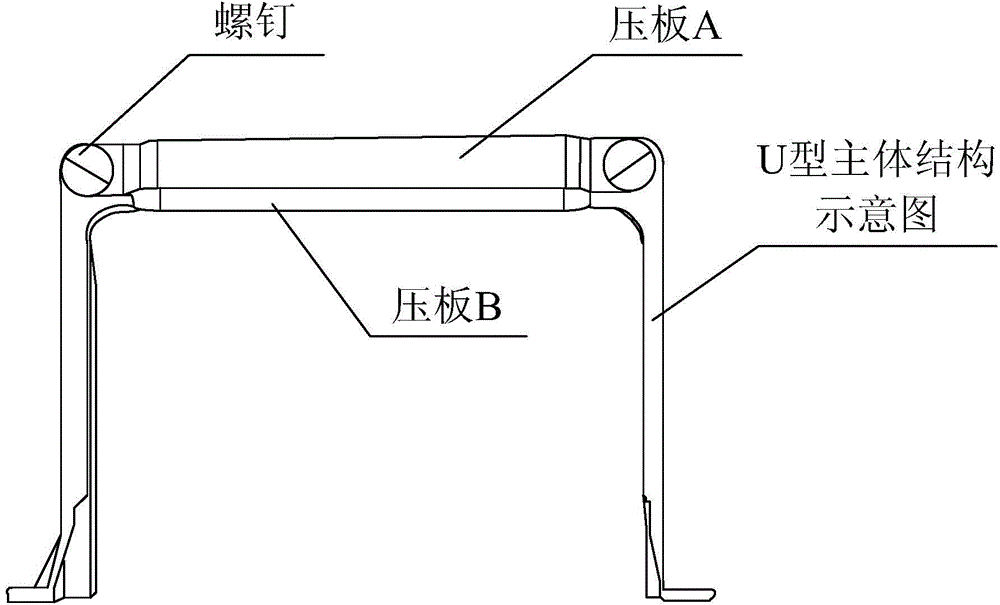

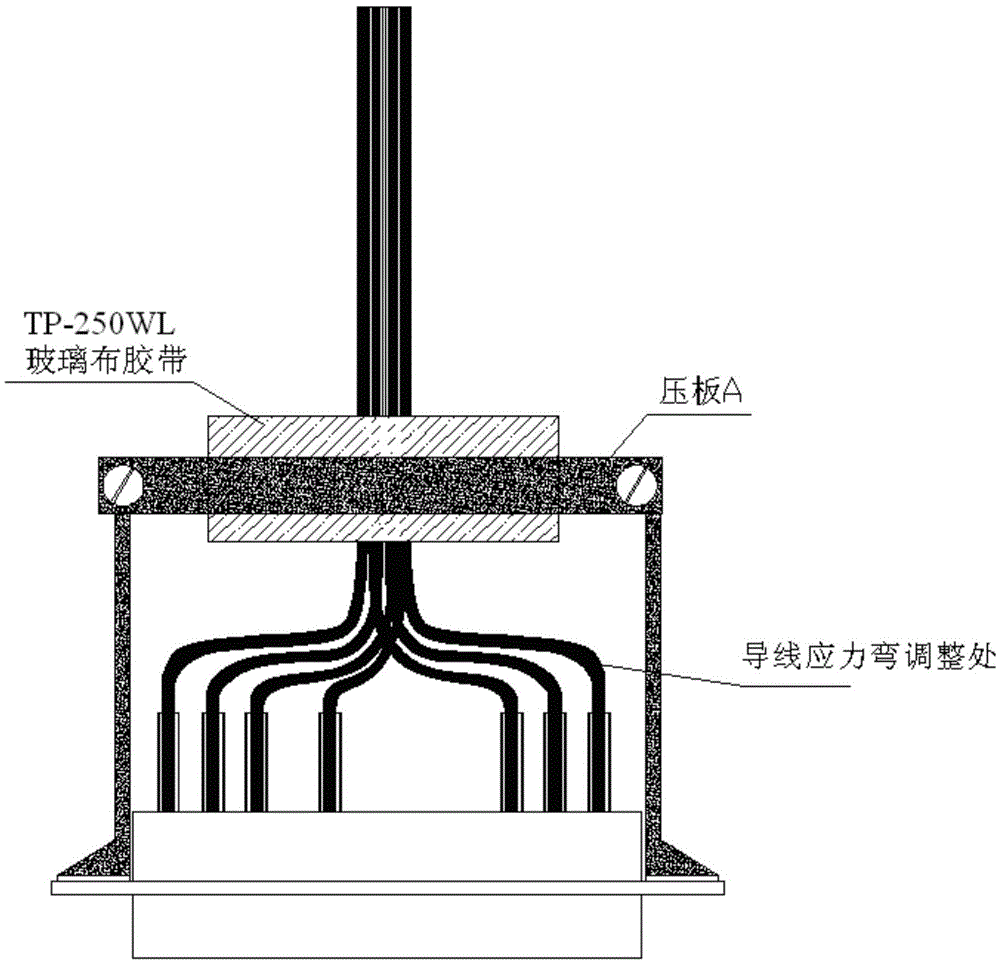

[0020] A support for a spacecraft cable network, such as figure 1 As shown, the bracket includes a U-shaped main structure and a pressing plate A; the U-shaped main structure includes supporting plates on both sides and a pressing plate B for connecting the supporting plates on both sides; there is a connecting hole at both ends of the pressing plate A, and the pressing plate There is a connection hole at both ends of B, the pressure plate A and the pressure plate B match, the screw is locked through the connection hole on the pressure plate A and the pressure plate B, after locking, the pressure plate A and the pressure plate B form a wire clamp, the pressure plate A and the pressure plate B There is a space between them for holding the cable harness, and the distance between the pressure plate A and the pressure plate B forms the height of the clamp; there is a lug on the top of the support plate on both sides, and there is a connecting hole on the lug. To lock with the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com