Optical member, adhesive composition and liquid crystal display device

A pressure-sensitive adhesive layer, optical element technology, applied in the direction of optical elements, adhesive types, ester copolymer adhesives, etc., can solve problems such as thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

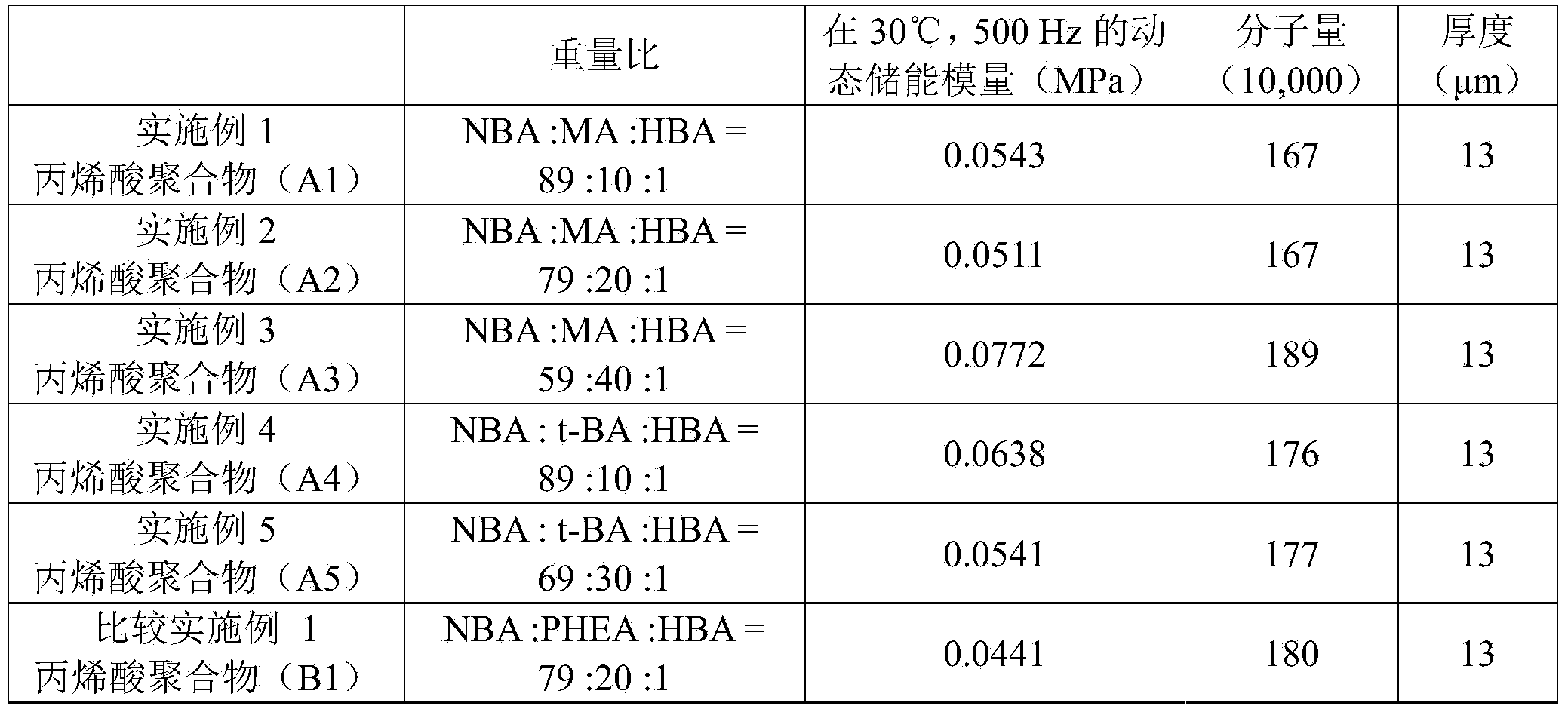

[0061] Preparation Example 1: Preparation of Acrylic Polymer (A1)

[0062] A monomer mixture consisting of 89 g n-butyl acrylate (BA), 10 g methyl acrylate (MA), and 1 g hydroxybutyl acrylate (HBA) was charged into a 1000 cc reaction vessel equipped with cooling for temperature control and refluxing nitrogen, then 100 g of ethyl acetate (EAc) was added as solvent. Afterwards, in order to remove oxygen, the mixture was flushed with nitrogen for 20 minutes and kept at 60°C. After the mixture was uniformly mixed, 0.03 g of azobisisobutyronitrile (AIBN) diluted in ethyl acetate at a concentration of 50% was added as an initiator to initiate the reaction. The mixture was reacted for 8 hours, thereby preparing an acrylic polymer having a weight average molecular weight of 1,790,000.

preparation Embodiment 2

[0063] Preparation Example 2: Preparation of Acrylic Polymer (A2)

[0064] Except for using a monomer mixture in which 79 g of n-butyl acrylate (n-BA), 20 g of methyl acrylate (MA), and 1 g of hydroxybutyl acrylate (HBA) were mixed instead of the monomer mixture prepared in Preparation Example 1, An acrylic polymer having a weight average molecular weight of 1,670,000 was prepared in the same manner as described in Preparation Example 1.

preparation Embodiment 3

[0065] Preparation Example 3: Preparation of Acrylic Polymer (A3)

[0066] Except for using a monomer mixture in which 59 g of n-butyl acrylate (n-BA), 40 g of methyl acrylate (MA), and 1 g of hydroxybutyl acrylate (HBA) were mixed in place of the monomer mixture prepared in Preparation Example 1, An acrylic polymer having a weight average molecular weight of 1,890,000 was prepared in the same manner as described in Preparation Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com