Acrylic pressure sensitive adhesive compositions

An acrylic pressure-sensitive adhesive, acrylic copolymer technology, applied in the direction of adhesive types, ester copolymer adhesives, adhesives, etc., can solve the problem of changing the adhesion, affecting the wettability of the anti-glare layer, and low-speed peeling Problems such as reduction in strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] [Preparation of Acrylic Copolymer]

[0069] A monomer mixture of 89.0 parts by weight of 2-ethylhexyl acrylate (2-EHA), 9.0 parts by weight of n-butyl acrylate (BA) and 2.0 parts by weight of hydroxyethyl acrylate (2-HEA) was added to Into a 1 L reactor equipped with nitrogen reflux and a temperature-adjusting cooling system, 100 parts by weight of ethyl acetate (EAc) was added thereto as a solvent. In order to remove the oxygen therein, nitrogen gas was passed for 1 hour under the condition of maintaining the temperature at 55°C, and then 0.05 parts by weight of azobisisobutyronitrile (AIBN) diluted in ethyl acetate at a concentration of 50% was added thereto as a reaction initiator. The mixture was reacted for 8 hours to obtain an acrylic copolymer.

[0070] [Mixing and coating procedure]

[0071] Add 3.0 parts by weight of hexamethylene diisocyanate (HDI) prepolymer as a crosslinking agent and 2.0 parts by weight of dibutyl phthalate to 100 parts by weight of the ...

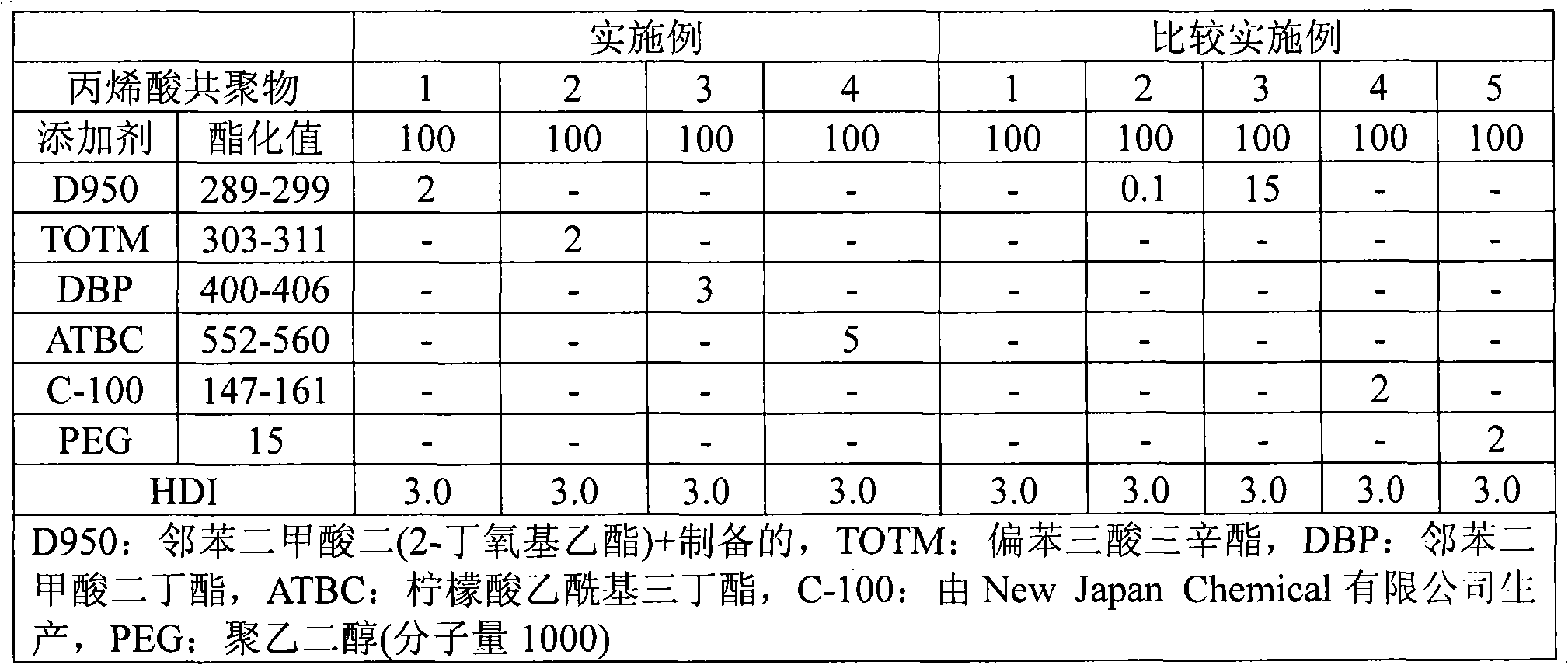

Embodiment 2~4 and comparative Embodiment 1~5

[0076] An acrylic copolymer was prepared by the same method as in Example 1 except using the components and ratios shown in Table 1. The units in Table 1 are parts by weight.

[0077] [Table 1]

[0078]

[0079]The peel strength, wettability and durability reliability of the protective films prepared in Examples 1 to 4 and Comparative Examples 1 to 5 were tested by the following methods, and the results are shown in Table 2.

[0080] A.180°peel strength

[0081] According to JIS Z 0237, the protective films prepared in Examples 1 to 4 and Comparative Examples 1 to 5 were adhered to the surface of triacetyl cellulose (TAC, Japan Fuji Film Co., Ltd.) A glare layer (AG, DNP Co., Ltd., Japan) was on the surface. These samples were kept at a temperature of 23°C and a relative humidity of 65% for 24 hours and at a temperature of 70°C for 100 hours. Peel strength was then measured using a tensile tester under the conditions of an angle of 180 degrees and separation speeds of 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com