Acrylic pressure sensitive adhesive compositions having plasticizer

An acrylic pressure-sensitive adhesive and composition technology, applied in the direction of adhesive types, ester copolymer adhesives, adhesives, etc., can solve the problem of not effectively suppressing the migration of antistatic agents, not pointing out, affecting water content And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

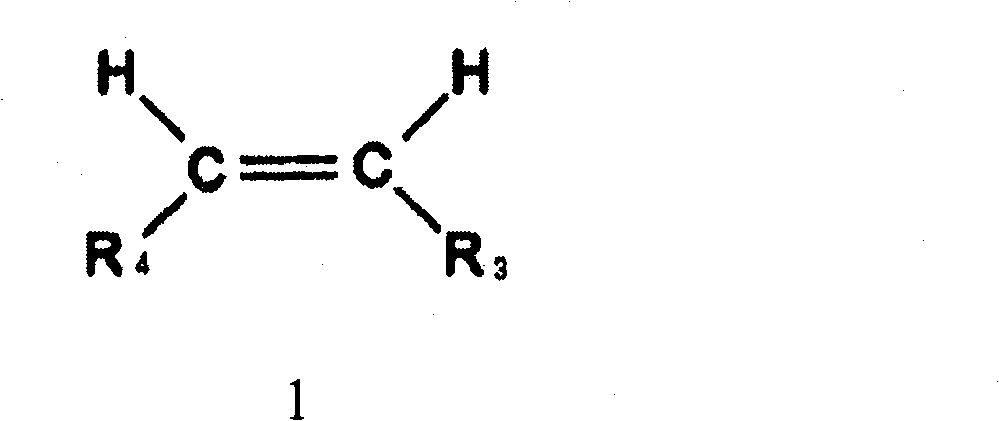

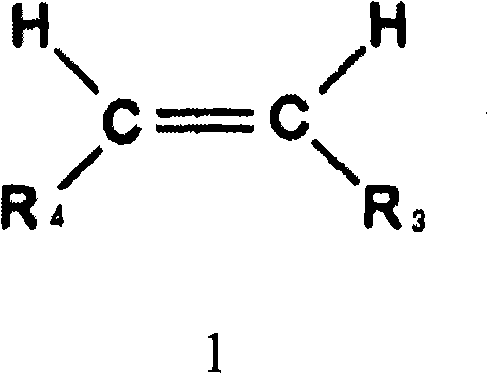

Method used

Image

Examples

Embodiment 1

[0094] (Preparation of Acrylic Copolymer)

[0095] A monomer mixture consisting of 89.0 parts by weight of 2-ethylhexyl acrylate (2-EHA), 9.0 parts by weight of n-butyl acrylate (BA), and 2.0 parts by weight of 2-hydroxyethyl acrylate (2-HEA) It was charged into a 1 L reactor equipped with a cooling system for nitrogen reflux and easy to adjust the temperature, and then 100 parts by weight of ethyl acetate (EAc) was added as a solvent. To remove oxygen, nitrogen was purged for 1 hour and the temperature was maintained at 55°C. 0.05 parts by weight of azobisisobutyronitrile (AIBN) diluted to a concentration of 50% in ethyl acetate as a reaction initiator was added to the above mixture, and reacted for 8 hours to prepare an acrylic copolymer.

[0096] (combining and coating process)

[0097] With 100 parts by weight of the acrylic copolymer prepared above, 3.0 parts by weight of 1, the prepolymer of 6-hexamethylene diisocyanate (HDI), 2.0 parts by weight of PEL-20A (with the p...

Embodiment 2~5 and comparative Embodiment 1~5

[0102] The same method as in Example 1 above was carried out except that the components and ratios in Example 1 were used as shown in Table 1 below. The units in Table 1 are parts by weight.

[0103] Table 1

[0104]

[0105]

[0106] Using the protective films prepared in the above Examples 1 to 5 and Comparative Examples 1 to 5, haze, wettability, release strength and durability reliability were measured by the following methods, and the results are shown in Table 2 below.

[0107] 1) Turbidity

[0108] After removing the release film attached to the pressure-sensitive adhesive layer from the protective films prepared in the above Examples 1 to 5 and Comparative Examples 1 to 5, the protective films were soaked in deionized water at room temperature and Leave for 1 hour. Moisture covering the periphery of the protective film was then removed to measure a haze value with a reflection-transmittance meter (HR-100, manufactured by Murakami Color Res. Lab.). When the prot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com