Special receiving apparatus for ball valve blanking and discharging kneader

A technology of material receiving device and kneader, which is applied in the direction of mixer, mixer accessories, dissolving, etc., can solve the problems of inconvenient discharge of materials, inconvenient removal of material receiving box, and influence on production efficiency, so as to reduce labor intensity and facilitate daily life Maintenance and overhaul, involving reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

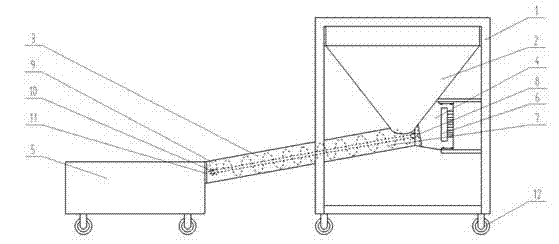

[0017] In order to realize the design original intention of the present invention, the feeding device 4 includes a driving motor 6 and a screw 7 . The drive motor 6 is arranged on the outer surface of the corresponding side of the connection position of the feed pipe 3 on the material receiving box 2, and the drive motor 6 drives the screw rod 7 to work. One end of the screw rod 7 is connected with the drive shaft 8 of the drive motor 6, and the other end is connected with the drive shaft 8 of the drive motor 6. The fixed frame 9 that is arranged on the delivery pipe 3 is connected. The fixed frame 9 is fixedly connected to the top position of the inner surface of one end of the feeding pipe 3, and the middle position of the fixed frame 9 is provided with a bearing 10, and the middle of the bearing 10 is provided for the screw rod 7 to pass through. The material is conveyed to the receiving box 2 by means of the screw 7, and the position of the screw 7 is fixed to reduce the o...

Embodiment 2

[0019] On the basis of embodiment 1, the feeding device 4 and the feed pipe 3 are kept inclined as a whole, and the end of the feed pipe 3 connected to the receiving box 2 is higher than the end of the feed pipe 3 connected to the material collection box 5; the inclination angle is 5 -20°, which is convenient for the accumulation of materials in the receiving box 2 and the rapid discharge of materials.

Embodiment 3

[0021] On the basis of Embodiment 1 or 2, a filter screen 11 is provided at the connection between the feeding pipe 3 and the material collection box 5, which can prevent the viscous material from being mixed with large and fast granular substances.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com