A swinging folded plate photocatalytic reaction device

A photocatalytic reaction and plate-type technology, which is applied in chemical/physical processes, chemical instruments and methods, etc., to achieve the effects of improving light energy utilization, increasing contact area, and increasing illuminated area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

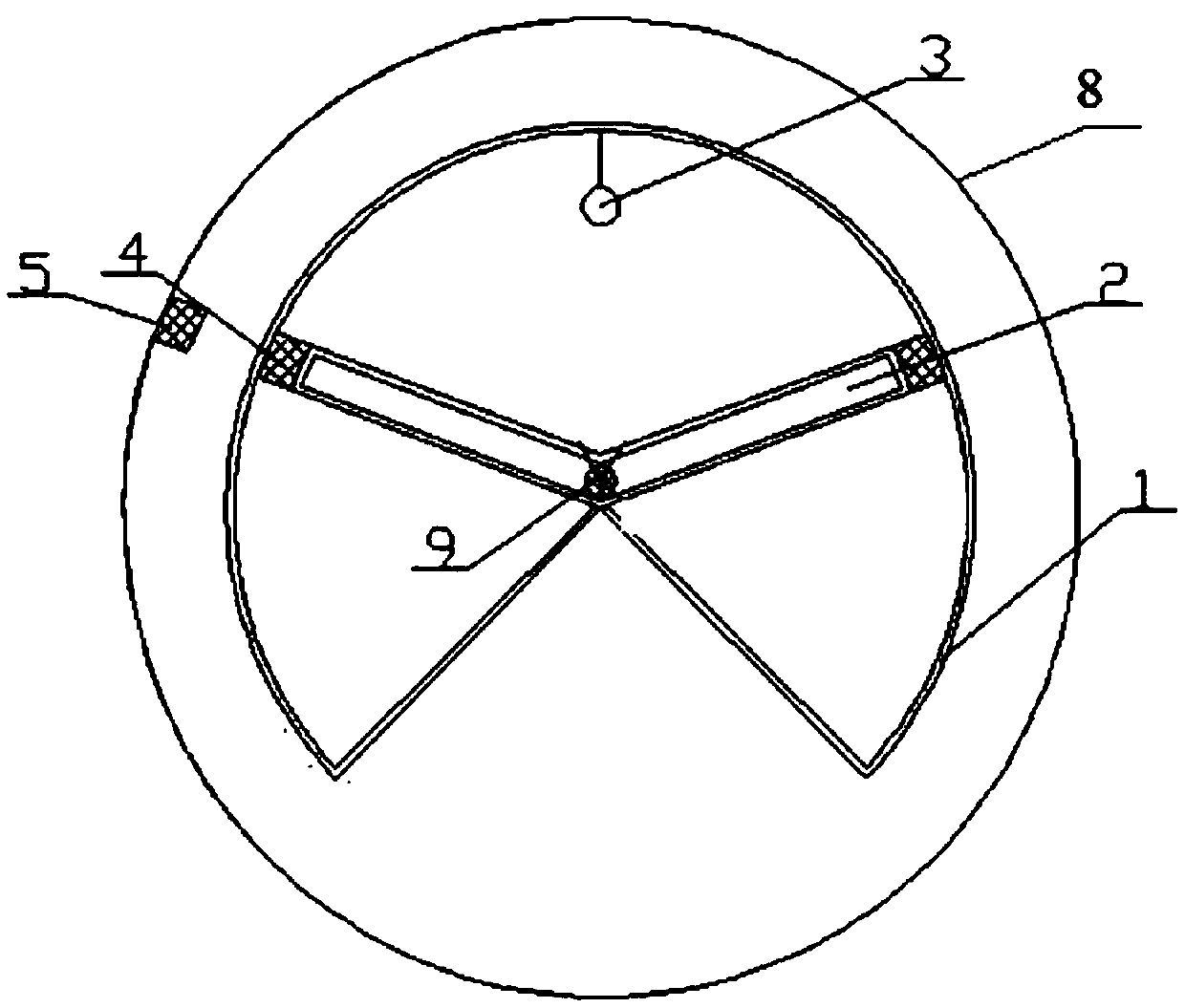

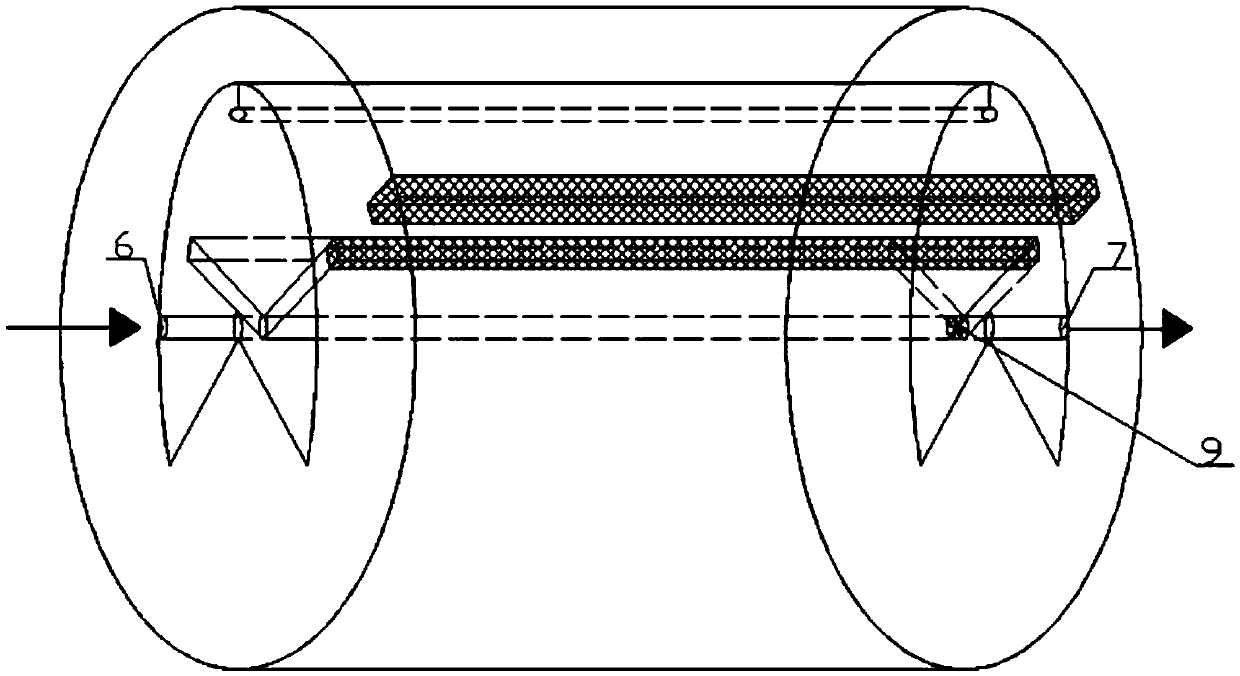

[0022] Such as Figure 1-3 As shown, the device is implemented in the following steps,

[0023] 1) Open the air inlet 6 to fill the catalyst.

[0024] 2) Turn on the motor, and the permanent magnet 5 drives the folded plate 2 to swing.

[0025] 3). Pass the reactant gas from the air inlet 6 and open the air outlet 7 to keep the gas circulating.

[0026] 4) Turn on the light source 3, and the catalyst fully reacts with the reaction gas.

[0027] 5). After the reaction is completed, a certain amount of inert gas is introduced and after the reaction gas has all flowed out from the gas outlet 7, the motor and the light source 3 are turned off.

[0028] 6) Open the air inlet 6 and take out the used catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com