Micro-pipeline-based liquid droplet generation method

A micro-pipe and droplet technology, which is applied in the direction of granulating raw materials, mixing methods, chemical instruments and methods, etc., can solve the problems of high cost and difficulty in precise control of droplet volume, so as to improve accuracy and efficiency, avoid Evaporation effects, simplified extraction and effects of storage steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

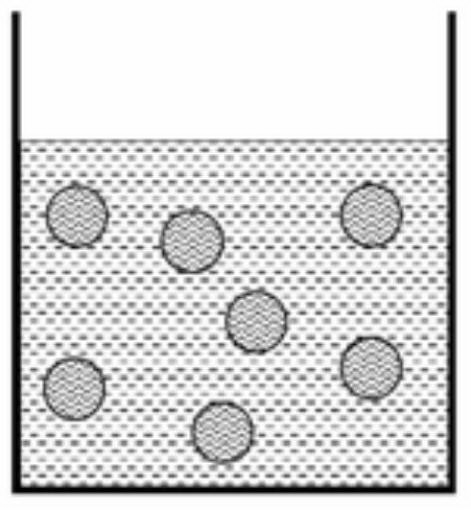

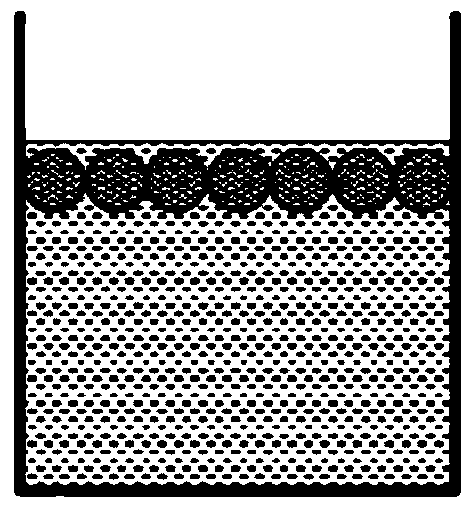

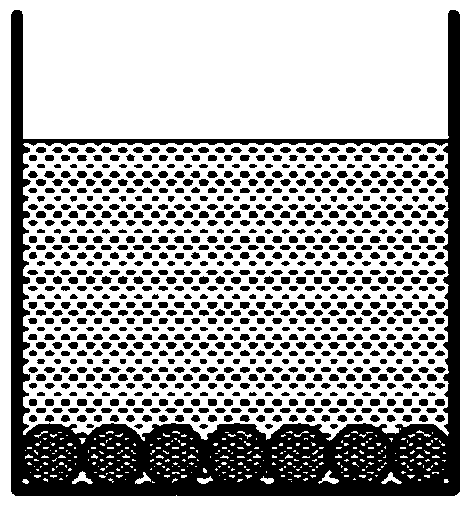

[0086] Figure 4 It is a schematic diagram of the operation steps of the droplet generation method provided in Example 1 of the present application. Figure 4 Among them, 1 is a quartz capillary, 2 is a reservoir, 3 is mineral oil, 4 is a pure water droplet, and 5 is pure water with an injection volume of 5 nanoliters. The inner diameter of the quartz capillary 1 is 25 microns, the outer diameter is 50 microns, and the length is 5 cm. Before use, the quartz capillary 1 is pre-silanized with dichlorodimethylsilane to make the mouth of the capillary hydrophobic. The upper end of the quartz capillary 1 is connected with a syringe pump (Harvard Apparatus, Pico Elite, not in Figure 4 Shown in ) connection, the connection gap is filled with epoxy resin glue to ensure airtightness. The syringe pump is equipped with a syringe with a volume of 10 microliters (not in Figure 4 shown in ). Before use, fill the syringe, Teflon thin tube, and quartz capillary 1 with pure water, and ch...

Embodiment 2

[0091] According to the method of Example 1, a droplet with a volume of 2.5 nanoliters was obtained; the difference was that the flow rate of the syringe pump was 60 nanoliters / minute, and the injection time was changed to 2.5 seconds.

Embodiment 3

[0093] According to the method of Example 1, a droplet with a volume of 2.5 nanoliters was obtained; the difference was that the flow rate of the syringe pump was changed to 30 nanoliters / minute, and the injection time was 5 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com