Method and equipment for coating and scraping edges of battery separator

A battery diaphragm and edge scraping technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of convex edges of the coated diaphragm, waste of resources, etc., to reduce slurry loss and strong applicability , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

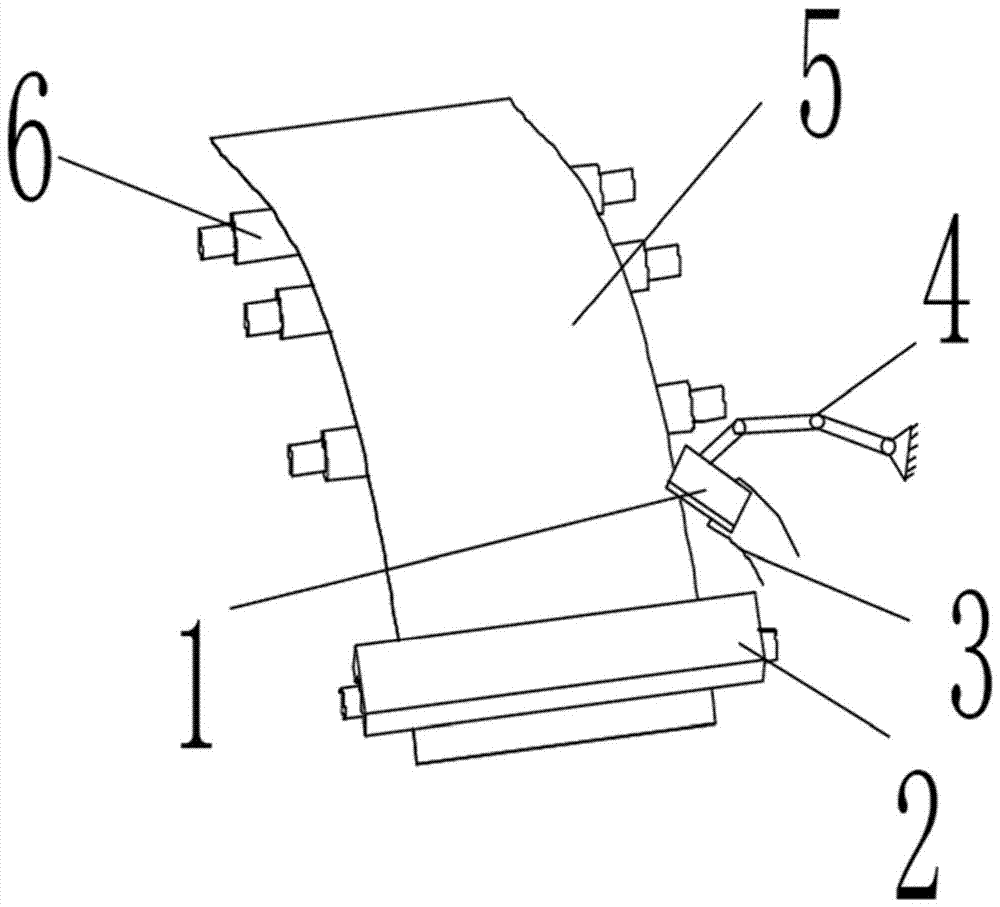

[0025] The battery diaphragm coating scraping equipment of the present embodiment, such as figure 1 As shown, it includes a scraper 1, a collection pipe 3 and a rotating mechanism 4. The front end of the collection pipe 3 is fixedly connected with the scraper 1, and one end of the scraper 1 is inserted into the inside of the collection pipe 1 from the nozzle, and the end of the collection pipe 1 is used for connecting with the scraper 1. The coating material box 2 is connected; the rotating mechanism 4 is connected with the front end of the collection pipe 3, and is used to realize the opening and closing of the scraper 1 and the diaphragm 5 and the adjustment of the position and angle of the scraper 1.

[0026] The battery diaphragm coating scraping equipment of the present embodiment, such as figure 1 As shown, when in use, fix the rotating mechanism 4 at a suitable position of the coating machine, adjust the position and angle of the scraper 1 through the rotating mechanism...

Embodiment 2

[0028] The method for coating and scraping the battery separator of the present embodiment uses the equipment for coating and scraping the battery separator as in Example 1, which specifically includes the following steps:

[0029] 1) Adjust the position and angle of the scraper through the rotating mechanism. The scraper is made of metal, the thickness is 0.2mm, the angle of the scraper edge is 5°, and the width of the scraping treatment is 1mm;

[0030] 2) Turn on the coater, and the diaphragm after coating the slurry moves at a rate of 3m / min (the base material of the diaphragm is PP, and the coating slurry is ceramic slurry), and the slurry is coated without drying with a scraper. The diaphragm is scraped (the slurry coated on the diaphragm is in a liquid and flowable state), and the movement direction of the scraper and the diaphragm to be scraped is at an angle of 80°. Under the relative action between the diaphragm and the scraper, The scraped liquid slurry flows into t...

Embodiment 3

[0032] The method for coating and scraping the battery separator of the present embodiment uses the equipment for coating and scraping the battery separator as in Example 1, which specifically includes the following steps:

[0033] 1) Adjust the position and angle of the scraper through the rotating mechanism. The scraper is made of metal, the thickness is 1.0mm, the angle of the scraper edge is 60°, and the width of the scraping treatment is 100mm;

[0034] 2) Turn on the coater, and the diaphragm after coating the slurry moves at a rate of 200m / min (the base material of the diaphragm is PE, and the coating slurry is ceramic slurry), and the scraper is used to dry the coating slurry without drying. The diaphragm is scraped (the slurry coated on the diaphragm is in a liquid and flowable state), and the movement direction of the scraper and the diaphragm to be scraped is at an angle of 5°. Under the relative action between the diaphragm and the scraper, The scraped liquid slurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com