Balloon catheter fluid automatic clearing system

一种清除系统、流体的技术,应用在导管系统领域,能够解决压力传感器宽误差范围、球囊壁破裂、损伤等问题,达到优化体积、早发现和响应的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following describes in detail the presently most preferred modes of carrying out the invention. The description is not intended to limit the present invention, but is only used to illustrate the basic principles of the specific embodiments of the present invention. The protection scope of the present invention is defined by the appended claims.

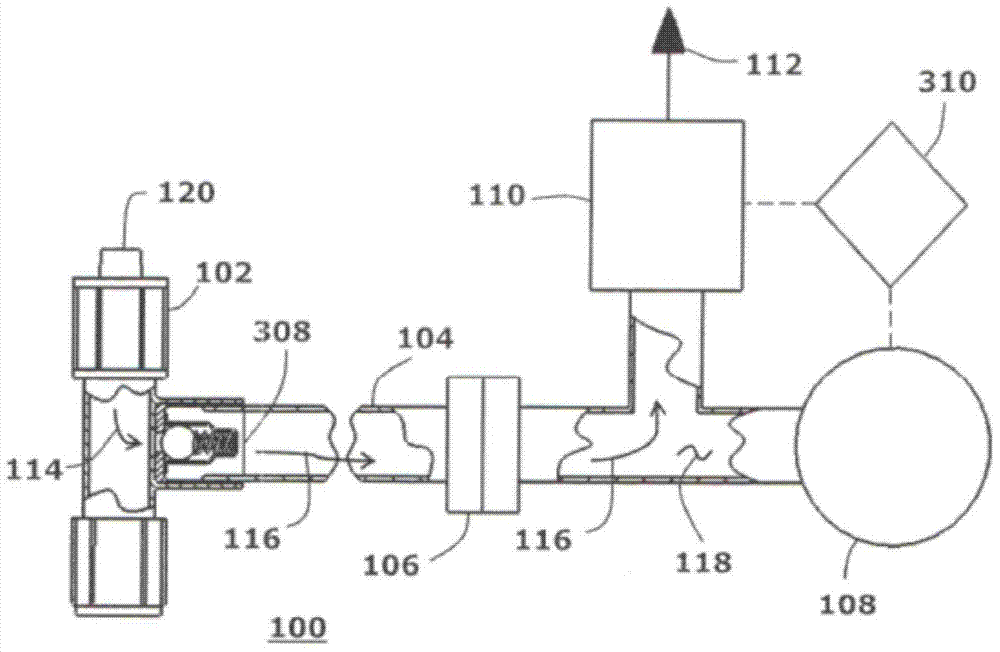

[0031] Such as figure 1As shown, the present invention provides a fluid removal system 100 capable of receiving fluid 114 from an inlet 120 of a pressure relief valve 102 . The pressure relief valve 102 is a standard spring actuated pressure relief valve with a preset burst pressure differential in the range of 20 psig to 750 psig. Pressure relief valve 102 functions like a check valve, allowing flow in one direction and blocking flow in the opposite direction. Fluid can pass through the relief valve 102 only when the internal fluid pressure rises above the burst pressure of the relief valve 102 . For the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com