Electric internal clamp for pipeline

An internal counterpart and electric technology, applied in the direction of tubular objects, auxiliary devices, applications, etc., can solve the problems of increased construction costs, complex structures, and reduced work efficiency, and achieve improved construction efficiency, good robustness, and economical construction cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

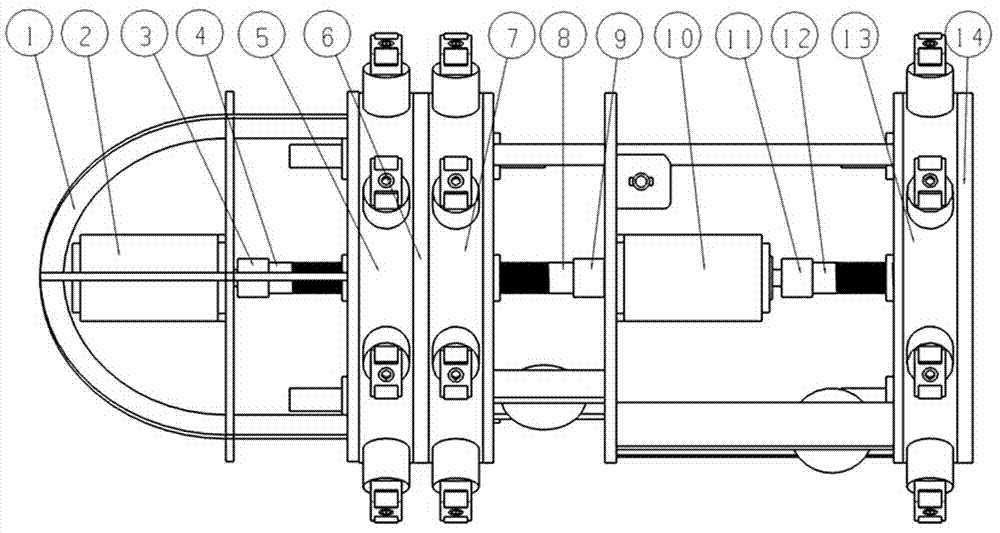

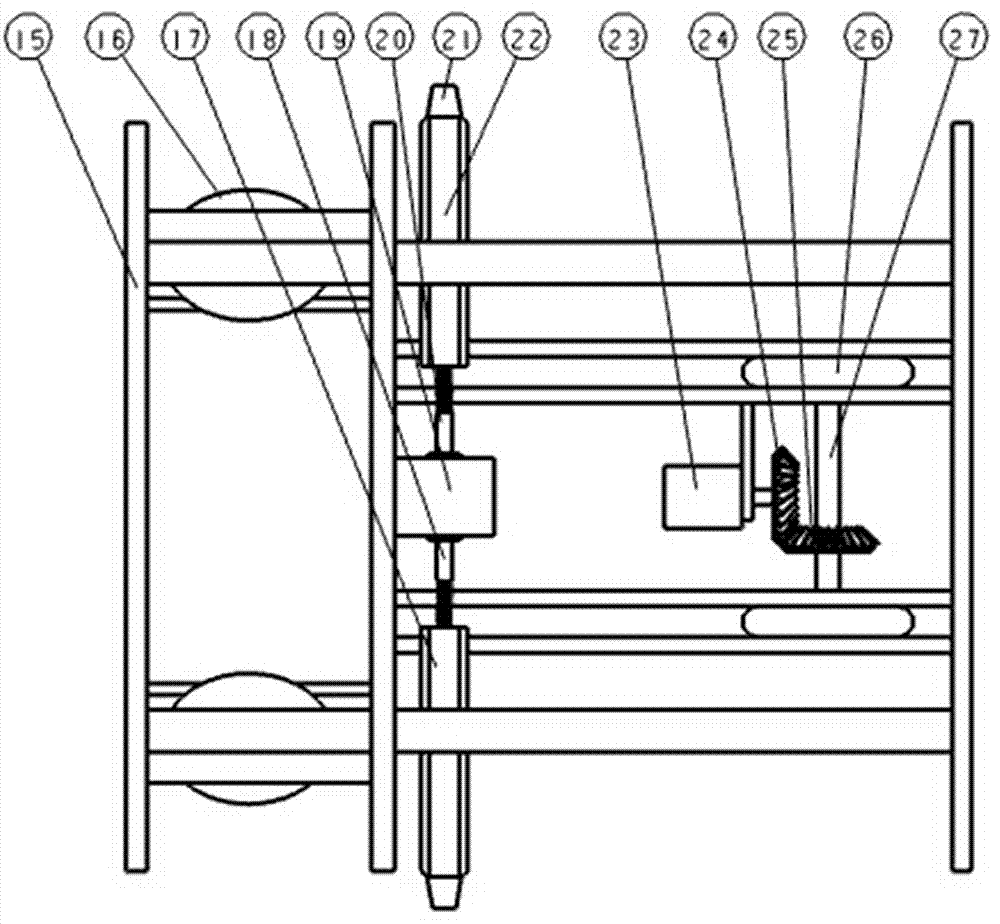

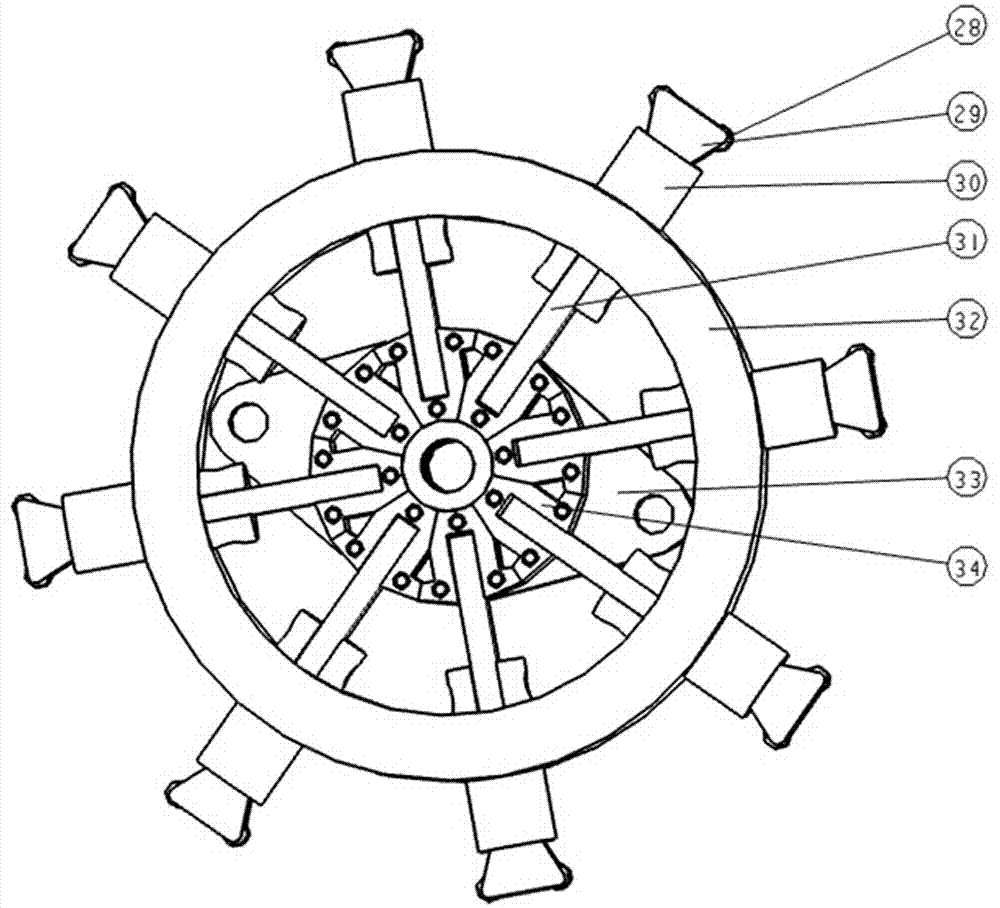

[0034] See figure 1 , 2 , 3, 4, 5. In the electric pipeline internal counterpart of the present invention, its counterpart working part, driving part and braking part are all connected with the motor;

[0035] The counterpart working part is three sets of the same coaxial counterpart tensioning mechanism, and the front counterpart tensioning mechanism 5 and the middle counterpart tensioning mechanism 7 are bonded together;

[0036] The front counterpart tensioning mechanism 5 and the arc-shaped guide cage front body 1 constitute the front support part;

[0037] The middle counterpart tensioning mechanism 7 and the rear counterpart tensioning mechanism 13 located at both ends of the rear body 15 form a rear support part with the rear body 15;

[0038] The middle of the front counterpart tensioning mechanism 5 and the middle counterpart tensioning mechanism 7 is fixedly connected with a disc-type two-way guide column 6, and the rear counterpart tensioning mechanism 13 at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com