Spring-free high-elasticity fiber mattress

A technology of elastic fibers and mattresses, which is applied in the direction of spring mattresses, mattresses, stuffed cushions, etc., can solve the problems of pressure resistance and elastic elasticity, increase the density of polyester fiber materials, etc., and achieve pressure resistance And the effect of elasticity can not last

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

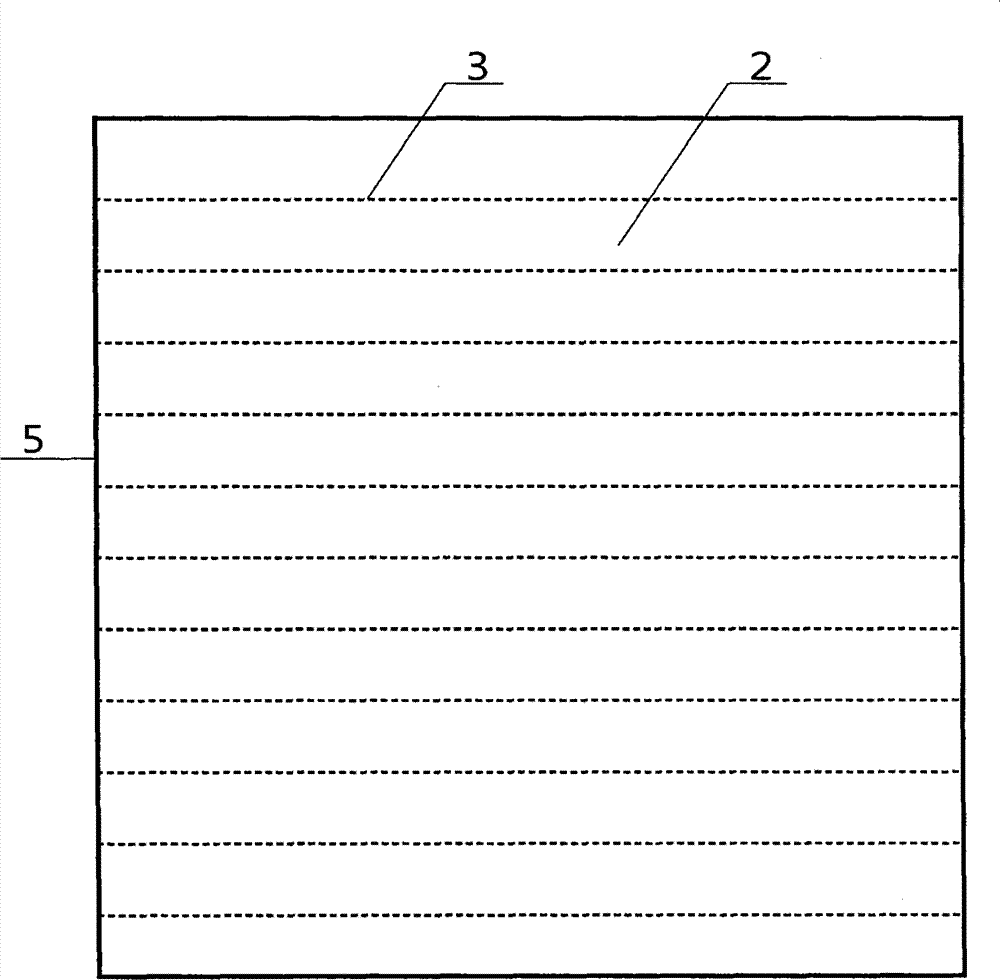

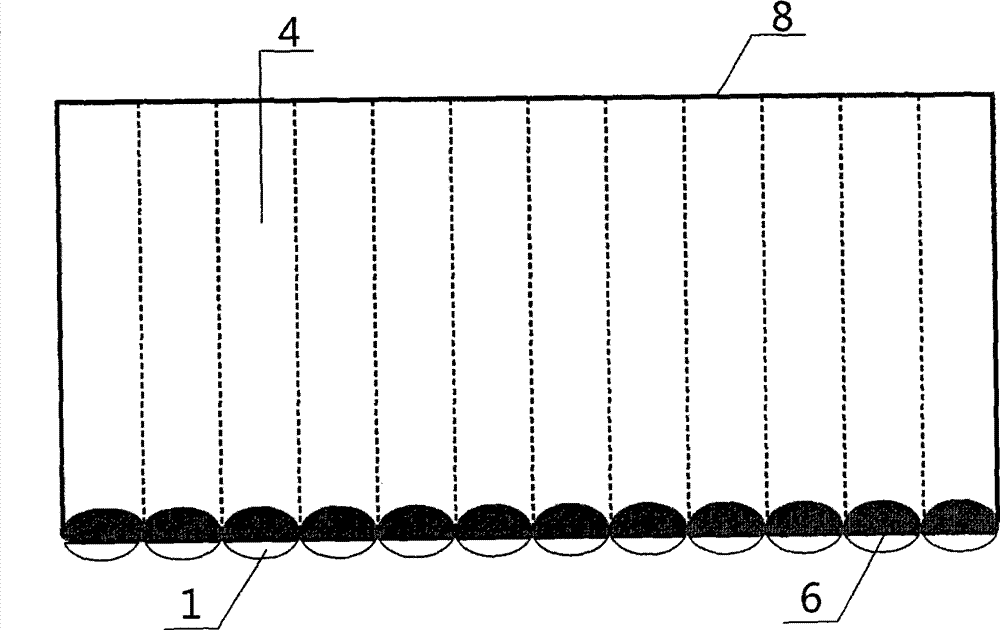

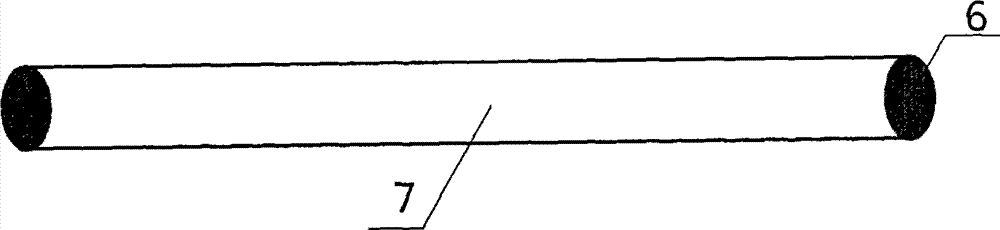

[0009] The technical scheme of the present invention is realized like this, as Figure 1-3 As shown, the mattress is mainly composed of a pad carcass and a cotton column filler inside. The hard cotton 1 with a thickness of 2-4 cm and a weight of 200-400 grams per square meter is arranged in the middle of the upper and lower layers of the textile layer 2. The textile layer is divided into two types: the fabric layer and the lining layer, and the sewing threads 3 are equidistantly spaced. Puncture and sew to form a pad carcass 5 composed of several parallel filled cloth bags 4, and fill the narrow and long cloth bags corresponding to the length and width of the filled cloth bags 4 into polyester fiber cotton batting 6 to form a compact and solid cotton cylinder 7. Cotton cylinders 7 are placed side by side and horizontally into the filling cloth bag 4 corresponding to the cushion carcass 5 to form a mattress body 8. The fabric layer of the cushion carcass is made of fabric, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com