Preparation method for FDY ultra-fine nylon fibers

A technology of fiber and nylon, which is applied in the field of FDY ultrafine denier fiber preparation, can solve the problems of thick and thin filaments, uneven elasticity, wool and other problems of finished silk, and achieve high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

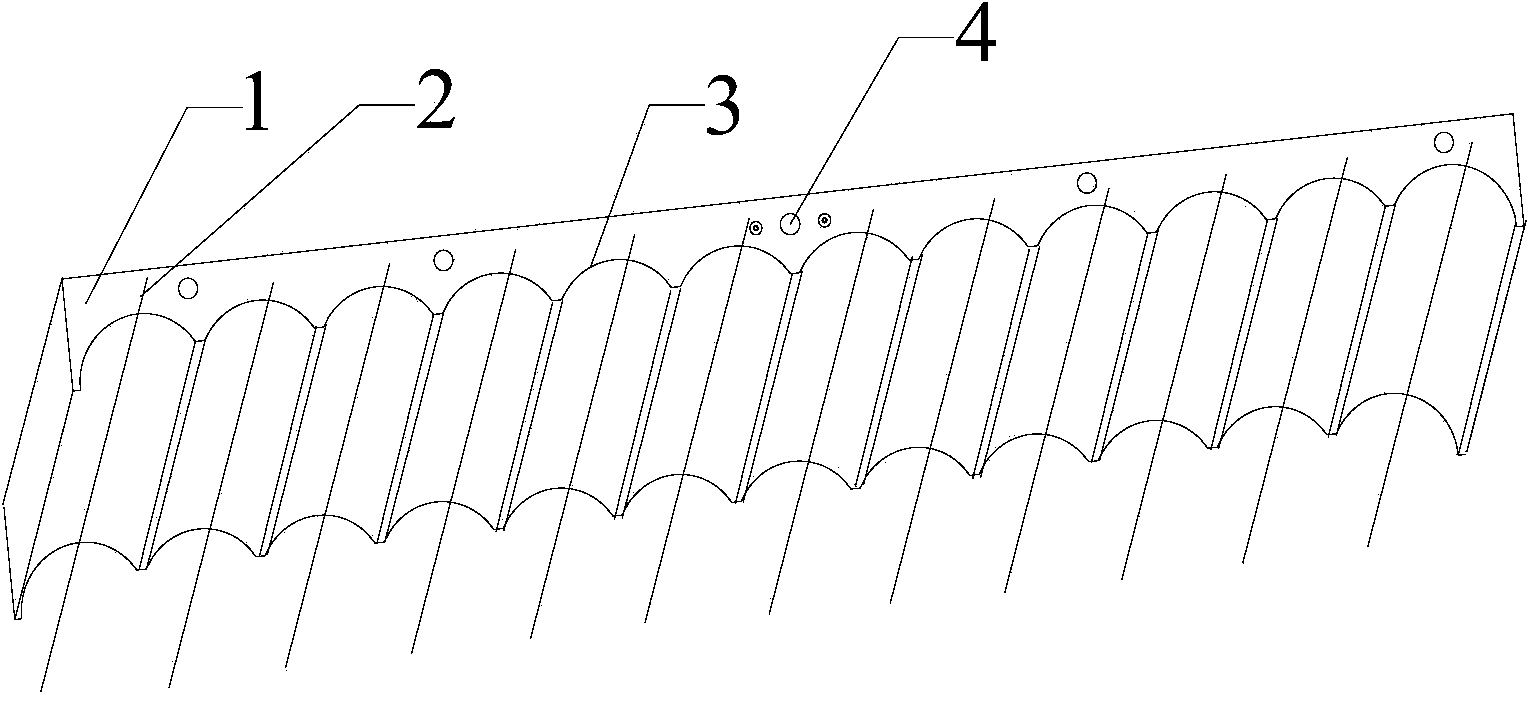

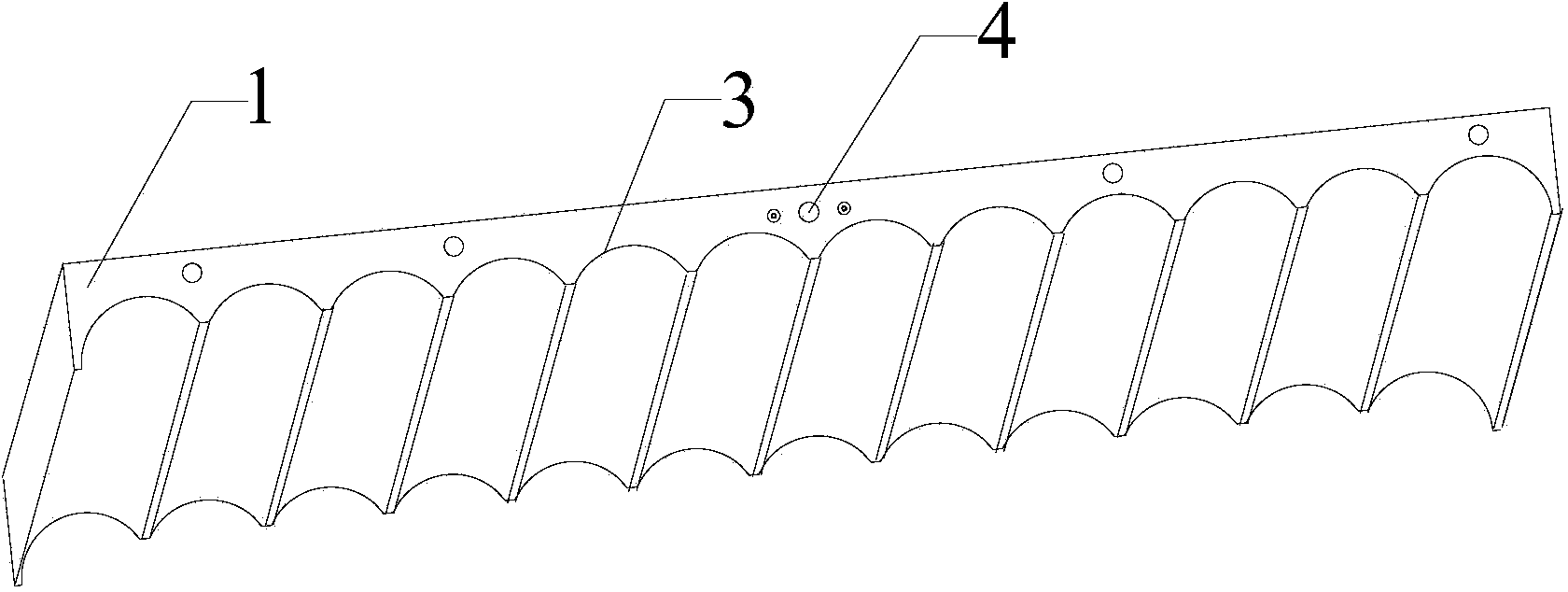

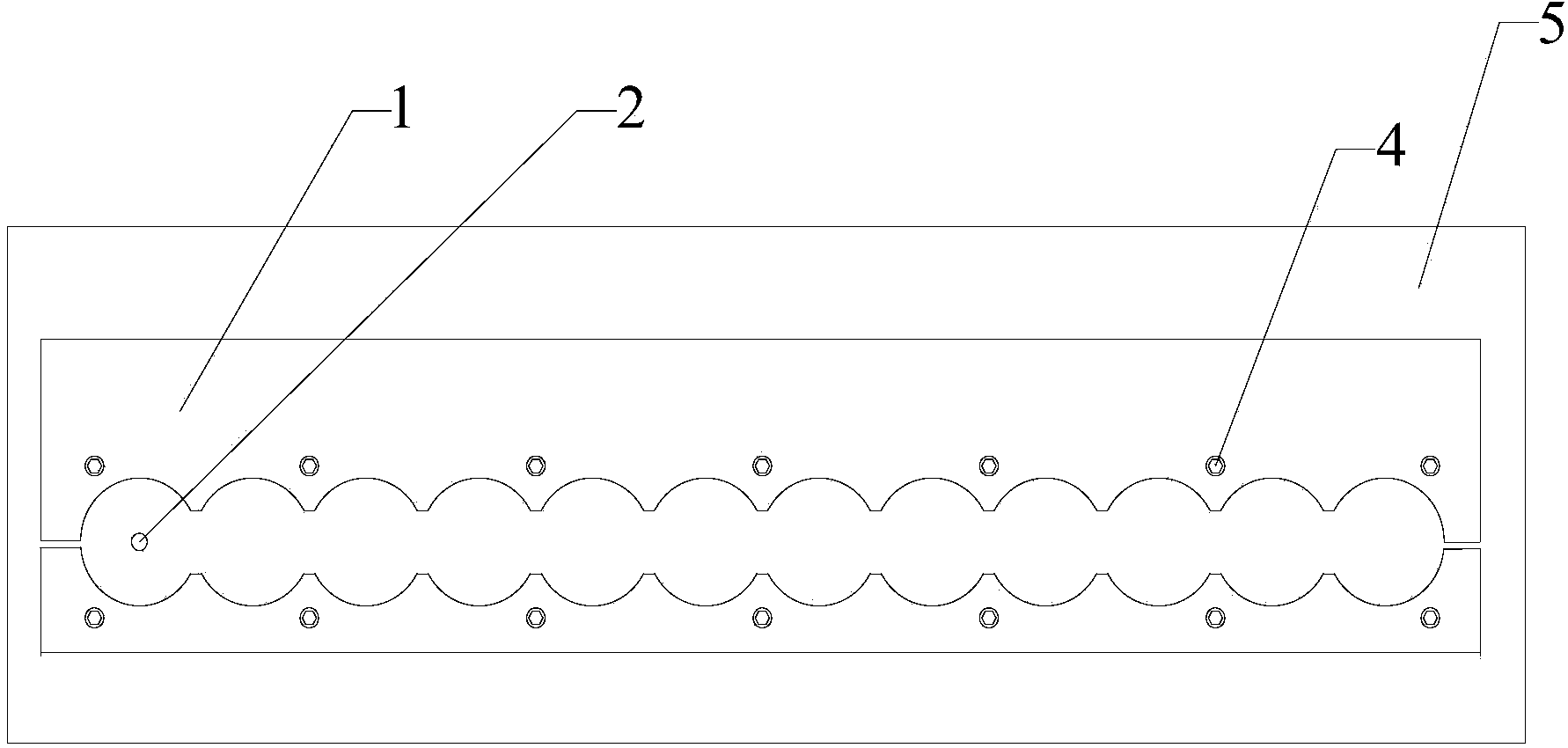

[0020] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

[0021] The most critical idea of the present invention is: the preparation method of the FDY ultra-fine denier fiber of the present invention controls the temperature at the outlet of the spinning assembly at 200-250°C, so that the heat will not be enriched, and the temperature will not be increased beyond the controlled temperature. If the drop is too fast, the FDY superfine denier fiber produced has elasticity, and the product has clear lines and higher quality.

[0022] Please refer to figure 1 , figure 2 and image 3 , a production process of FDY superfine denier, comprising the steps of:

[0023] (1) Nylon is fed into the screw extruder through the nylon inlet to control the nylon inlet temperature.

[0024] (2) Nylon is extruded by a screw extruder,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com