Patents

Literature

41results about How to "Will not enrich" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

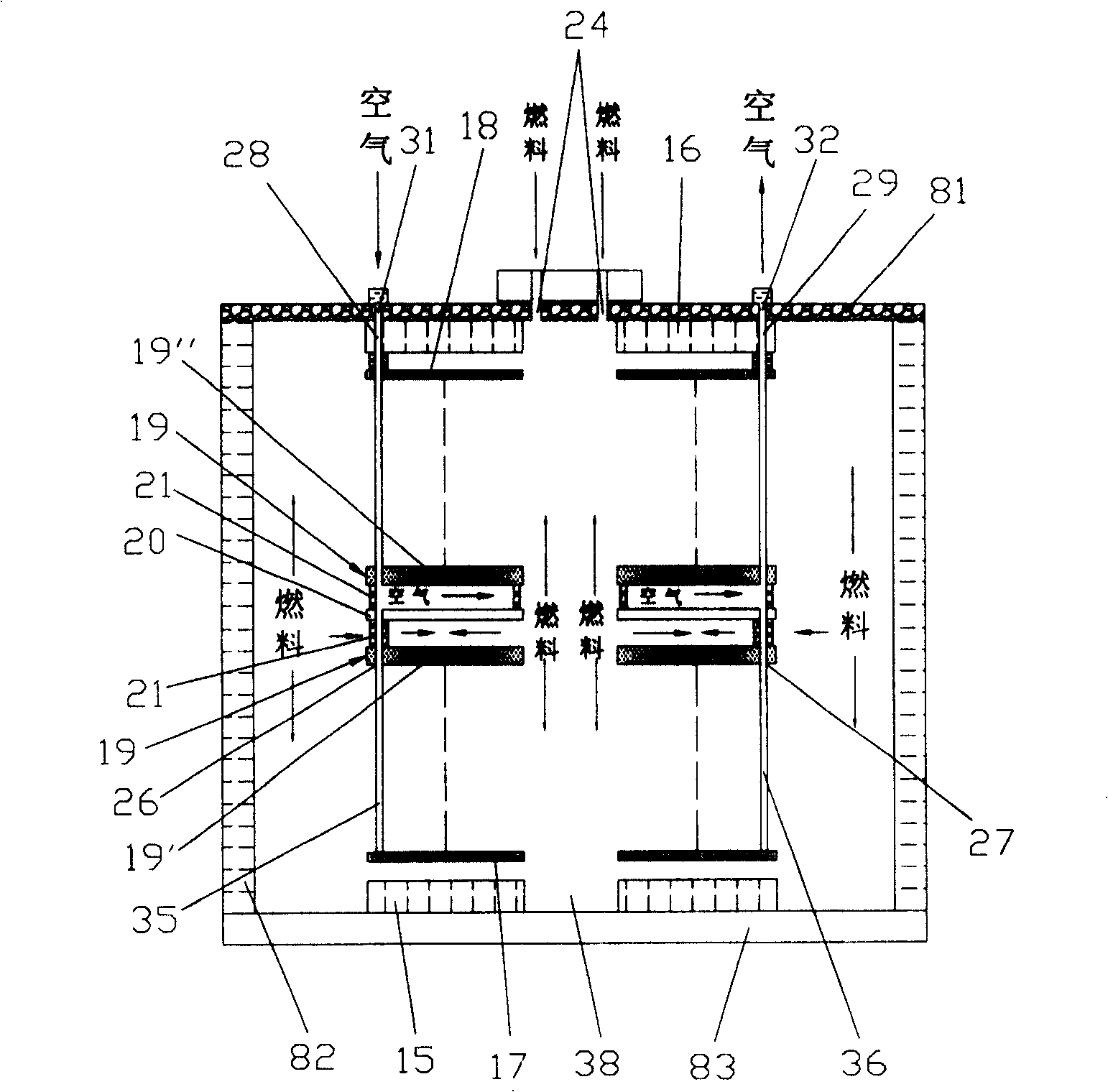

Continuous Casting Process of Steel for High Titanium Alloy Welding Rod

ActiveCN102266925AAvoid secondary oxidationGuaranteed stabilityMelt-holding vesselsTundishElectromagnetic stirring

The invention relates to a continuous casting process of the metallurgy field and discloses a continuous casting process of steel for high titanium alloy welding rods. Full protection pouring is used during continuous casting, and long nozzle argon sealing protection pouring is used from a steel ladle to an intermediate ladle. The whole built-in submersed nozzle protection pouring is used from the intermediate ladle to a crystallizer. A covering agent is used by molten steel in the intermediate ladle. The electromagnetic stirring is used in the process of continuous casting and pouring. Full automation liquid level detection is carried out on the liquid level of the crystallizer. The continuous casting pulling speed is controlled automatically according to the degree of superheat of the intermediate ladle. The degree of superheat of the intermediate ladle in a first continuous casting and pouring furnace is controlled at 30-40 degrees centigrade. The pouring pulling speed is controlled in a range of 1.8-2.4 m / min. The protection slag is composed of the following components measured in percentage by weight: 0.80 + / - 0.15% of R, 35.0 + / - 3.5% of SiO2, 28.0 + / - 3.5% of CaO, less thanor equal to 5.0% of Al2O3, less than or equal to 4.0% of Fe2O3, less than or equal to 5.0% of MgO, 4.5 + / - 1.5% of F<->, 5.0 + / - 2.0% of K2O + Na2O and 12.0 + / - 2.5% of solid C. According to the continuous casting process, the molten steel is prevented from second oxidization in the process of pouring effectively; the stability of titanium in the molten steel is ensured; protection slag is prevented from denaturing; and the quality of the surface of a casting blank is enhanced.

Owner:NANJING IRON & STEEL CO LTD

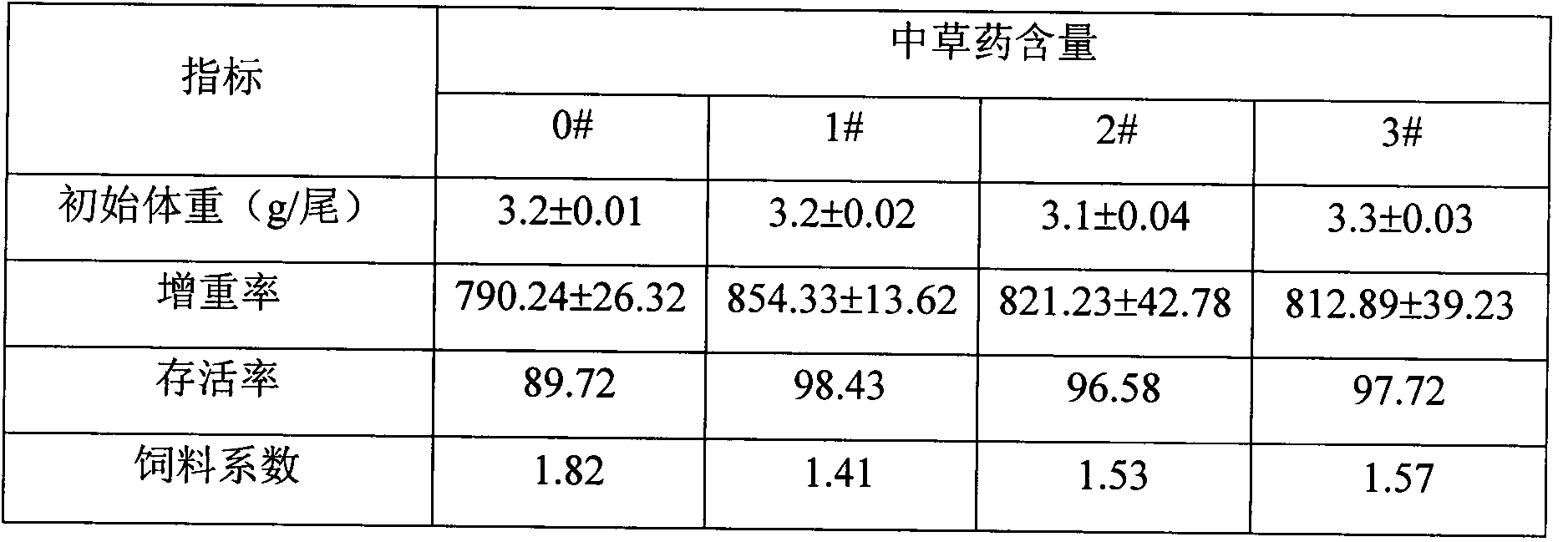

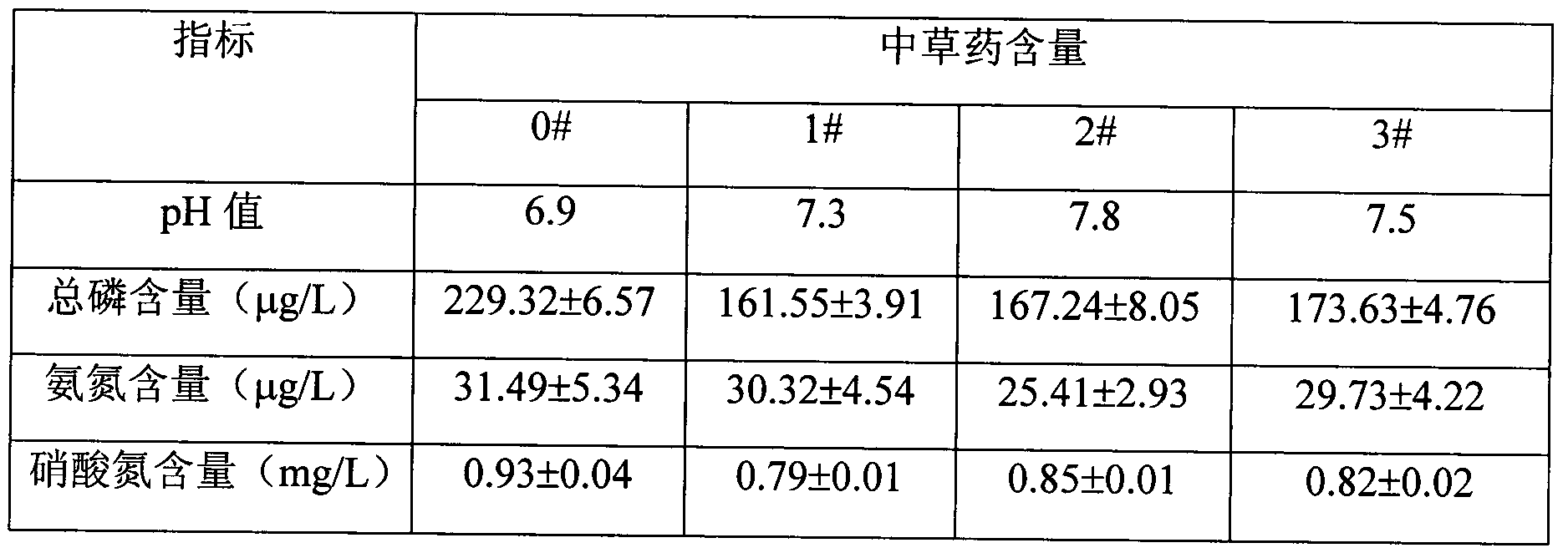

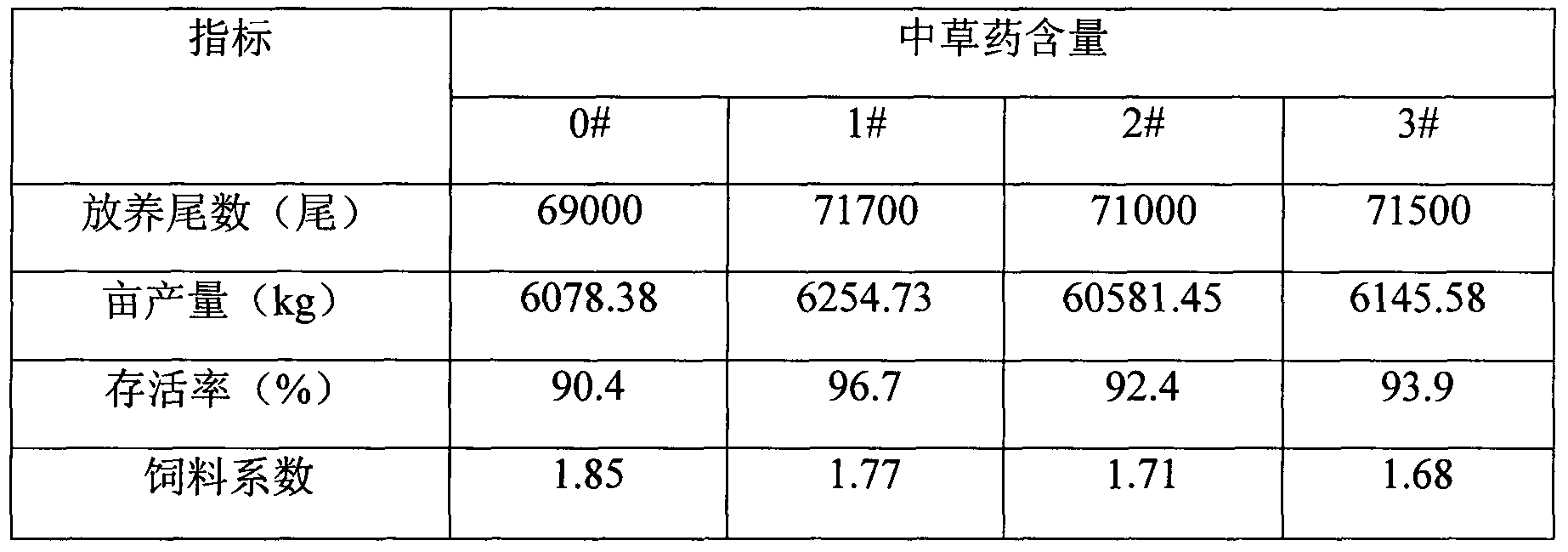

Environmentally-friendly snakehead fish feed containing Chinese herbal medicinal components, and preparation method thereof

InactiveCN104106735AHarm reductionReduce diseaseFood processingClimate change adaptationAdditive ingredientPeanut meal

The invention discloses an environmentally-friendly snakehead fish feed containing Chinese herbal medicinal components, and a preparation method thereof. The feed comprises 20.0-25.0 parts of flour, 3.0-5.0 parts of chicken powder, 28.0-33.0 parts of fish meal, 5.0-6.0 parts of peanut meal, 1.0-18.0 parts of a cuttlefish paste, 20.0-25.0 parts of soybean meal, 1.0-1.5 parts of fish oil, 2.0-4.0 parts of soybean oil, 1.0-2.0 parts of calcium dihydrogen phosphate, 0.4 parts of composite vitamin, 0.5-1.0 part of composite mineral matter, 0.03 parts of a mildew inhibitor, 0.1 parts of choline chloride, 6-15 parts of licorice root, 8-12 parts of radix bupleuri, 6-10 parts of dried orange peel, 4-13 parts of Radix Scutellariae, 6-15 parts of Chinese magnoliavine and 8-16 parts of Rheum officinale. The method comprises the following steps: 1, weighing basic components and Chinese herbal medicine additives; 2, preparing the Chinese herbal medicine additives for later use; and 3, mixing the basic components with the Chinese herbal medicine additives, and carrying out cooling and drying.

Owner:JIANGSU AGRI ANIMAL HUSBANDRY VOCATIONAL COLLEGE

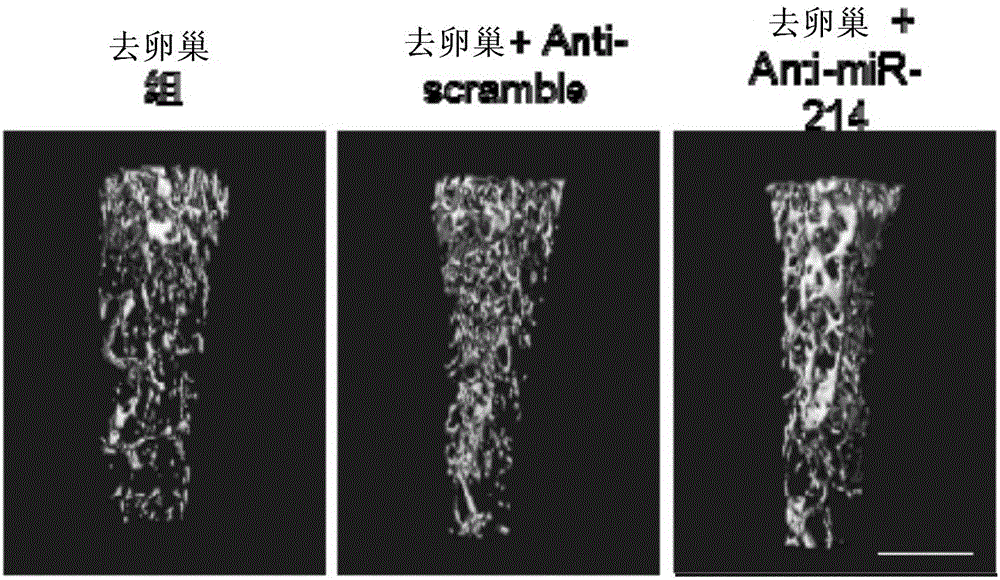

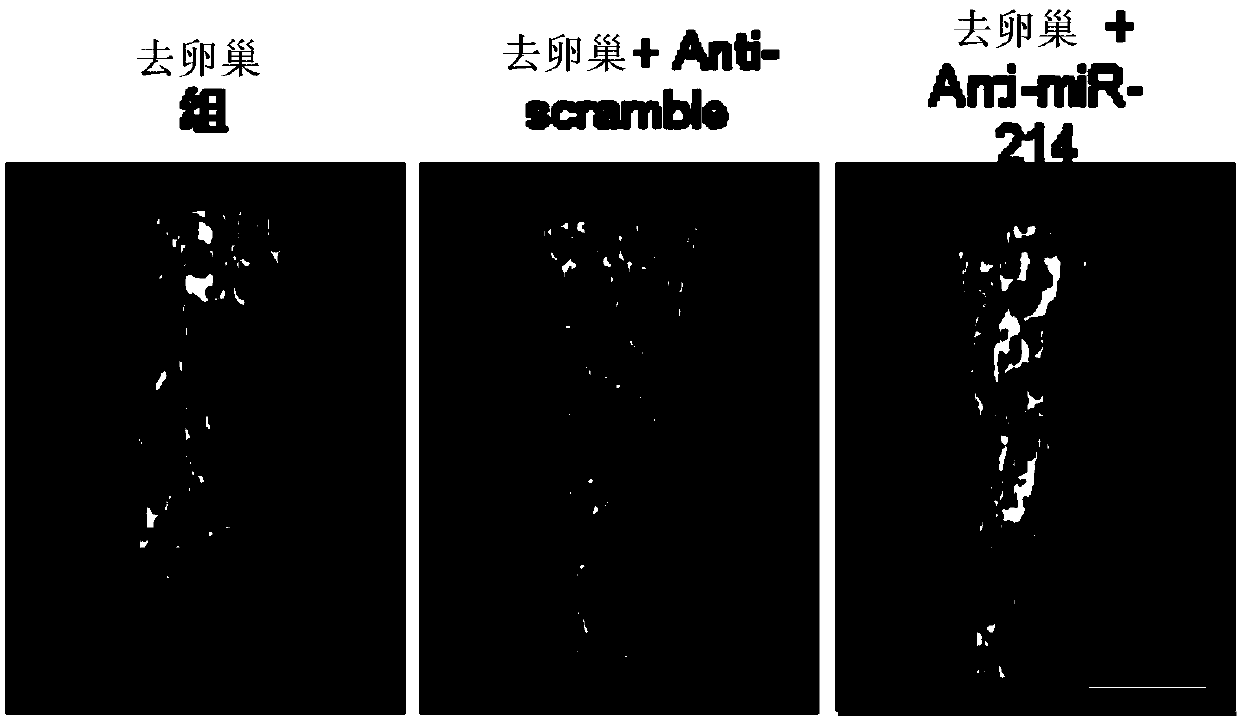

An osteoblast targeted vector constructed based on a polypeptide and preparation and applications thereof

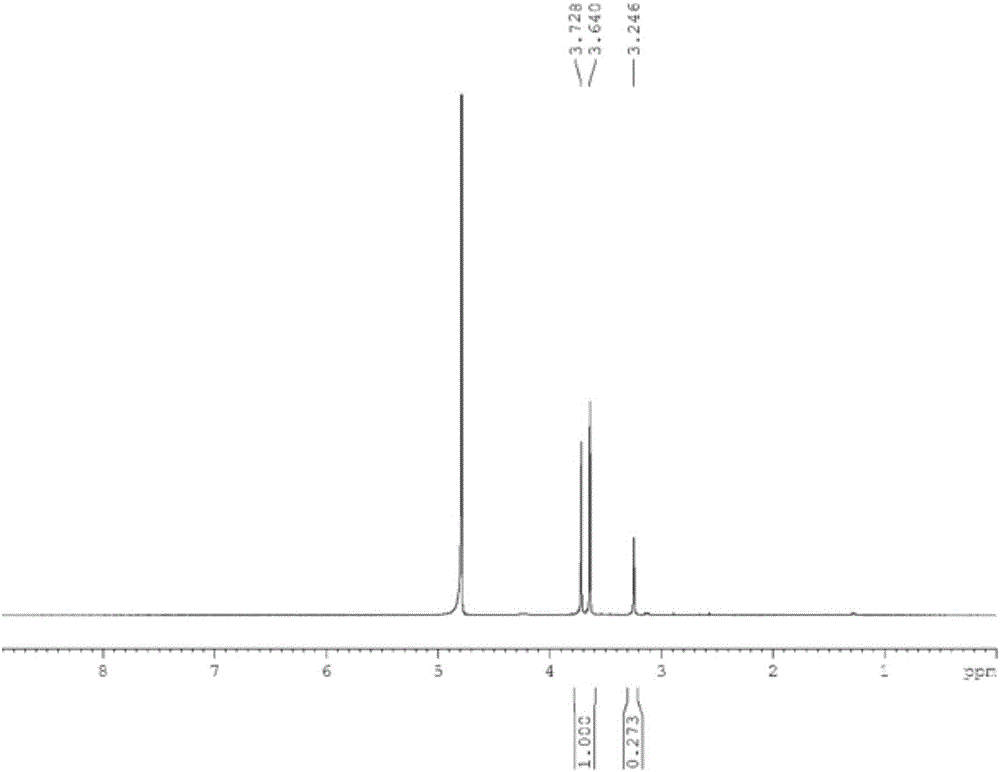

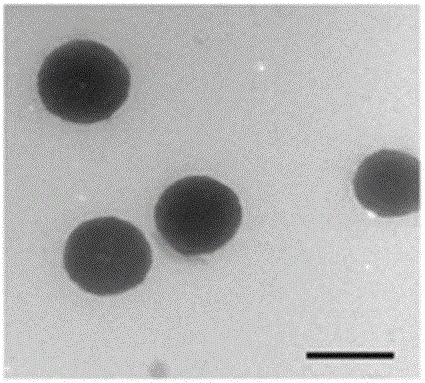

InactiveCN106039316ALittle side effectsImprove targetingPowder deliverySkeletal disorderSide effectMass ratio

The invention relates to an osteoblast targeted vector constructed based on a polypeptide. The targeted vector comprises a target head and a support. The target head is the polypeptide. The grafting mass ratio of the target head is 5-10%, and the mole grafting ratio is 2-6%. The targeted vector is prepared by subjecting the polypeptide and a vector to carboxylic acid covalent linking through polyethylene glycol, and is used for filling medicines treating bone fractures, osteoporosis, osteoarthritis, rheumatoid arthritis or tumor bone metastasis. Compared with the prior art, the targeted vector has osteoblast targeting performance, high bone tissue affinity and efficient medicine delivery capability, and is capable of enhancing osteogenesis effects, reducing medicine using amounts, and reducing cell toxicity and side effects. The targeted vector provides an important medicine delivery tool for future osteoporosis treatment.

Owner:TONGJI UNIV

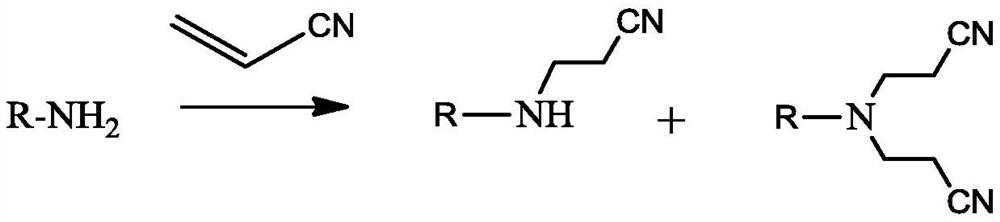

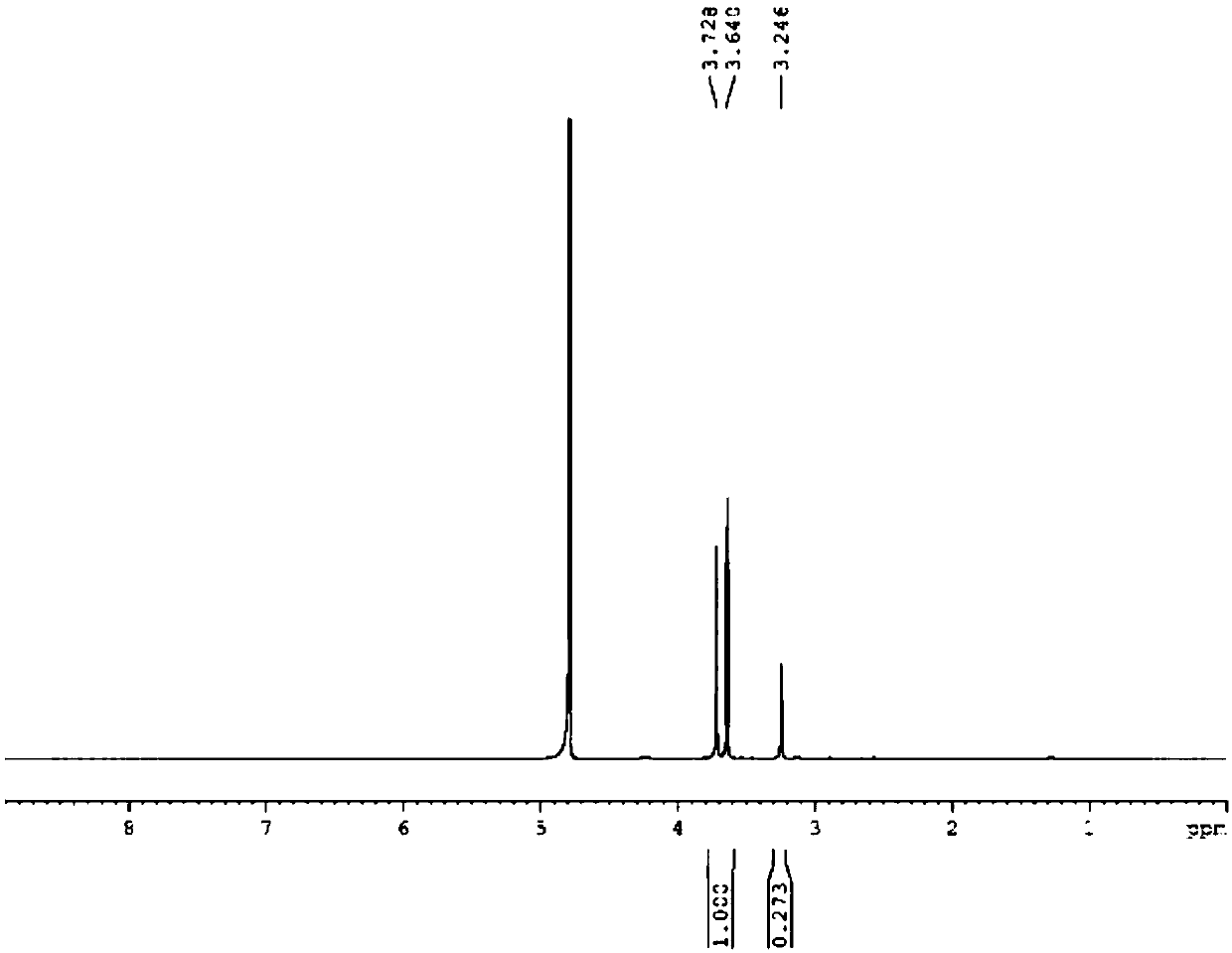

Method for synthesizing dinitrile ethyl tertiary amine from aliphatic primary amine by one-step method

ActiveCN113372241AWeak corrosiveNo need for increased investmentCarboxylic acid nitrile preparationOrganic compound preparationPtru catalystDistillation

The invention provides a method for synthesizing dinitrile ethyl tertiary amine from aliphatic primary amine by a one-step method, which comprises the steps of adding aliphatic primary amine into acrylonitrile by using a glycollic acid aqueous solution as a catalyst, synthesizing a dinitrile ethyl tertiary amine compound by a one-step method under heating reflux, and after the reaction is finished, carrying out reduced pressure distillation treatment to remove low-boiling-point components, and obtaining the dinitrile ethyl tertiary amine compound with the yield being higher than 95%. The process provided by the invention has the following advantages: 1) single nitrile ethylation reaction and double nitrile ethylation reaction are carried out at the same time, so that the reaction efficiency is improved; 2) the glycollic acid is weak in acidity and basically has no corrosion to reaction equipment, so that the equipment investment is reduced; and 3) the reaction mother liquor does not need to be neutralized by adding alkali, so that a large amount of salt-containing wastewater is avoided, and the post-treatment process is simplified.

Owner:WANHUA CHEM GRP CO LTD

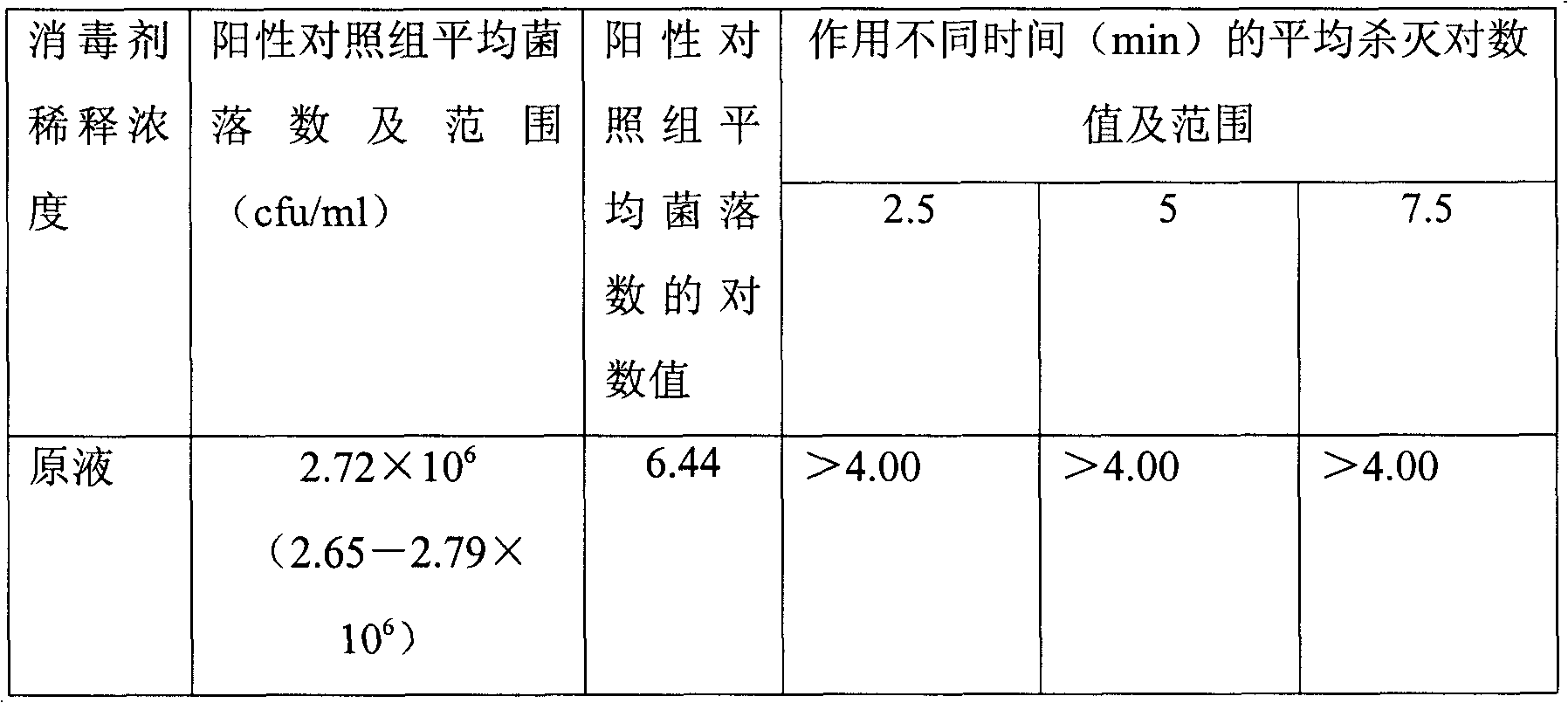

Compound preparation for dissolving staphyloase and preparation method

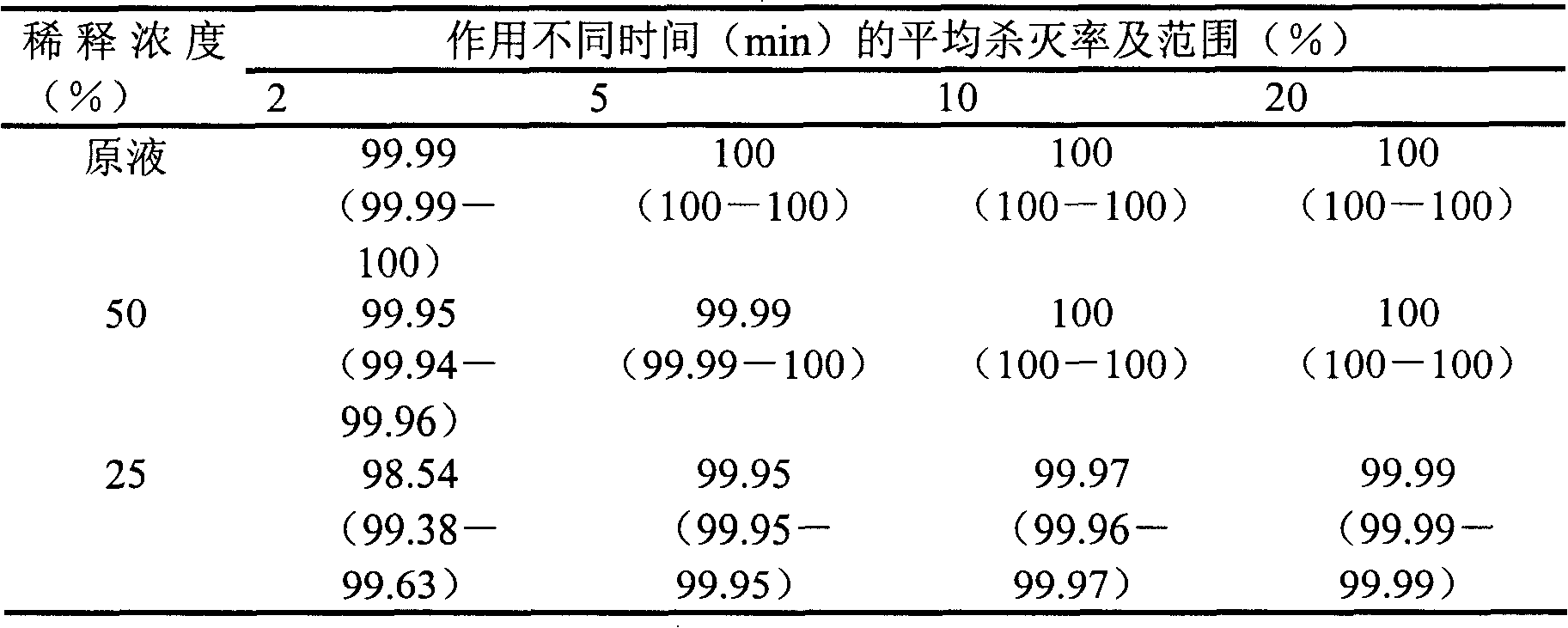

InactiveCN1438032AImprove the bactericidal effectExpanded bactericidal spectrumAntibacterial agentsPeptide/protein ingredientsSide effectMonilinia laxa

The present invention discloses a lysostaphin compounded preparation. Said preparation comprises bacteria-killing effective quantity of lysostaphin and lysozyme. Said lysostaphin compounded preparation has higher bacteria-killing effect as compared with single lysostaphin, not only has the strong bacteria-killing action for Gram-positive bacterium and Gram-negative bacterium, but also has the good effect for killing the fungi of Candida albicans and red trichophyton, etc. It has high bacteria-killing activity and stability, does not produce drug resistance, and has no toxic side effect.

Owner:SHANGHAI HI TECH BIOENG

Mixed surfactant for controlling particle size of fluorine-containing polymer emulsion and method of preparing fluorine-containing polymer therewith

The invention discloses a mixed surfactant for controlling the particle size of a fluorine-containing polymer emulsion and a method of preparing a fluorine-containing polymer therewith. The mixed surfactant is composed of any two or three selected from perfluoropolyether carboxylic acid, perfluoro fatty acid and low-molecular-weight perfluoropolyether. By using the mixed surfactant in water-phase polymerization of the fluorine-containing polymer, the particle size of the fluorine-containing polymer emulsion is controlled to be 50-150 nm and solid content of the emulsion is controlled to be 25-35. In addition, a reaction solution for preparing the fluorine-containing polymer with the mixed surfactant is homogeneous-phase, so that pre-emulsion before polymerization is unnecessary. The mixed surfactant can be applied in a fluorinated monomer emulsion polymerization reaction instead of perfluoroctanoic acid, thereby avoiding the problems of environment pollution, biotoxicity and the like due to usage of the perfluoroctanoic acid.

Owner:ZHEJIANG XINGTENG CHEM

Bactericide for pet and preparation method thereof

InactiveCN101288769AImprove the bactericidal effectExpanded bactericidal spectrumAntibacterial agentsPeptide/protein ingredientsNoseStaphylococcus aureus

The invention discloses a sterilization preparation used for a pet, which includes effective quantity of lysostaphin and lysozyme for the sterilization. The preparation of the invention is provided with higher sterilizing effect than the lysostaphin and a strong function in sterilizing gram-positive bacteria and gram-negative bacteria, especially strong effect in sterilizing resistant staphylococcus aureus. The sterilization preparation has no stimulation to the skin and mucosa of the pet and the drug resistance can not be produced easily. The sterilization preparation provided by the invention can be used for the sterilization and the disinfection of the body parts of the pet, such as the skin mucosa, etc., which is used for cleaning and the disinfection of wounds caused by burning, scalding, scratching, biting, etc., the debridement and the prevention of infection before and after various surgeries of surgery, gynecology, urological department, stomatology, etc. and the cleaning and the disinfection of the oral, the ear canal and the nose of the pet.

Owner:SHANGHAI HI TECH BIOENG

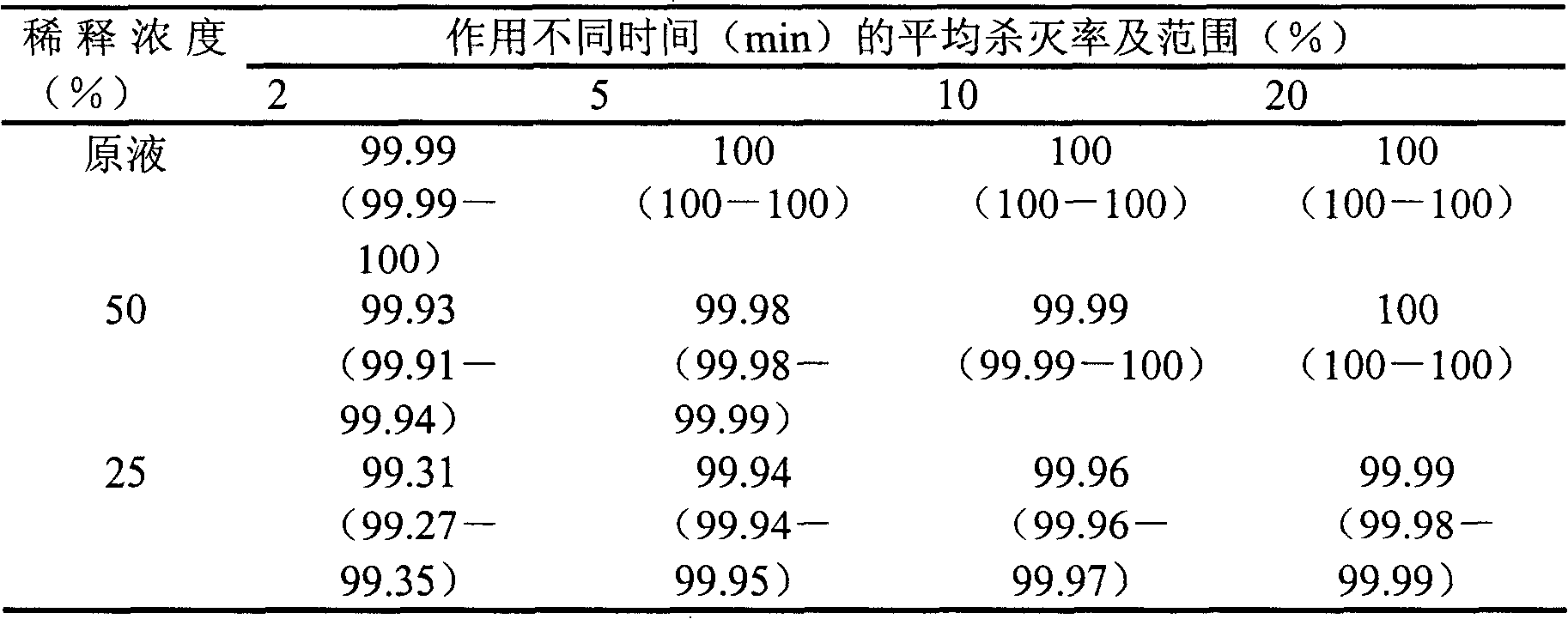

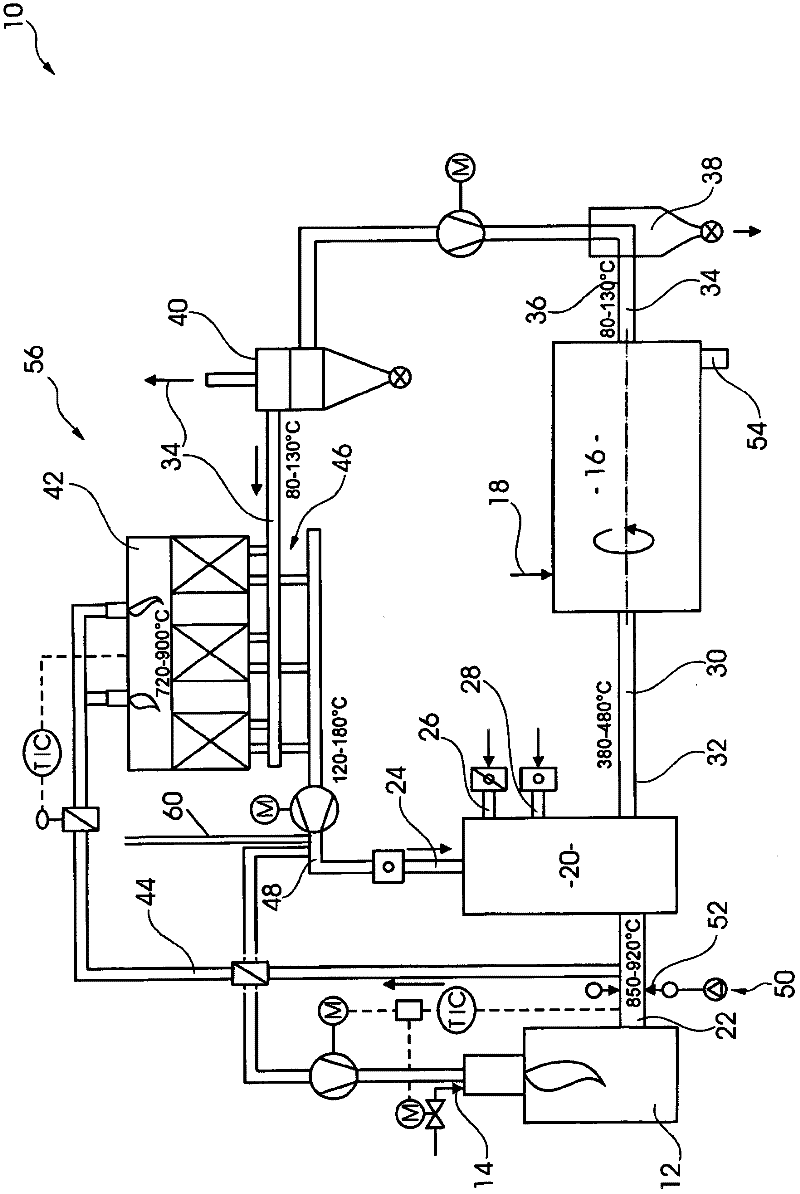

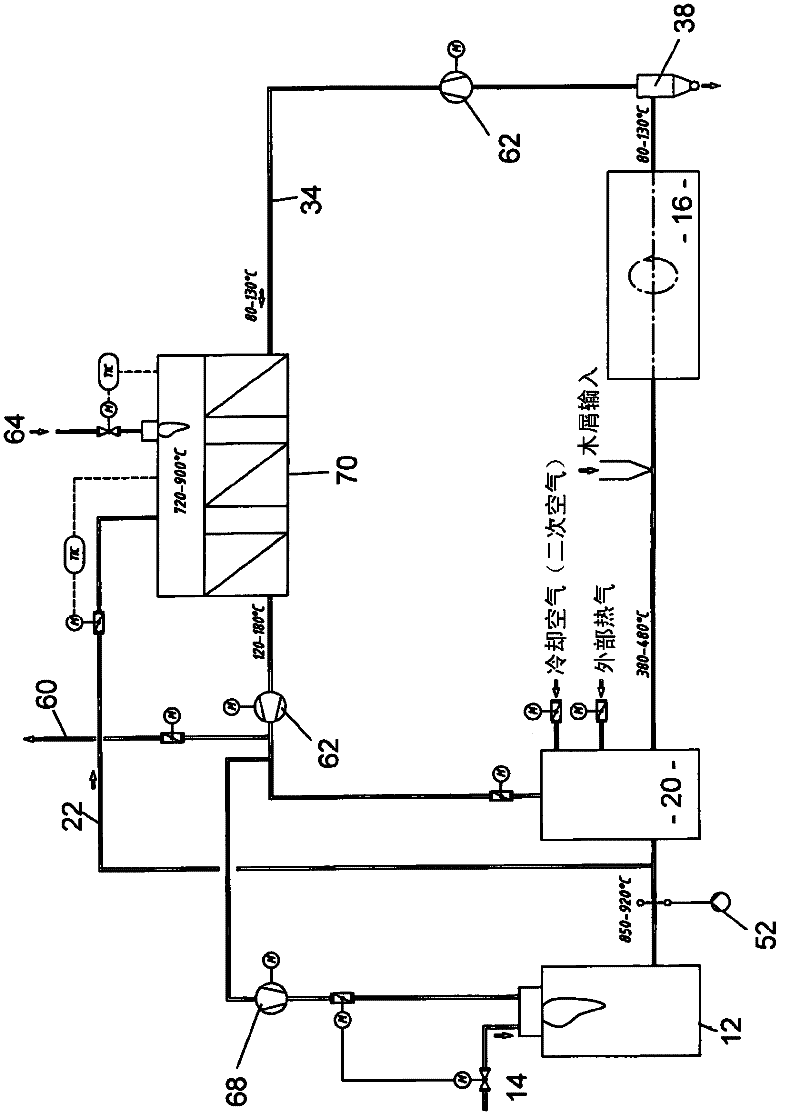

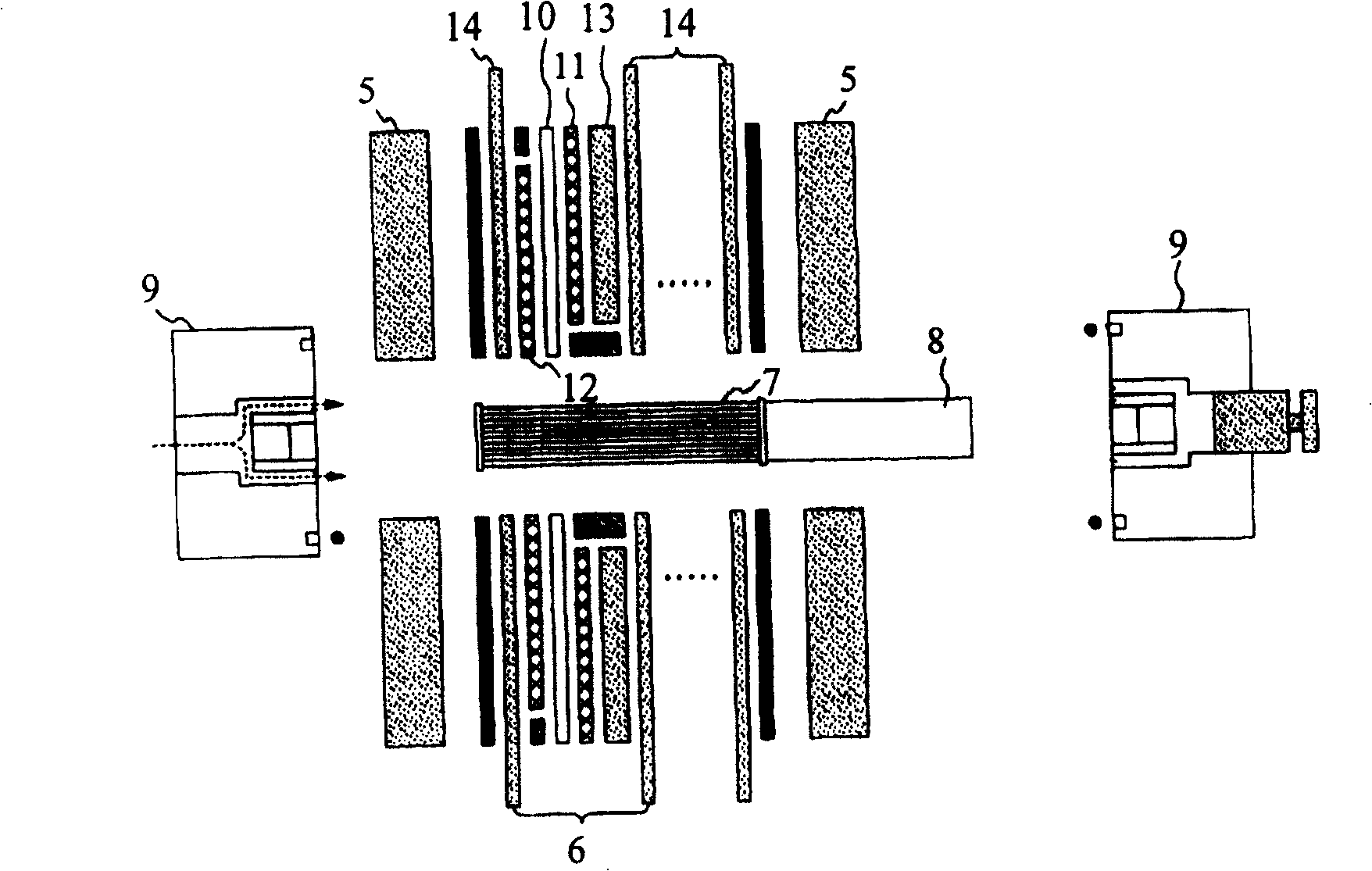

Wood chip drying system for drying wood chip and associated method for drying wood chip

InactiveCN102348949AWill not enrichDrying solid materials with heatDrying gas arrangementsPulp and paper industryOrganic compound

The invention relates to a wood chip drying system for drying wood chip (18) comprising a furnace (12), a drier (16) for the wood chip (18) and a recirculation apparatus (56) for the recirculation of exhaust vapors (34) into the drier (16), wherein the recirculation apparatus (56) has an exhaust vapor heater (42), and wherein the wood chip drying system (10) is designed to reduce organic compounds present in the exhaust vapor (34) prior to the recirculation into the drier (16). The exhaust vapor heater (42) comprises a regenerative and / or catalytic heat exchanger which is arranged downstream after the drier (16) and which is designed so as to heat up the exhaust vapor (34) to a temperature which is high enough to oxidize at least a majority of particles present in the exhaust vapor (34).

Owner:KRONOTEC

Composite feed capable of protecting liver health of tilapia and preparation method of composite feed

InactiveCN105076712AWide variety of sourcesLow priceAnimal feeding stuffAdditive ingredientLithospermum

The invention discloses a composite feed capable of protecting the liver health of tilapia. The composite feed is obtained by mixing Chinese herbal medicine extracts and basic ingredients, and drying the mixture, wherein the weight ratio of the basic ingredients to the Chinese herbal medicine extracts is (995 to 999): (1-5); each 1 to 5 L of the Chinese herbal medicine extracts is obtained by conducting water extraction on the following Chinese herbal medicine: 2 to 10 g of panax notoginseng, 3 to 15 g of shizandra berry, 5 to 20 g of astragalus membranaceus,5 to 15 g of liquorice, 2 to 10 g of radix notoginseng, 6 to 18 g of lithospermum, 5 to 15 g of silybum marianum, and 2 to 10 g of fructus psoraleae. The composite feed is used for tilapia culture, can be used for protecting the liver health of tilapia, and improves the non-specific immunity of the organism of tilapia. The invention further provides a preparation method of the composite feed.

Owner:TONGWEI

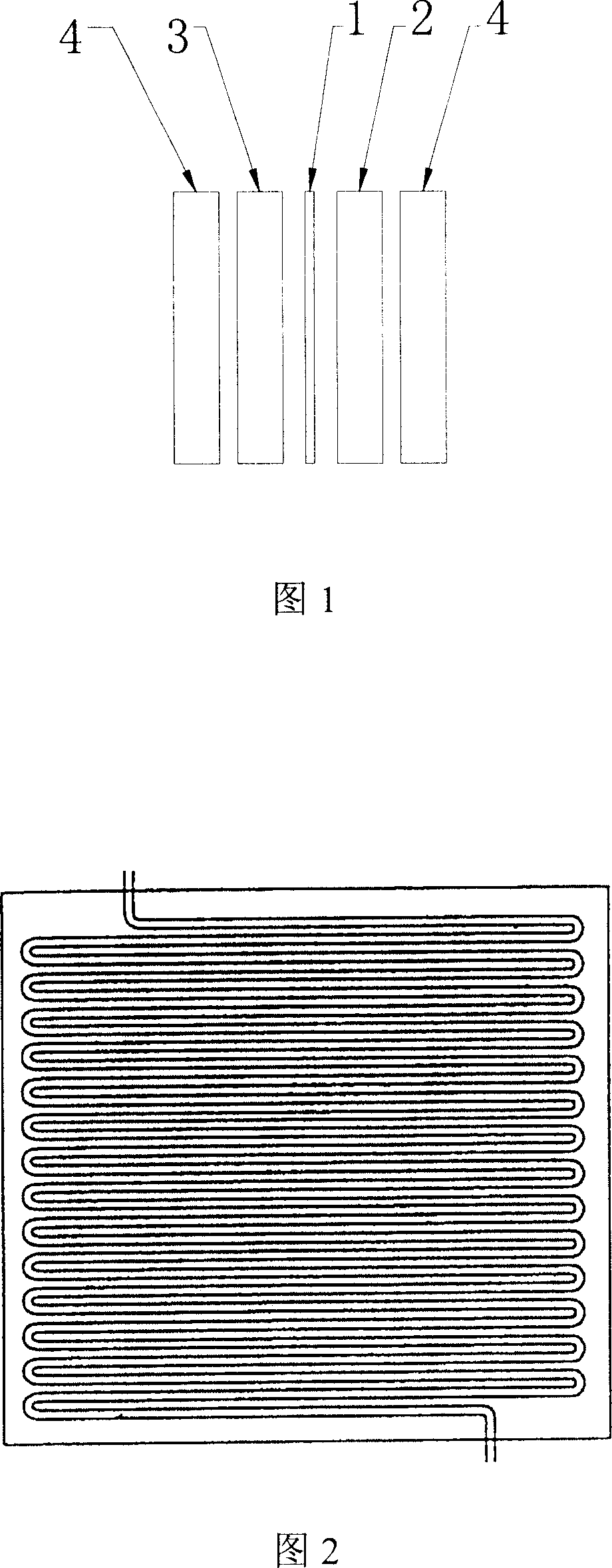

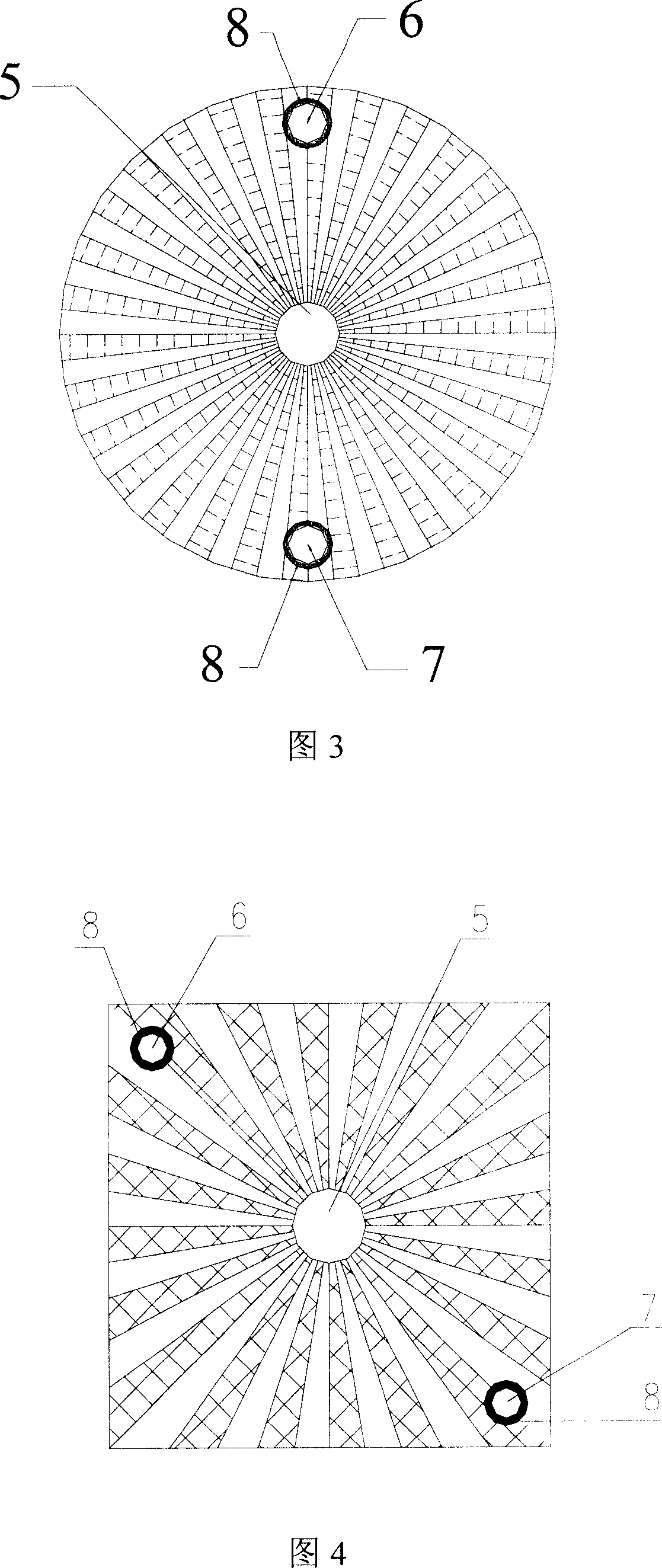

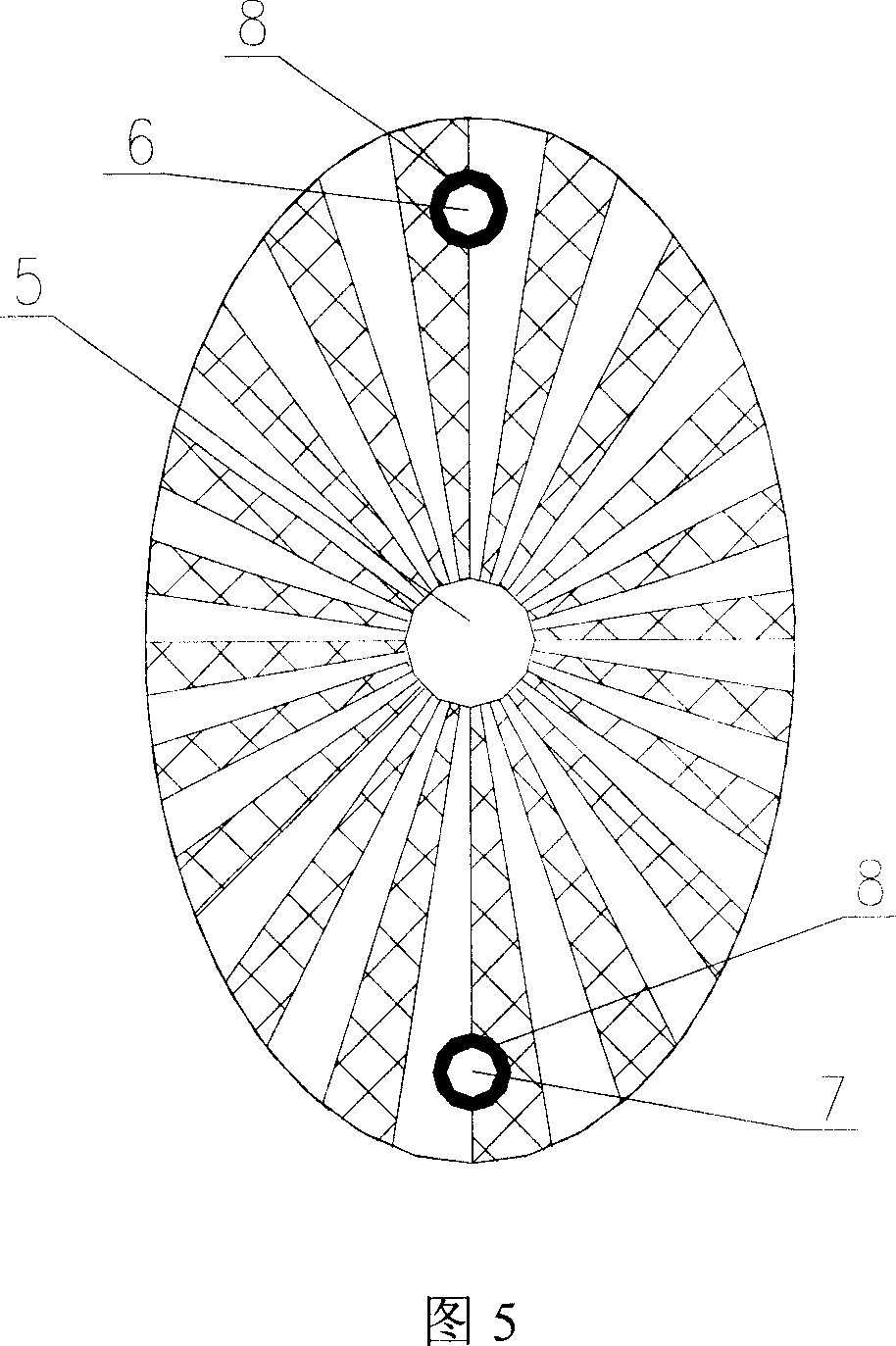

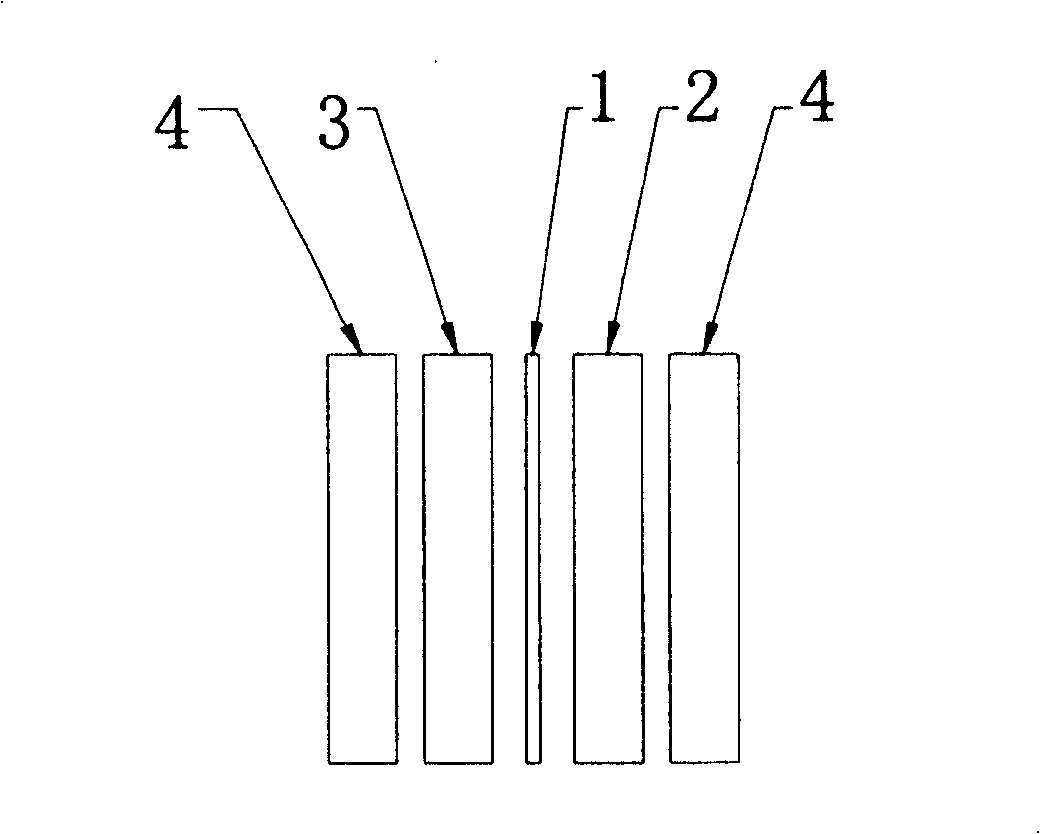

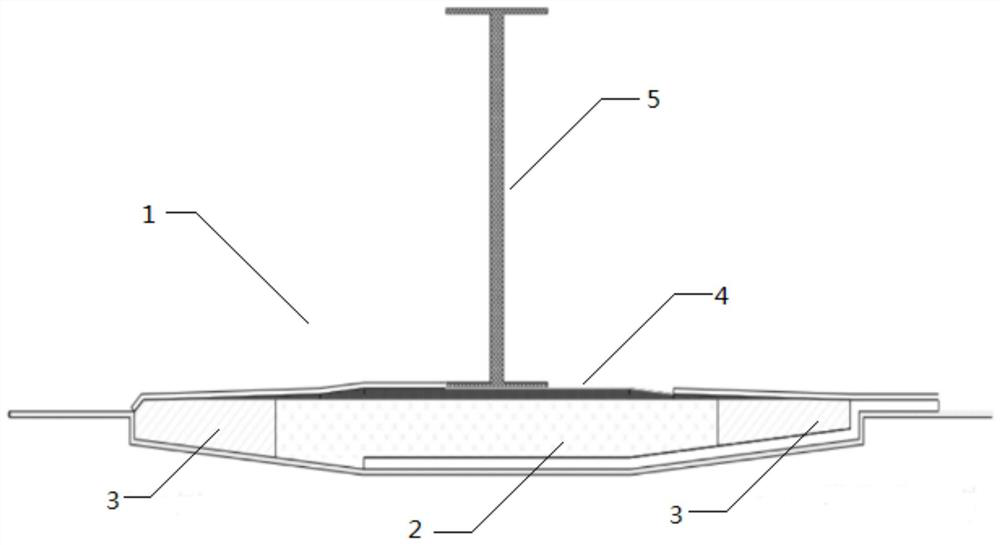

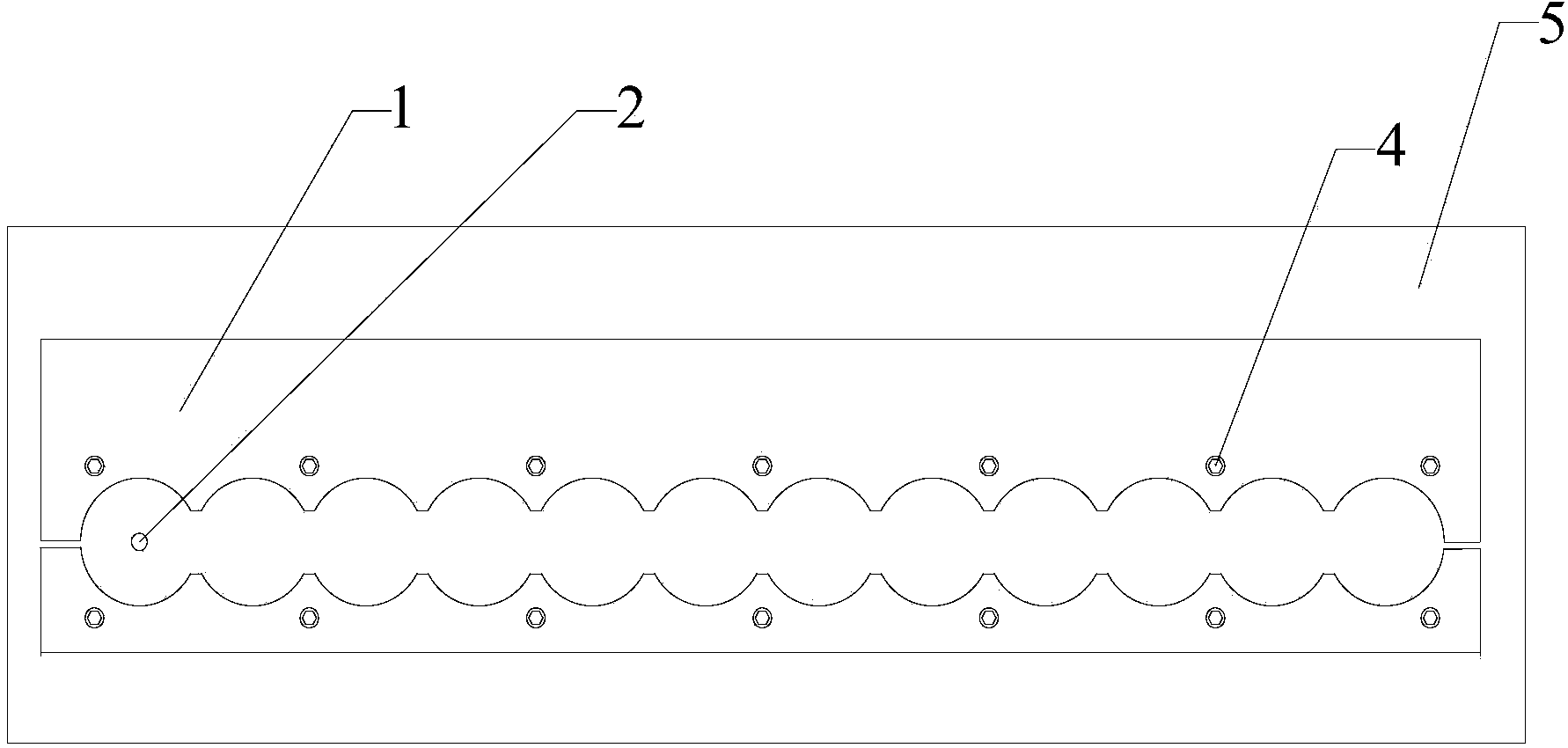

A flow field plate and fuel cell stack containing the same

InactiveCN1953256AShort processFacilitated DiffusionCell electrodesCollectors/separatorsFuel cellsNitrogen

The invention relates to a flow field plate and relative fluid accumulator. Wherein, said flow field plate comprises a central hole at the middle of plate, an inlet and an outlet (6, 7) at two positions near the edge of plate; one surface of it comprises divert groove radiated from the central hole (5) to circumstance. Since the plate has radiated divert groove with short length, the reaction agent can be dispersed easily, to avoid dead area, to flow into any part of flow, and the generated material as water, nitrogen, etc, can be discharged on time, to improve the utilization of reaction agent.

Owner:BYD CO LTD

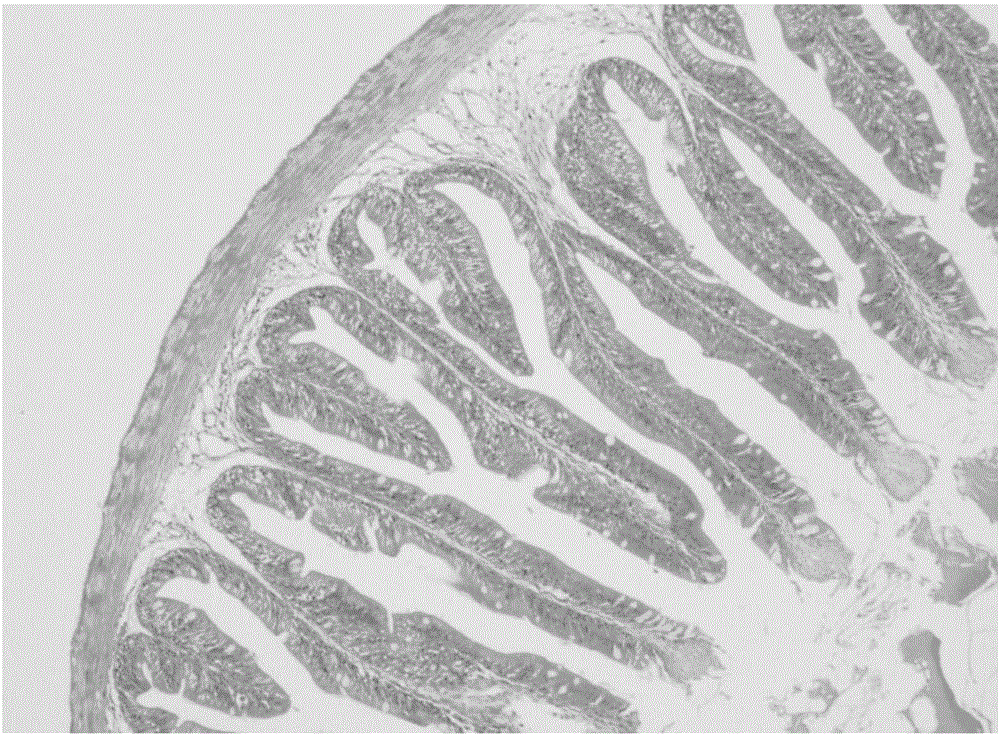

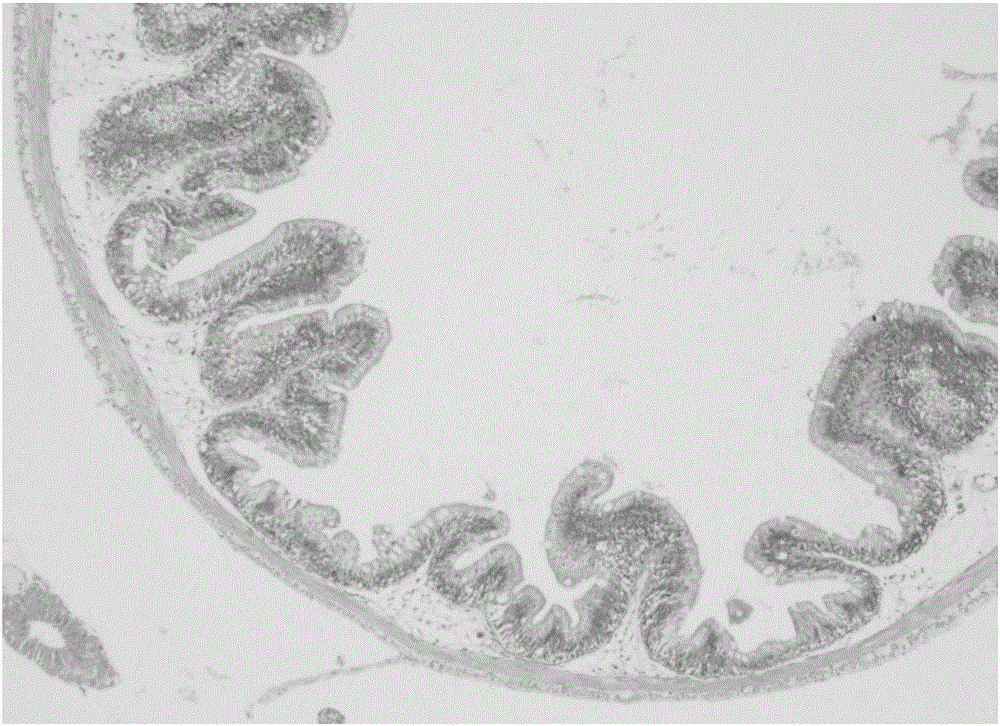

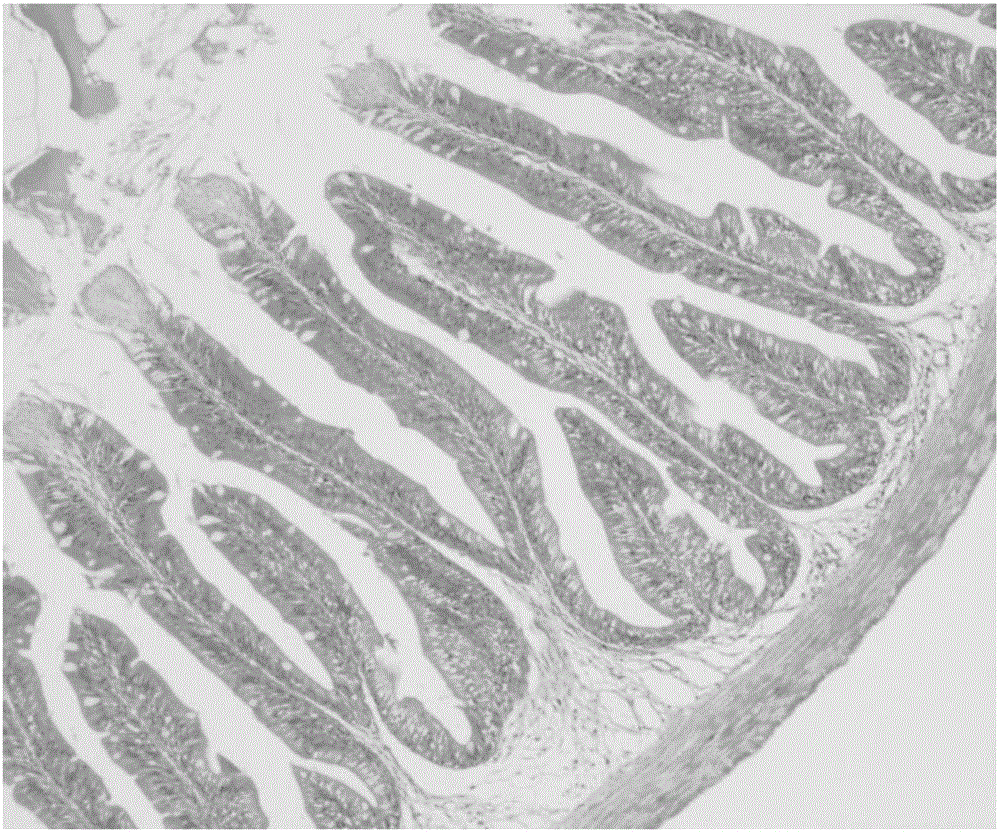

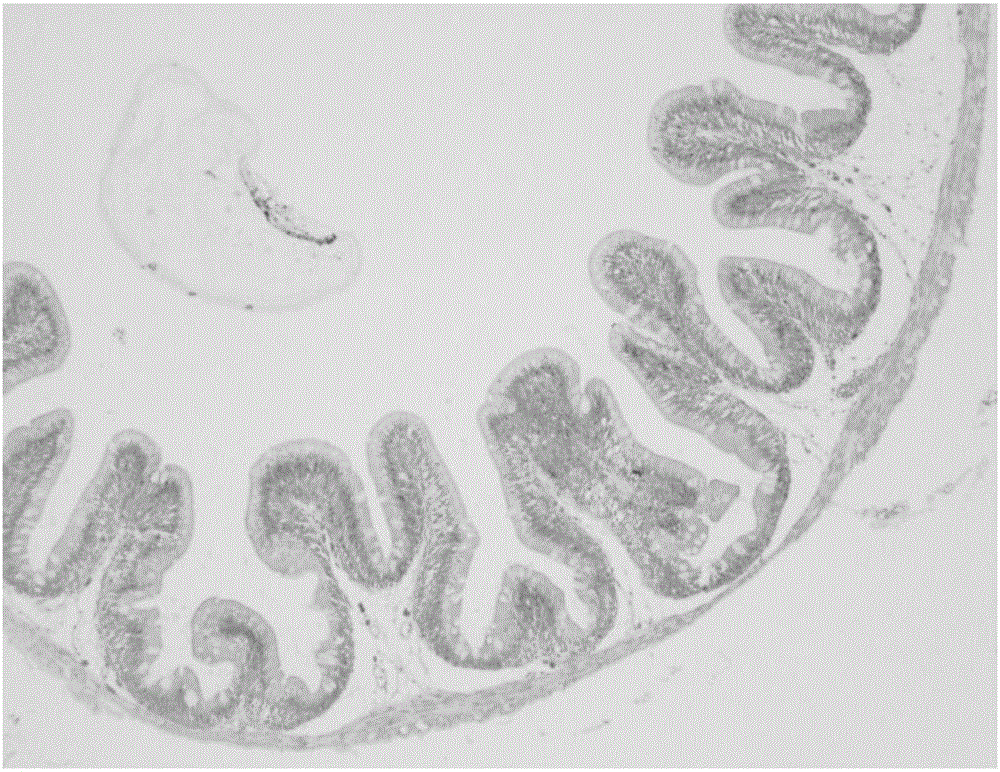

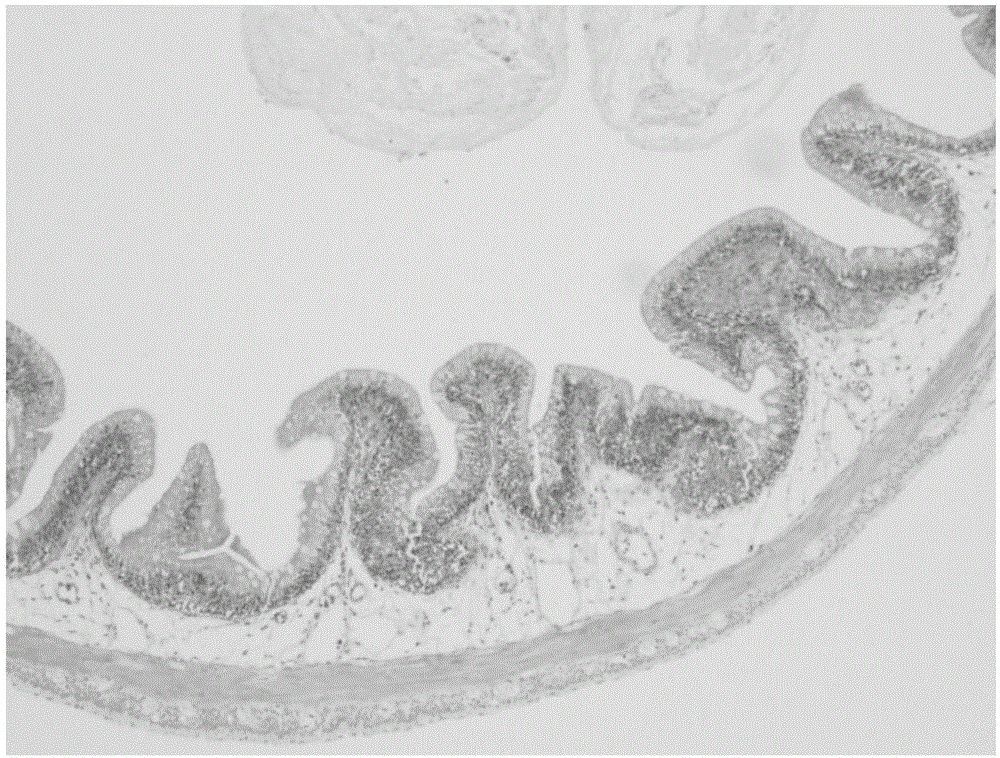

Compound feed capable of improving intestinal tract health of channel catfish and preparation method of compound feed

InactiveCN106333148AEasy to addNo pollutionFood processingDigestive systemLiver tissueIctalurus catus

The invention provides compound feed capable of improving intestinal tract health of channel catfish. The compound feed is prepared by mixing and drying a Chinese herbal extract and a basic component, wherein the weight ratio of the basic component to the Chinese herbal extract is (995-998): (2-5); each 2-5kg of Chinese herbal extract is prepared from the following Chinese herbal components through water extraction: 5-15g of pseudoginseng, 10-25g of dandelion, 10-30g of astragalus membranaceus, 10-25g of coptis chinensis, 10-30g of liquorice, 10-25g of perila seed, 10-30g of rheum officinale and 20-50g of garlic. The compound feed can improve health of the intestinal tract and a liver tissue, improve the intestinal immune function, maintain the stability of intestinal flora and prevent intussusception of the channel catfish; meanwhile, the invention further provides the compound feed prepared by the preparation method. The invention relates to the technical field of aquatic feed.

Owner:TONGWEI

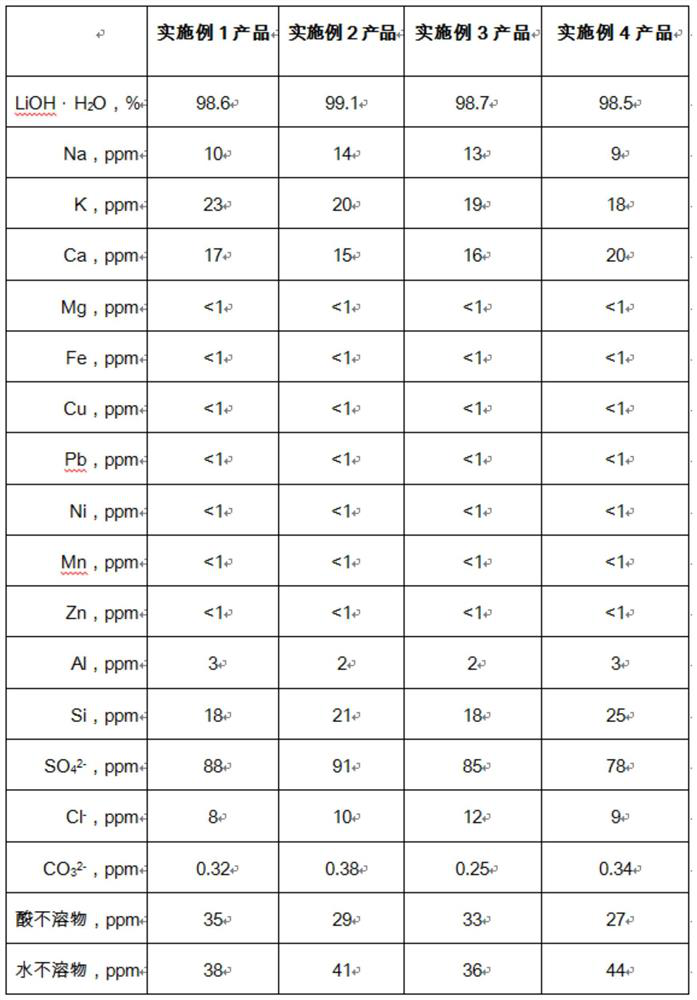

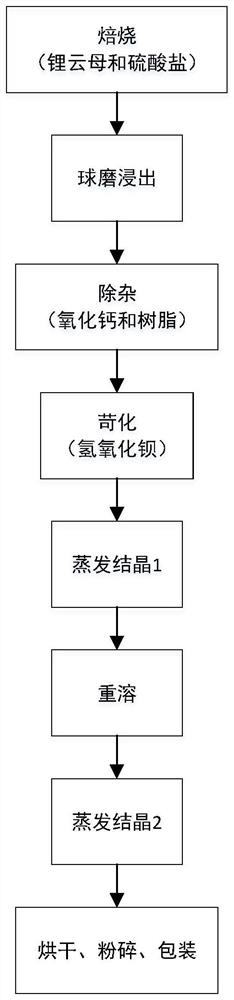

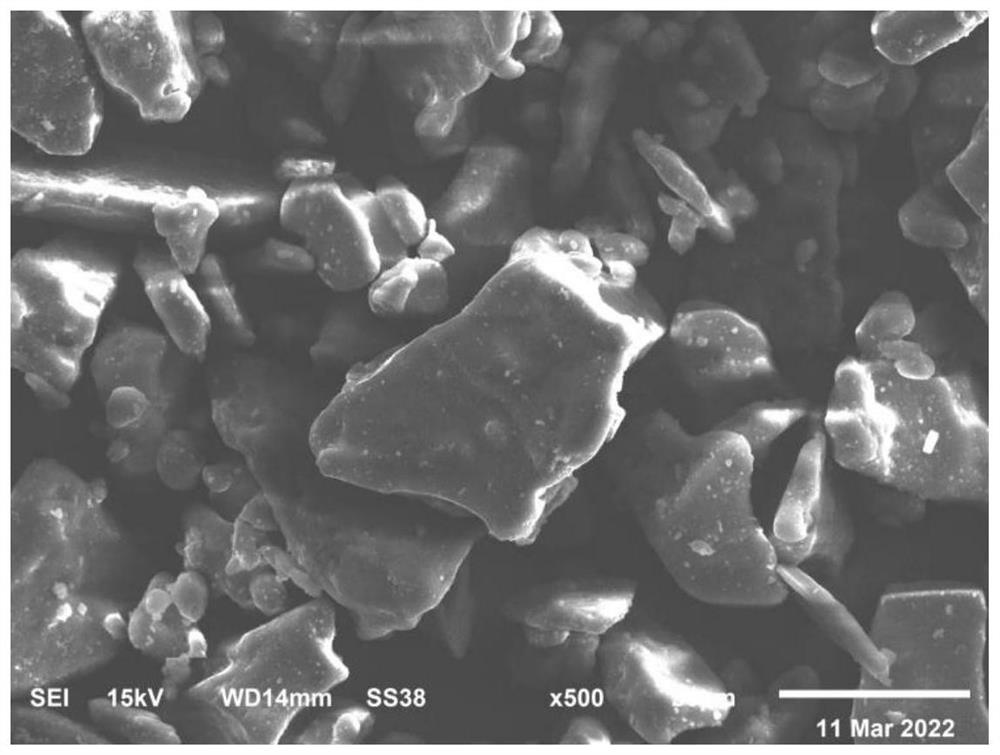

Process method of micro-powder battery grade lithium hydroxide monohydrate

PendingCN114538480ASimple preparation processReduce manufacturing costCalcium/strontium/barium sulfatesLithium oxides/hydroxidesIon exchangeLithium carbonate

The invention discloses a process method of micro-powder battery grade lithium hydroxide monohydrate. Comprising the following treatment steps: mixing lepidolite and sulfate, roasting, adding water, ball-milling and leaching, carrying out liquid-solid separation, adding calcium oxide to adjust the pH value, carrying out liquid-solid separation, removing cations such as calcium and magnesium by using ion exchange resin, causticizing barium hydroxide, crystallizing, re-dissolving, crystallizing and drying, crushing, packaging and the like. According to the process method of the micro-powder battery-grade lithium hydroxide monohydrate, the process step of obtaining the lithium hydroxide monohydrate from the lepidolite ore is reduced, and meanwhile, other lithium salt processes such as lithium carbonate precipitation and the like are not needed in the process to convert the lithium hydroxide into lithium hydroxide; the lithium hydroxide monohydrate preparation process is simplified, the production cost is reduced, the product quality stability is improved, and the product yield is improved.

Owner:江西九岭锂业股份有限公司

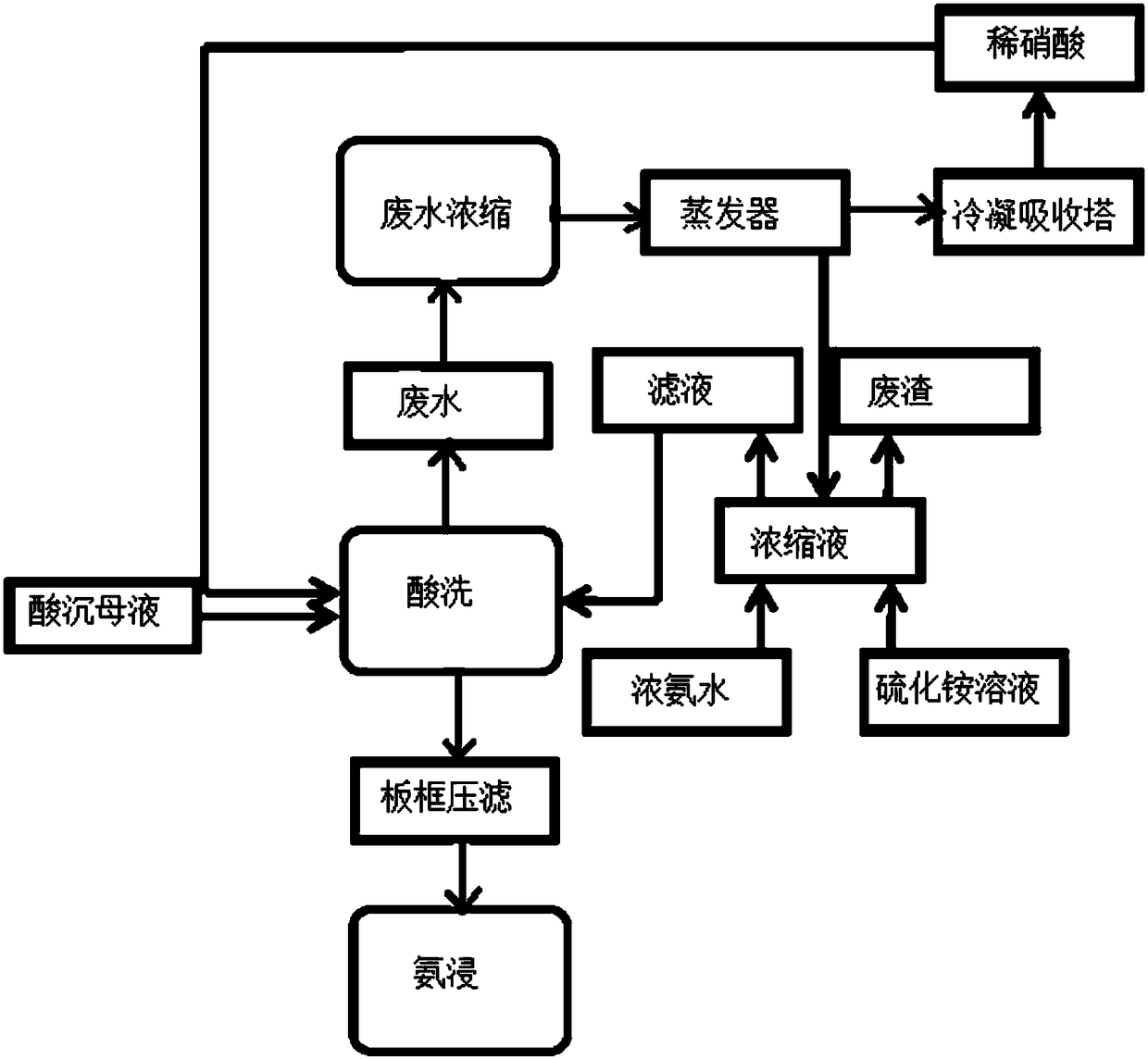

Production process for treating ammonia-nitrogen wastewater

ActiveCN108128958ASimple and fast operationWill not enrichWater contaminantsTreatment involving filtrationProduction lineAmmonia nitrogen

The invention discloses a production process for treating ammonia-nitrogen wastewater. By adopting a mode that concentrated wastewater is heated and evaporated, and a precipitant is added to remove most cation and anion in a liquid in a cooling crystallization mode, ions in a circulated solution cannot be enriched, advantages of an acid salt pretreatment process in ammonium molybdate production are ensured, the problem that wastewater of a conventional ammonium molybdate production line is hard to treat is solved, and the production process has the characteristics of zero wastewater emission,circulation utilization and environmental protection.

Owner:JINDUICHENG MOLYBDENUM CO LTD

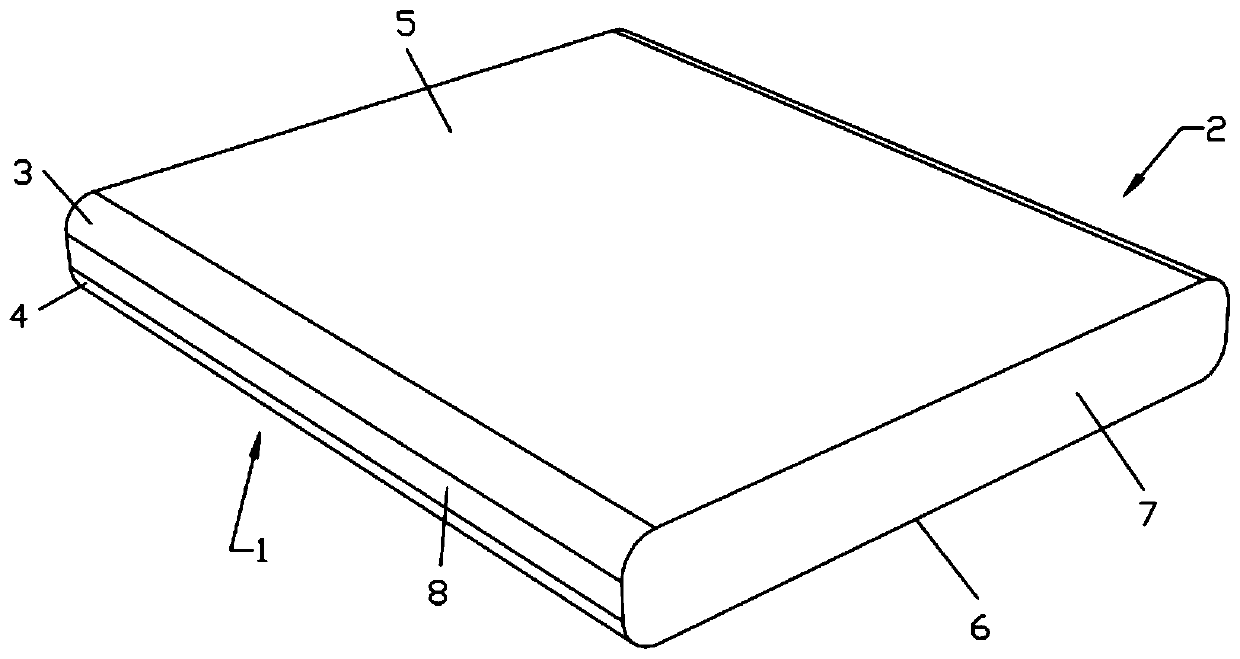

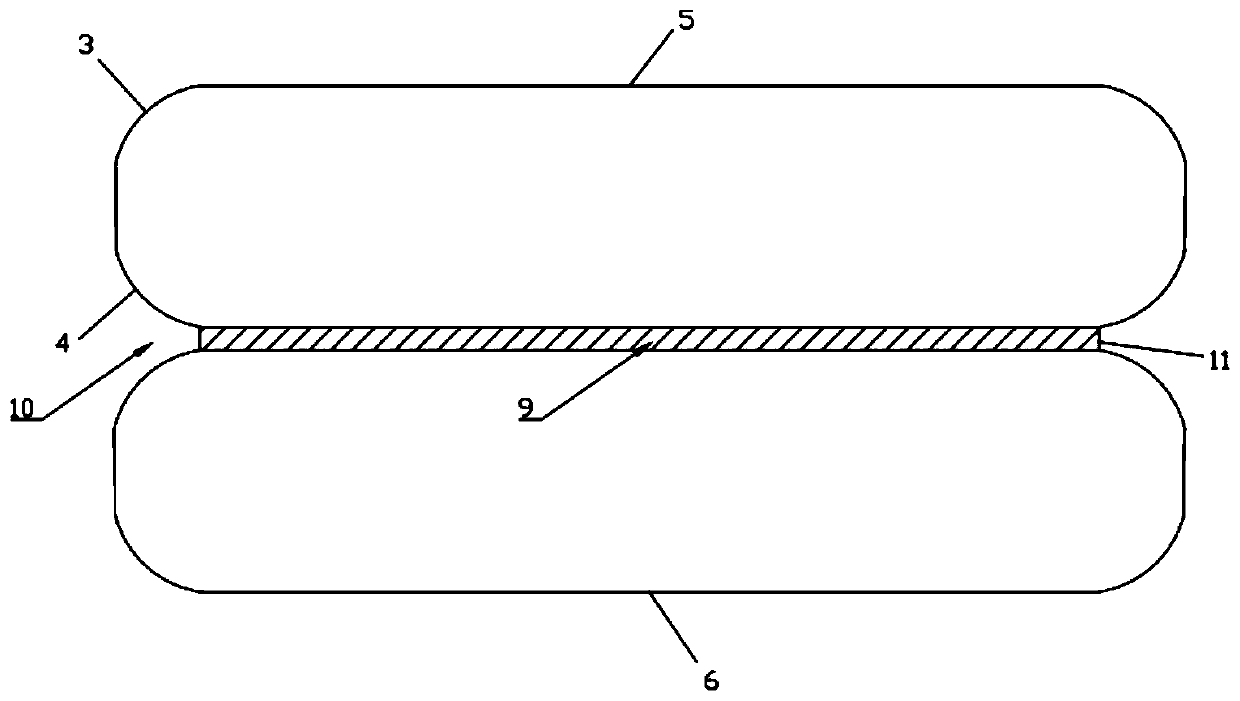

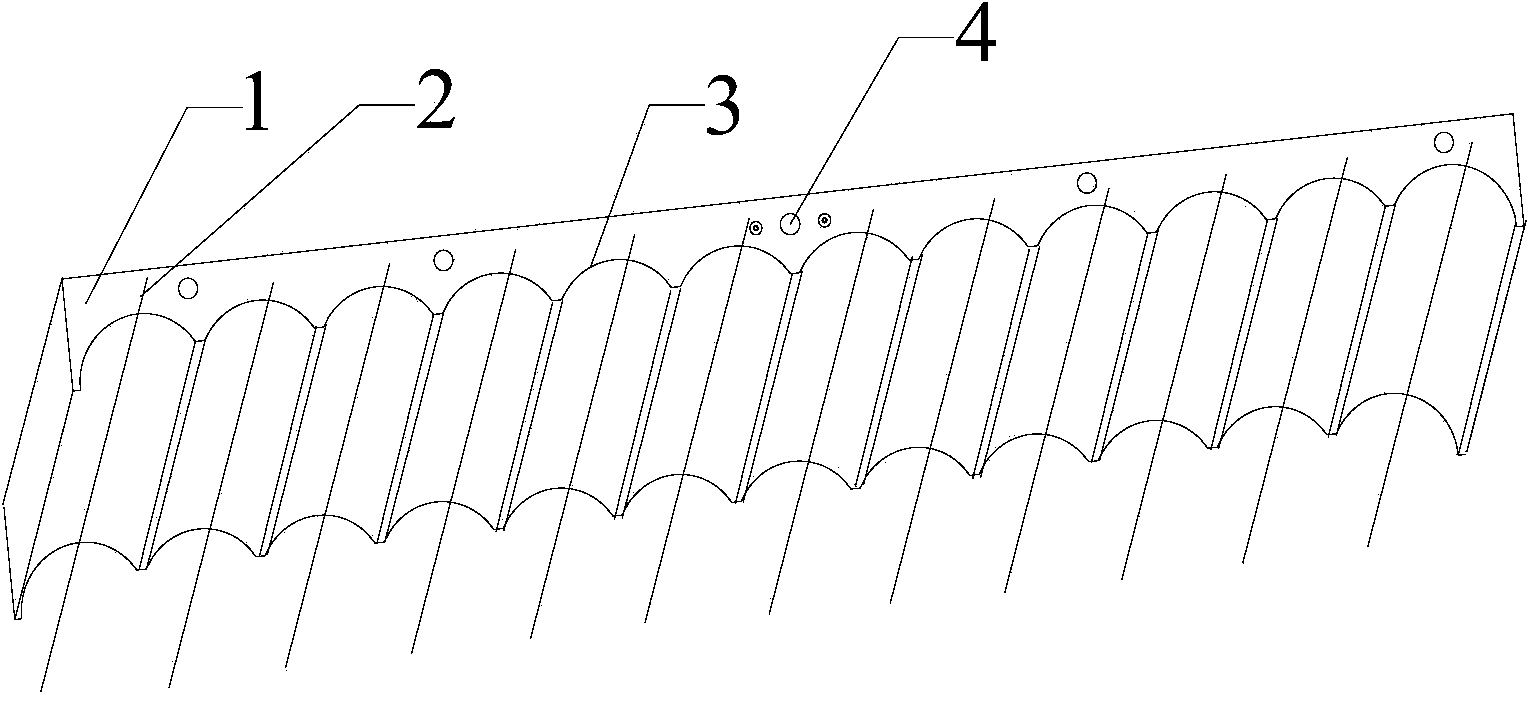

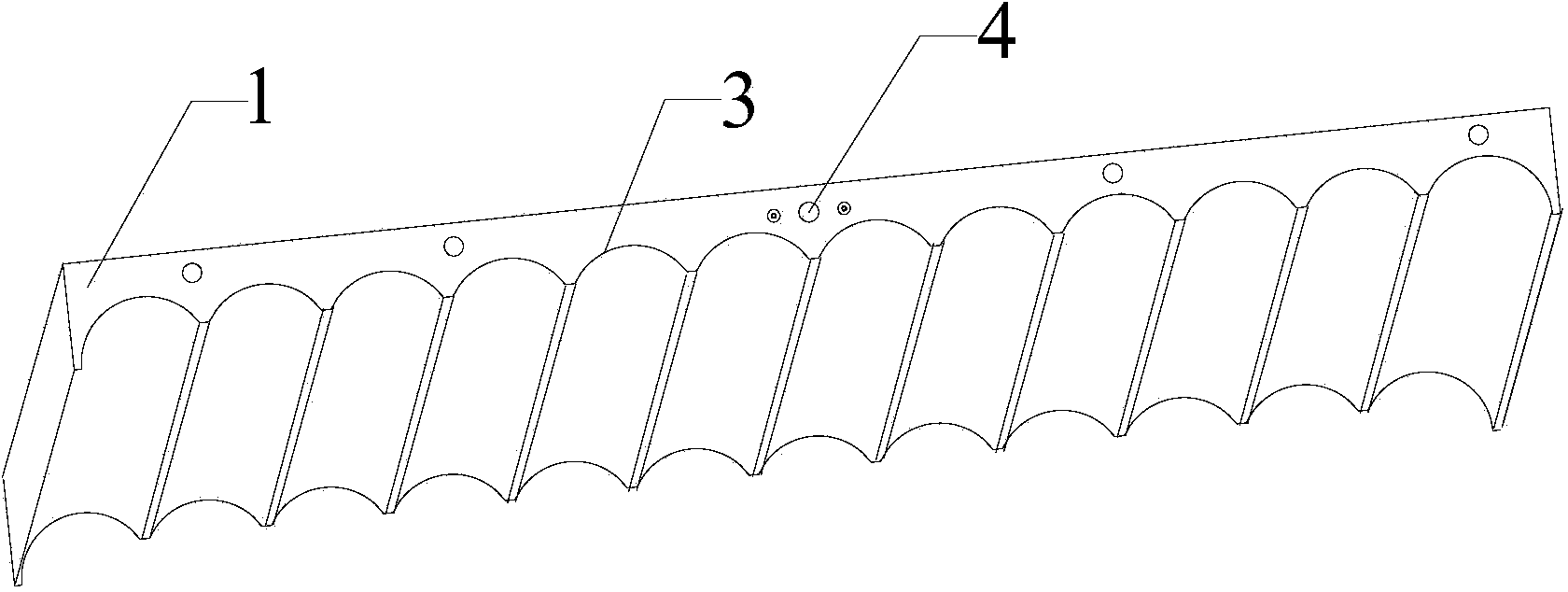

Method for manufacturing spar cap for wind turbine blade

The invention discloses a method for manufacturing a beam cap for a wind turbine blade, and relates to the technical field of wind turbine manufacturing. The method comprises the following steps thata plurality of fiber plates are provided, each fiber plate is provided with a first side part and a second side part which are arranged opposite to each other and extend in the longitudinal direction,the first side part comprise a first arc-shaped surface and a second arc-shaped surface, and the second side part comprise another first arc-shaped surface and another second arc-shaped surface; theplurality of fiber plates are stacked in a mold in the vertical direction; the outer surface of the stacked fiber plates is coated with a layer of vacuum film, and after coating is finished, vacuum areas are formed among the fiber plates; a vacuum pump is used for vacuumizing; resin is supplied; and all the fiber plates are combined together by curing the resin. According to the method for manufacturing the beam cap of the wind turbine blade, in the width direction of the plate, the two sides are processed into round corners, so that the resin cannot be gathered and can sufficiently flow, so that the purpose of full infiltration is achieved, and the bonding strength among the plates is improved.

Owner:上伟(江苏)碳纤复合材料有限公司

Continuous casting process of steel for high titanium alloy welding rods

The invention relates to a continuous casting process of the metallurgy field and discloses a continuous casting process of steel for high titanium alloy welding rods. Full protection pouring is used during continuous casting, and long nozzle argon sealing protection pouring is used from a steel ladle to an intermediate ladle. The whole built-in submersed nozzle protection pouring is used from the intermediate ladle to a crystallizer. A covering agent is used by molten steel in the intermediate ladle. The electromagnetic stirring is used in the process of continuous casting and pouring. Full automation liquid level detection is carried out on the liquid level of the crystallizer. The continuous casting pulling speed is controlled automatically according to the degree of superheat of the intermediate ladle. The degree of superheat of the intermediate ladle in a first continuous casting and pouring furnace is controlled at 30-40 degrees centigrade. The pouring pulling speed is controlled in a range of 1.8-2.4 m / min. The protection slag is composed of the following components measured in percentage by weight: 0.80 + / - 0.15% of R, 35.0 + / - 3.5% of SiO2, 28.0 + / - 3.5% of CaO, less thanor equal to 5.0% of Al2O3, less than or equal to 4.0% of Fe2O3, less than or equal to 5.0% of MgO, 4.5 + / - 1.5% of F<->, 5.0 + / - 2.0% of K2O + Na2O and 12.0 + / - 2.5% of solid C. According to the continuous casting process, the molten steel is prevented from second oxidization in the process of pouring effectively; the stability of titanium in the molten steel is ensured; protection slag is prevented from denaturing; and the quality of the surface of a casting blank is enhanced.

Owner:NANJING IRON & STEEL CO LTD

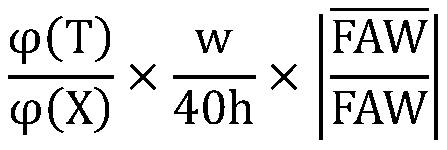

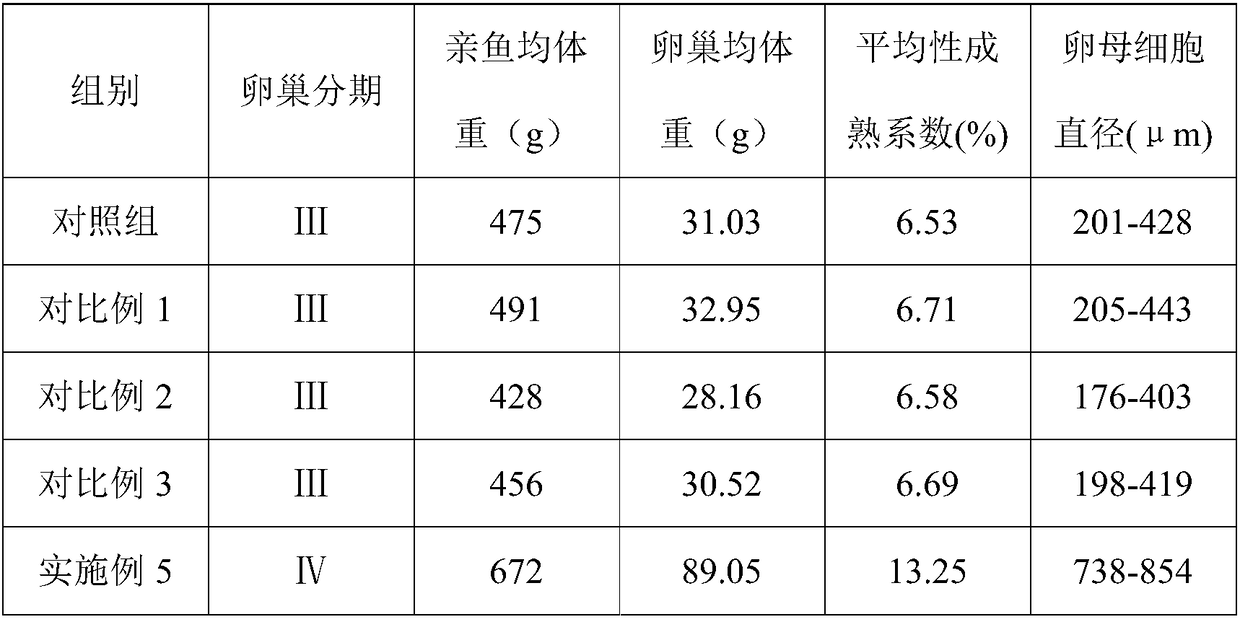

Special dace feed as well as preparation method and application thereof

The invention discloses a special dace feed as well as a preparation method and application thereof. The special dace feed comprises the following raw materials in parts by weight: 5-12 parts of cuttlefish internal organ paste, 1-5 parts of fish oil, 18-26 parts of fish meal, 11-19 parts of areca peel and 23-31 parts of hibiscus mutabilis. The raw materials used for the special dace feed are environmental-friendly, free from toxic and harmful effects, broad in sources, low in price and easy to obtain; the preparation method is simple and is easy in industrialized production; when the special dace feed is used for raising parent daces, the effects of being free form residues, free from enrichment and free from pollution to breeding water bodies are achieved. In addition, the special dace feed also has the functions of promoting growth and enhancing immunity, and has higher social benefits and higher economic benefits. The special dace feed disclosed by the invention can strengthen the combination of sex hormones with target organs, so that the propagation capacity of parent daces is improved, the egg diameter and the sexual gland index of the parent daces can be enlarged, and the fertilization rate and the fry emergence rate of the parent daces can be substantially increased.

Owner:福州海汇生物科技实业有限公司

Feed capable of improving immunity of sheep

InactiveCN106615751AInhibitionAvoid spreadingFood processingAnimal feeding stuffDiseaseBiotechnology

The invention discloses a feed capable of improving the immunity of sheep. The feed is prepared from the following raw materials in parts by weight: 20-40 parts of sweet potato powder, 10-20 parts of corn germ, 20-30 parts of oat bran, 5-15 parts of swelling soya dregs, 25-45 parts of sunflower seed meal, 6-12 parts of fermented feather meal, 2-4 parts of bean worm powder, 5-13 parts of housefly protein, 8-16 parts of potato protein, 4-8 parts of rice bran oil, 3-7 parts of peanut oil, 1-2 parts of montmorillonite, 0.6-1.2 parts of monocalcium phosphate, 0.4-0.8 part of vitamin A, 0.3-0.5 part of vitamin E, 2-4 parts of choline chloride, 0.4-0.8 part of glycine betaine and 2-6 parts of Chinese herbal medicines. Occurrence and transmission of infectious diseases are effectively inhibited, and meanwhile, the feed has the effects of helping digestion, relieving stasis, benefiting qi, nourishing blood, expelling parasite, inhibiting bacteria and resisting diseases, and the immunity of a sheep body can be effectively strengthened.

Owner:定远县仓镇恒润养殖专业合作社

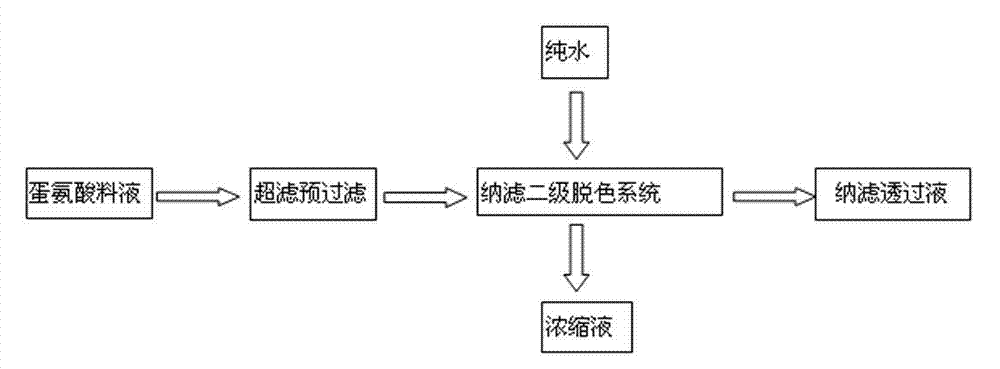

Method for decoloring methionine crystallization mother liquor by adopting membrane integration technology

InactiveCN104844487AReduce turbidityPurify and refineOrganic chemistryOrganic compound preparationHigh concentrationUltrafiltration

The invention provides a method for decoloring a methionine crystallization mother liquor by adopting a membrane integration technology. The method comprises the following steps: 1, carrying out ultrafiltration (UF) system treatment on methionine; and 2, carrying out nanofiltration (NF) membrane decoloring purification system treatment, adding pure water to the obtained nanofiltration concentrate, carrying out filter washing, directly conveying the obtained substance to a burning device, burning, and allowing an NF permeation liquid to directly enter a subsequent process. The clean production membrane integration decoloring technology is adopted to substitute active carbon decoloring in order to remove colloids and other pigments in the methionine crystallization mother liquor, so the generation of solid wastes of an enterprise is reduced, and the working environment of a decoloring workshop is improved; and high concentration multiple of the membrane technology is used, so the emission amount of wastewater is reduced, and the running pressure of the wastewater treatment station of the enterprise is reduced.

Owner:HANGZHOU BLUETEC ENVIRONMENTAL TECH

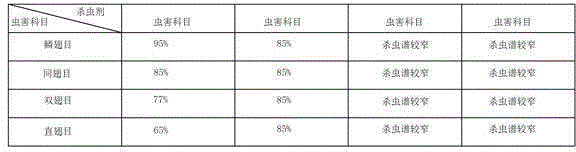

Special plant source insecticide for rice and preparation method for special plant source insecticide for rice

The invention relates to a special plant source insecticide for rice and a preparation method for the special plant source insecticide for rice. The preparation method for the special plant source insecticide for rice comprises a preparation process of master batch and a preventive insecticide and an emergent insecticide, a synthetic method for the preventive insecticide and a synthetic method for the emergent insecticide. By virtue of alkalization of raw materials and three-stage crushing, an alkaloid pure product is no longer deliberately extracted. According to the technical scheme, zero emission on the whole course is realized by virtue of simple and cheap treatment equipment without any waste residue discharge and any exhaust gas and wastewater, so that the preparation method is environmental-friendly and obvious in economical benefit. The raw materials of the plant source insecticide are natural plants, and the effective components of the plant source insecticide are natural substances, have a smooth degradation path in nature and are not enriched and are free of residues; the insecticide prepared by taking veratrum nigrum as the raw material has the advantages of being strong in selectivity and low in toxicity to human, livestock and enemies. The technical scheme provided by the invention is of universality, and a fresh veratrum nigrum product, a fresh euphorbia fischeriana product and a fresh artemisia capillaris product can be used for implementing the insecticide according to the technical scheme provided by the invention.

Owner:黑龙江东北亚林产品有限公司

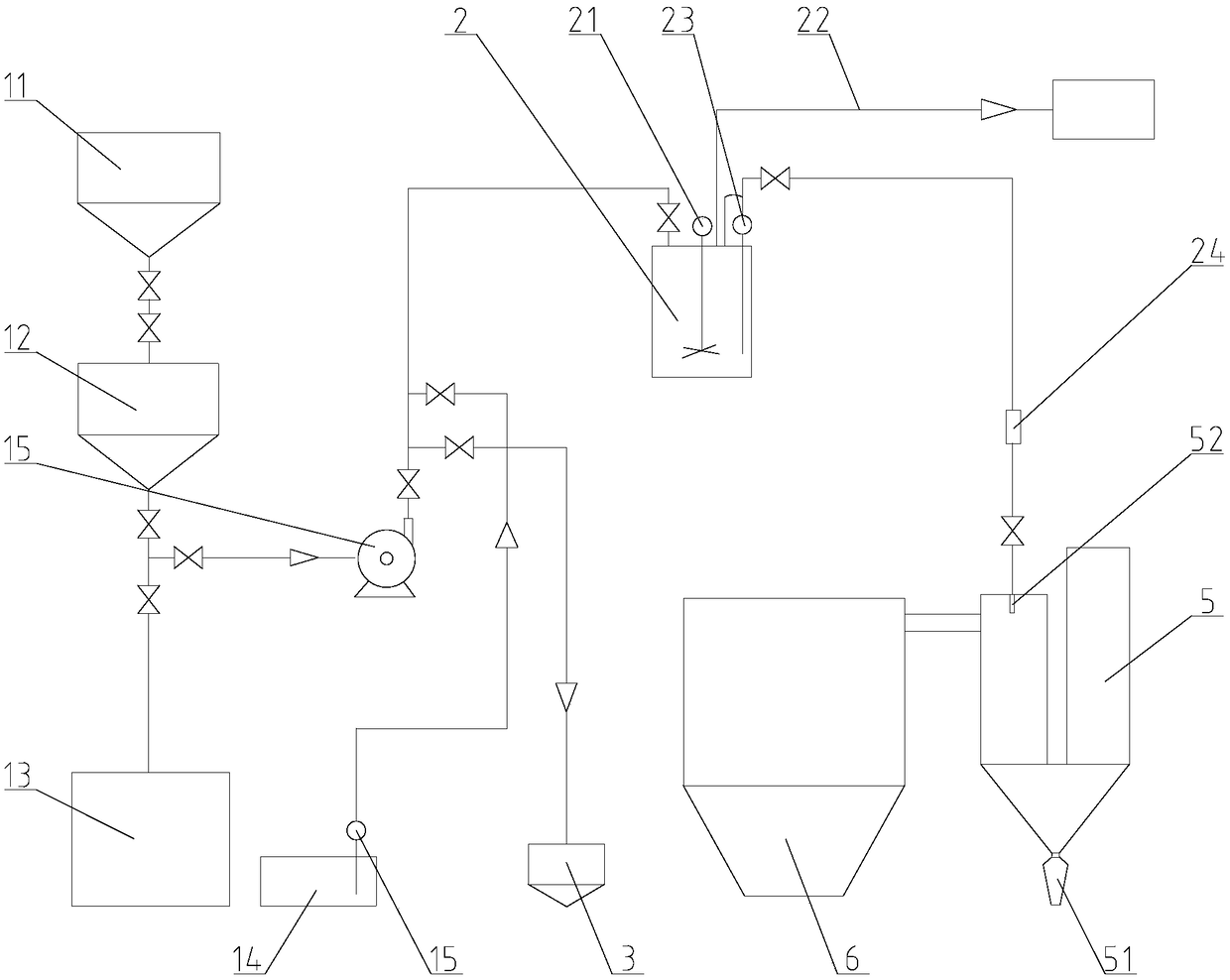

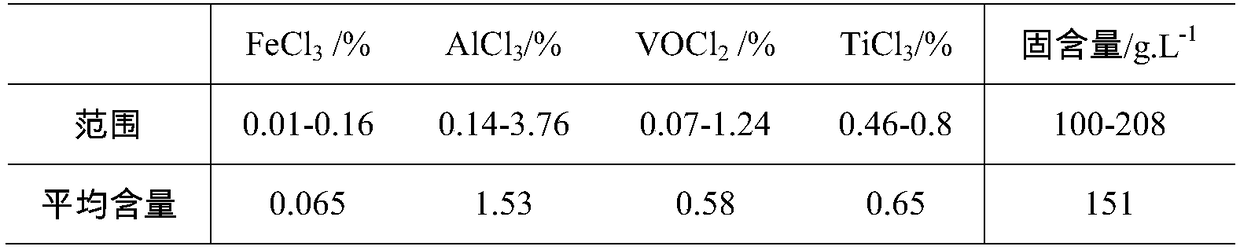

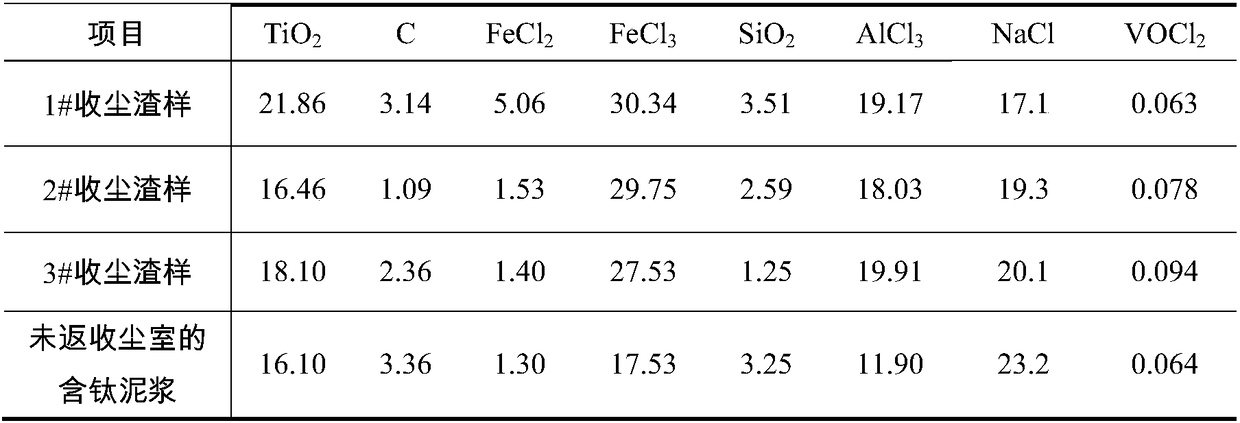

Titanium containing slurry titanium tetrachloride recycling system and recycling method

InactiveCN108996545AStable recyclingEfficient recyclingTitanium tetrachlorideEnergy inputMolten saltSlurry

The invention discloses a titanium containing slurry titanium tetrachloride recycling system, and a recycling method. The titanium containing slurry titanium tetrachloride recycling system comprises acharging assembly, a high position tank, a molten salt chlorination furnace, and a dust collecting chamber; the charging assembly is communicated with the high position tank; the dust collecting chamber is communicated with the molten salt chlorination furnace; the high position tank is arranged above the dust collecting chamber, and is communicated with the dust collecting chamber. The titaniumcontaining slurry titanium tetrachloride recycling system is used for extracting residual high solid impurity content titanium containing slurry from equipment used for producing titanium tetrachloride, stirring the titanium containing slurry, conveying the titanium containing slurry into the molten salt chlorination furnace, generating titanium tetrachloride high temperature smoke with waste heat, realizing waste residue separation and collection, realizing stable and high efficiency recycling of titanium tetrachloride from the titanium containing slurry, and avoiding enrichment of impuritiesin the slurry in subsequent dust collecting condensation system at the same time. Flexible selection of a recycling back to the dust collecting chamber mode or an intermittent type recycling to the dust collecting chamber mode is realized, flexible matching with the temperature in the dust collecting chamber is realized through controlling on slurry spraying flow amount, so that titanium tetrachloride recycling rate and efficiency can be increased effectively.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

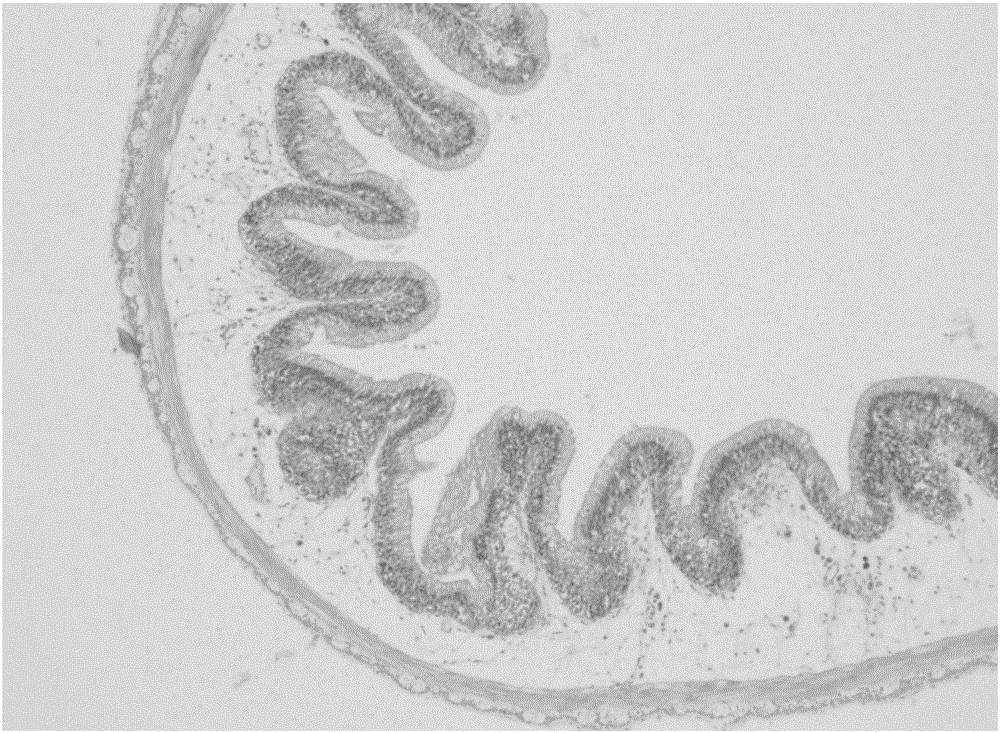

Compound feed for improving intestinal health of silurus meridionalis and preparation method thereof

InactiveCN106387506AWide variety of sourcesLow priceClimate change adaptationAnimal feeding stuffMedicineSilurus meridionalis

The present invention provides a compound feed for improving intestinal health of silurus meridionalis. Every 1,000 parts by weight of the compound feed contains Chinese herbal medicinal extract extracted by the following Chinese herbal medicines in parts by weight: 0.1-1.5 parts of dandelions, 0.15-2 parts of radix astragali, 0.1-1.5 parts of herba leonuri, 0.1-1.5 parts of haws, 0.1-1 part of penthorum chinense and 0.05-1.5 parts of basil seeds. The compound feed can improve the intestinal health of the silurus meridionalis. At the same time, the present invention also provides the compound feed prepared by a preparation method. The present invention relates to the technical field of aquatic feeds.

Owner:TONGWEI

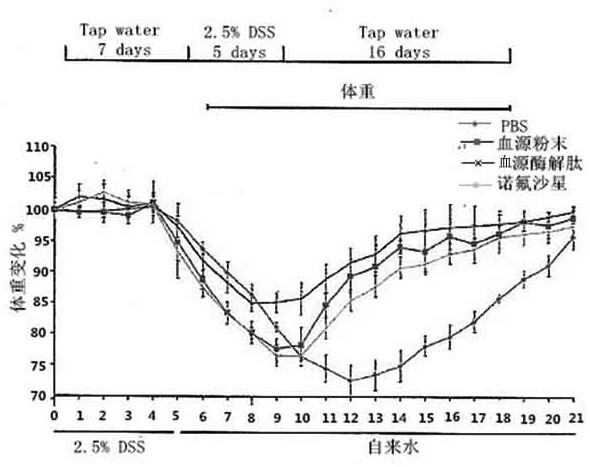

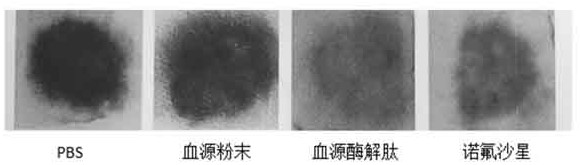

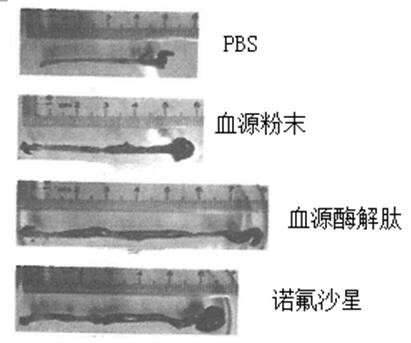

Application of a blood-derived enzymatic peptide in the preparation of drugs for inhibiting intestinal inflammation in animals

ActiveCN107929711BEasy to useIncreased drug resistanceHydrolysed protein ingredientsAntipyreticUltrafiltrationIntestinal inflammation

The invention provides an application of a blood-derived enzymatic hydrolysis peptide in the preparation of a drug for inhibiting intestinal inflammation in animals. Specifically, pig blood is used as a raw material and purified through grinding, enzymolysis, suction filtration, centrifugation, ultrafiltration and other processes to obtain A biologically active peptide that has the effect of inhibiting intestinal inflammation in animals. The dried active peptide is in the form of thin layer, powder, powder with lighter color. The biologically active peptide has the effect of inhibiting intestinal inflammation judged by its inhibitory effect on mouse intestinal inflammation, and can be used as feed, feed additive, pharmaceutical auxiliary material, etc. The blood-derived enzymatic peptide for inhibiting intestinal inflammation of the present invention is non-toxic and has no side effects, does not remain in animals, and has significant economic and social contributions. The invention will promote the rapid development of active peptide biological products in the pharmaceutical industry and the feed industry.

Owner:福建蓝昊肽生物科技发展有限公司

A peptide-based osteoblast targeting carrier and its preparation and application

InactiveCN106039316BLittle side effectsImprove targetingPowder deliverySkeletal disorderSide effectOsteoblast

The invention relates to an osteoblast targeted vector constructed based on a polypeptide. The targeted vector comprises a target head and a support. The target head is the polypeptide. The grafting mass ratio of the target head is 5-10%, and the mole grafting ratio is 2-6%. The targeted vector is prepared by subjecting the polypeptide and a vector to carboxylic acid covalent linking through polyethylene glycol, and is used for filling medicines treating bone fractures, osteoporosis, osteoarthritis, rheumatoid arthritis or tumor bone metastasis. Compared with the prior art, the targeted vector has osteoblast targeting performance, high bone tissue affinity and efficient medicine delivery capability, and is capable of enhancing osteogenesis effects, reducing medicine using amounts, and reducing cell toxicity and side effects. The targeted vector provides an important medicine delivery tool for future osteoporosis treatment.

Owner:TONGJI UNIV

Fuel cell stack

ActiveCN100429819CSimple and flexible structureIncrease volumetric power densityFuel cells groupingCell electrodesFuel cellsEngineering

The fuel cell pile includes end plate, current conduction board, multiple pole plates, multiple membrane electrodes, and seal washers. There is center hole on end plate, current conduction board, pole plates, and membrane electrodes respectively. There is connection orifice on end plate, and there is penetration hole on pole plate corresponding to the connection orifice. Current conduction board and membrane electrodes include holes corresponding to the said orifices and the penetration holes. Seal washers are arranged around the penetration holes on one face of pole plate as well as around center hole, and outer circumference on the other face. Bolts are separated from fuel channels in the invention. Reacting masses of cathode and anode can be diffused to any parts of cathode and anode. Thus, resultant of reaction and nonreactant can be eliminated in time. Advantages are: simple structure, wide adaptability, suitable to different devices by changing size and shape of fuel cell.

Owner:BYD CO LTD

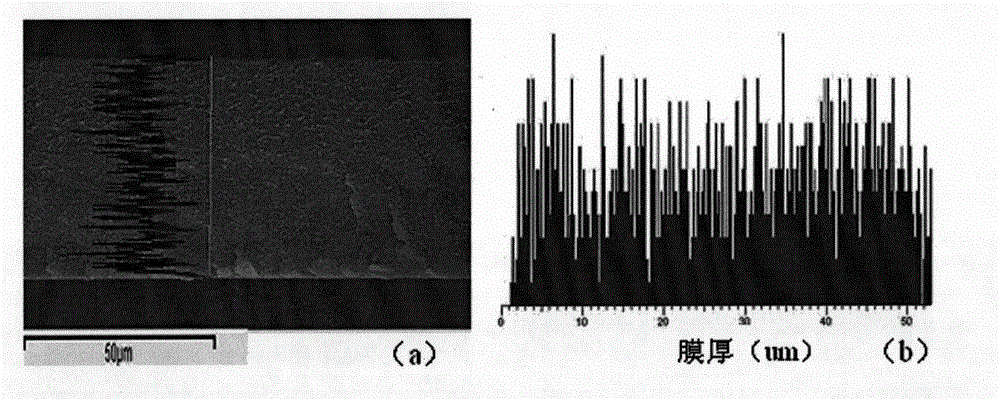

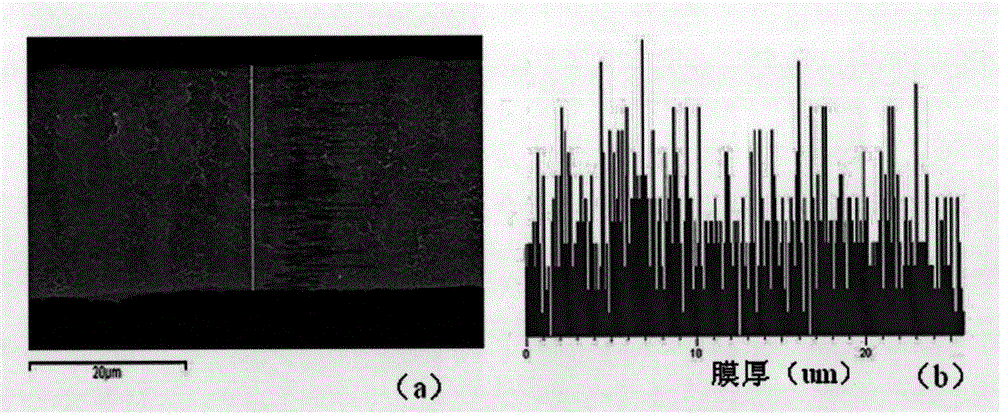

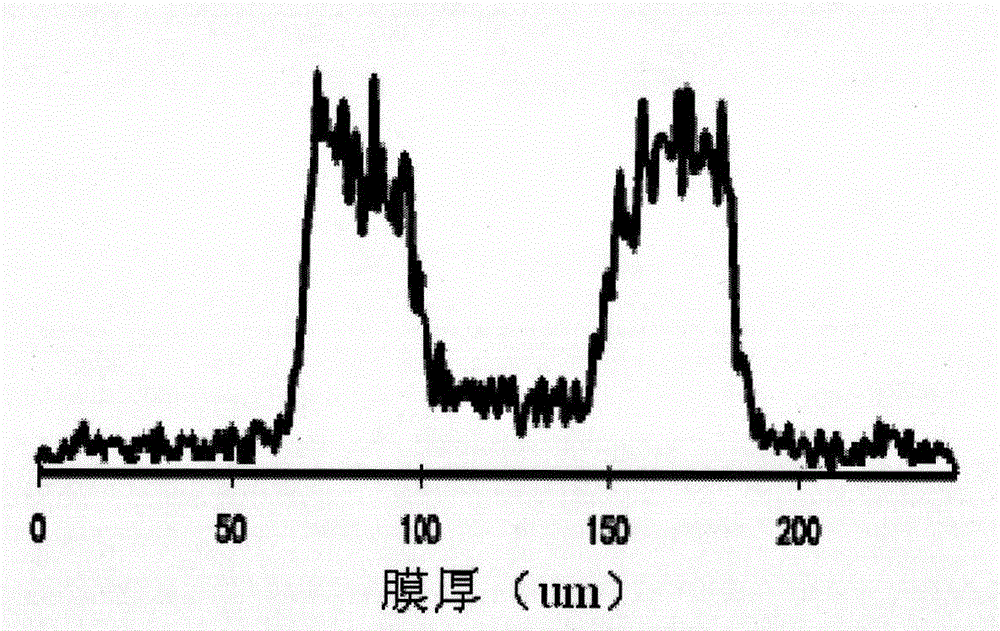

Proton exchange membrane and preparation method thereof

InactiveCN101898091BEvenly distributedWill not enrichSemi-permeable membranesProtonFluorine containing

The invention discloses a method for preparing a proton exchange membrane, which is characterized by comprising the following steps of: pre-irradiating fluorine-containing olefin polymer powder and performing graft polymerization with a styrene monomer to prepare a membrane; and sulfonating the membrane to obtain the proton exchange membrane. The invention also discloses a proton exchange membrane prepared from the preparation method. The proton exchange membrane has the advantages of uniformly distributed monomers and high dimension stability of the membrane. The method for preparing the proton exchange membrane has the advantages of simple steps, low cost and suitability for industrial preparation of large-area continuous-roll proton exchange membranes.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

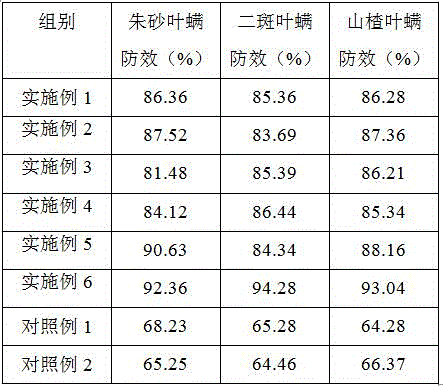

Compound acaricide for greening plants and preparation method of compound acaricide

InactiveCN106508984AChange internal structurePromote hydrolysisBiocideDead animal preservationEcological environmentBULK ACTIVE INGREDIENT

The invention relates to the technical field of acaricide compounding and discloses a compound acaricide for greening plants and a preparation method of the compound acaricide. The acaricide is mainly prepared from active ingredients as follows: aconite, radix salviae miltiorrhizae, artemisia argyi, flos lonicerae, rhizoma chuanxiong, bauhinia variegate, radix stellerae chamaejasmes, photinia serratifolia, rhizoma dryopteridis crassirhizomatis, an organic solvent, a penetrant, a lubricant and and water. The preparation method of the compound acaricide comprises main steps of cleaning, decoction, concentration and the like. Compared with a traditional compound acaricide, the acaricide has the following characteristics: 1, common green plant Chinese herbal medicines are taken as main raw materials and are not prone to accumulating on plants and are safe and friendly to the ecological environment; 2, the preparation method is simple and feasible, low in cost and suitable for large-scale popularization in urban greening projects; 3, the raw materials are unique in mixing action mechanism and can play a synergistic efficiency to improve the control rate of pest mites, in particular to tetranychus cinnabarinus, tetranychus urticae, tetranychus viennensis zacher and other common pest mites of green plants.

Owner:南宁马瑞娜装饰工程有限公司

A mixed surfactant for controlling particle size of fluoropolymer emulsion and method for preparing fluoropolymer

The invention discloses a mixed surfactant for controlling the particle size of a fluorine-containing polymer emulsion and a method of preparing a fluorine-containing polymer therewith. The mixed surfactant is composed of any two or three selected from perfluoropolyether carboxylic acid, perfluoro fatty acid and low-molecular-weight perfluoropolyether. By using the mixed surfactant in water-phase polymerization of the fluorine-containing polymer, the particle size of the fluorine-containing polymer emulsion is controlled to be 50-150 nm and solid content of the emulsion is controlled to be 25-35. In addition, a reaction solution for preparing the fluorine-containing polymer with the mixed surfactant is homogeneous-phase, so that pre-emulsion before polymerization is unnecessary. The mixed surfactant can be applied in a fluorinated monomer emulsion polymerization reaction instead of perfluoroctanoic acid, thereby avoiding the problems of environment pollution, biotoxicity and the like due to usage of the perfluoroctanoic acid.

Owner:ZHEJIANG XINGTENG CHEM

Compound preparation for dissolving staphyloase and preparation method

InactiveCN100450546CLower resistanceUnique bactericidal mechanismAntibacterial agentsPeptide/protein ingredientsSide effectMonilinia laxa

The present invention discloses a lysostaphin compounded preparation. Said preparation comprises bacteria-killing effective quantity of lysostaphin and lysozyme. Said lysostaphin compounded preparation has higher bacteria-killing effect as compared with single lysostaphin, not only has the strong bacteria-killing action for Gram-positive bacterium and Gram-negative bacterium, but also has the good effect for killing the fungi of Candida albicans and red trichophyton, etc. It has high bacteria-killing activity and stability, does not produce drug resistance, and has no toxic side effect.

Owner:SHANGHAI HI TECH BIOENG

A kind of wind power blade and its manufacturing method

ActiveCN109203515BResin content controllableNo quality riskFinal product manufactureMachines/enginesGlass fiberTurbine blade

The invention discloses a wind turbine blade, which comprises a pressure surface shell and a suction surface shell of a girder web preform. The girder web preform comprises a girder die, a core material, girder UD fabrics, upper surface glass fiber cloth, and a web. The core material, girder UD fabrics, upper surface glass fiber cloth, and web are paved on the girder die in sequence. The manufacturing method comprises following steps: paving a guide net, demoulding cloth, the core material, girder UD fabrics, and upper surface glass fiber cloth on the girder die; then placing the web; carryingout curing and moulding to obtain the girder web preform; paving the girder web preform and other materials on a suction surface shell die and a pressure surface shell die, then carrying out curing and moulding to obtain the suction surface shell and the pressure surface shell; and adhering the suction surface shell and the pressure surface shell together to obtain the wind turbine blade. Beforethe girder web preform is manufactured, the web is produced by a VARTM technology; then the web is paved on the girder to produce the girder web preform, the resin content is controllable, and the produced wind turbine blade does not have quality risk of the web.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Preparation method for FDY ultra-fine nylon fibers

The invention relates to the field of spinning industry and in particular relates to a preparation method for FDY ultra-fine nylon fibers. The method comprises the following steps: when nylon is heated for melting and then is sprayed out by a filament outlet of a spinning assembly of a spinning device, the filament outlet of the spinning assembly of the spinning device is within 10cm, and the temperature is controlled to be 200-250 DEG C, so that the filament bundle is cooled uniformly. According to the method, the temperature of the filament outlet of the spinning assembly of the spinning device is controlled to be 200-250 DEG C, so that heat cannot be enriched, the temperature control range is exceeded, the prepared FDY ultra-fine nylon fibers are relatively highly elastic, and prepared products have the clear textures and can be widely applied to weaving fabrics of underwear and elasticity-reinforced silk stockings.

Owner:FUJIAN JINGFENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com