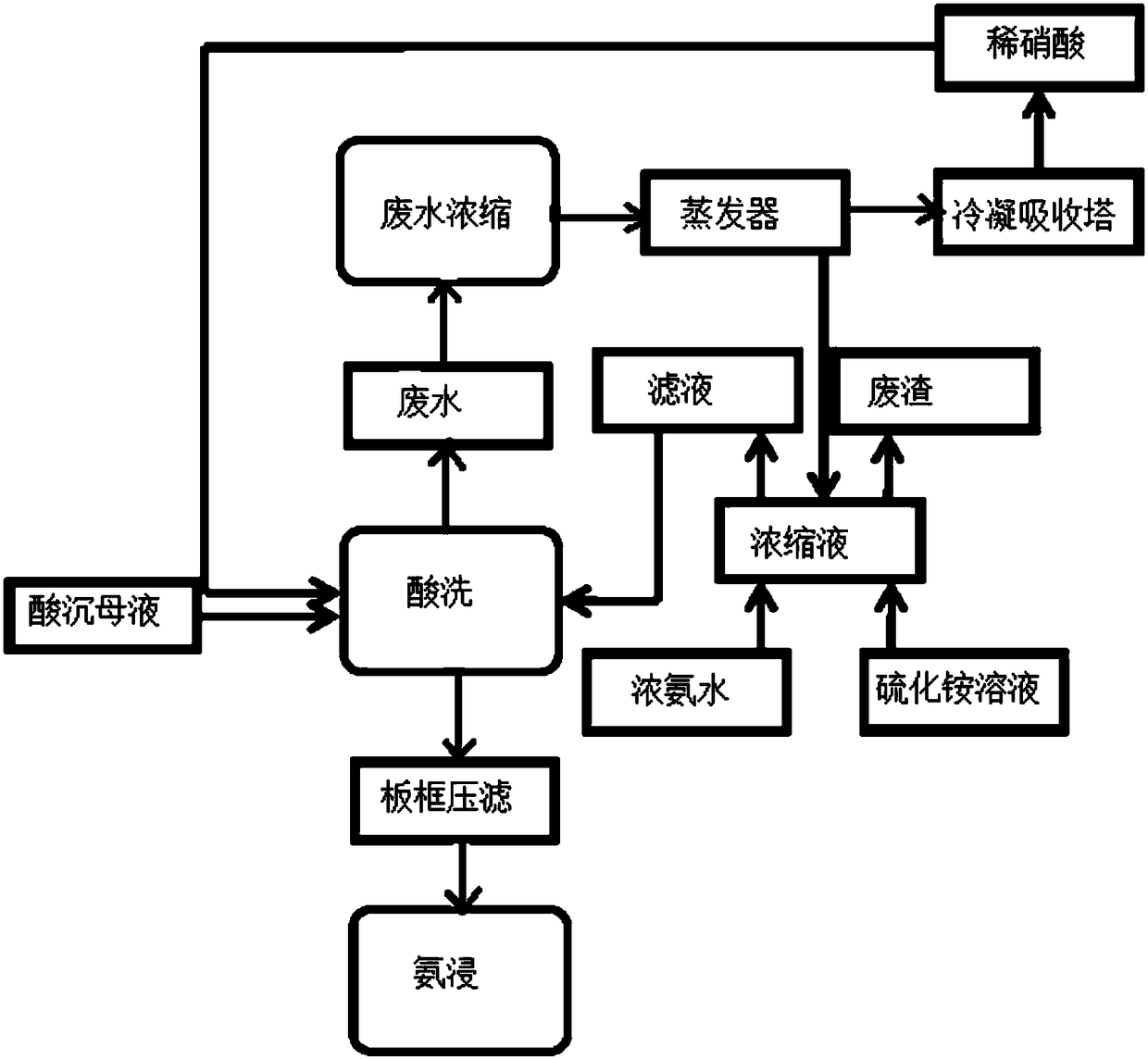

Production process for treating ammonia-nitrogen wastewater

A production process and ammonia nitrogen wastewater technology, which is applied in filtration treatment, water/sewage treatment, frozen water/sewage treatment, etc., can solve the problems of poor conversion rate of water washing process, and achieve the effect of low cost, simple operation and strong feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Add 2000ml of pure water into a 2500ml three-neck flask, add 400g of industrial molybdenum oxide in proportion, and add 35ml of nitric acid for acidification, use steam to heat and keep warm for one hour, and discharge the material after the reaction is completed. The filter cake contains about 30% of water, and the calculated filter cake contains 171ml of water. This process produces 1830ml of waste water. Use a three-necked flask to concentrate and evaporate this part of the waste water. The acid mist formed by evaporation is collected by a condenser until it evaporates to the original One-tenth of the liquid, 1230ml of dilute nitric acid was collected after the experiment. After cooling, nitrate crystals appeared. After filtration, 130ml of concentrated ammonia water was added to adjust the pH value to 4, and then ammonium sulfide was added for heat preservation reaction for 0.5 hours, and the solution formed a paste. After cooling, utilize suction filtration facility...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com