Titanium containing slurry titanium tetrachloride recycling system and recycling method

A technology of titanium tetrachloride and recovery system, applied in the direction of titanium tetrachloride, titanium halide, energy input, etc., can solve the problems of high production energy consumption, large environmental pollution, low production efficiency, etc., to improve the recovery rate and recovery The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

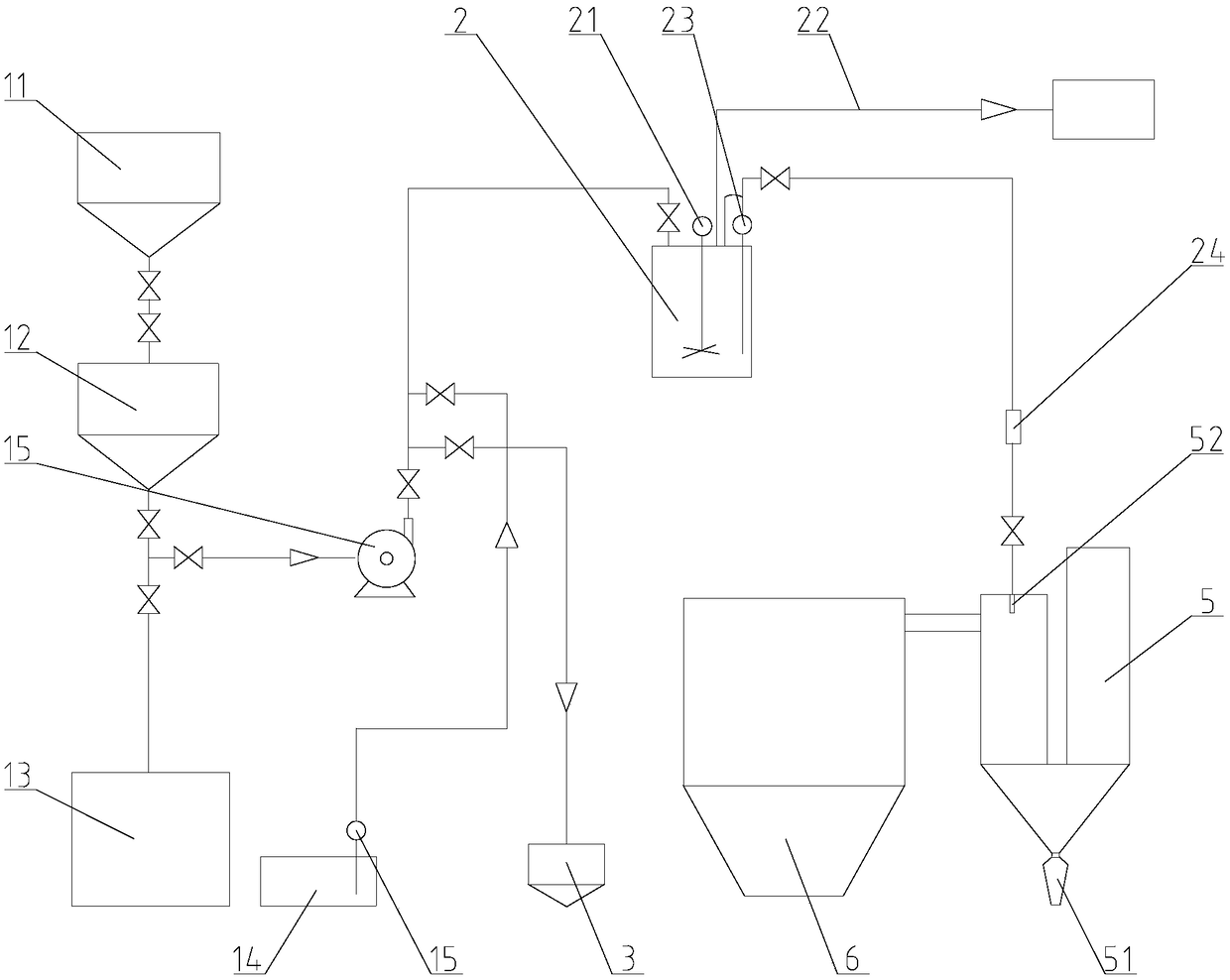

Method used

Image

Examples

Embodiment 1

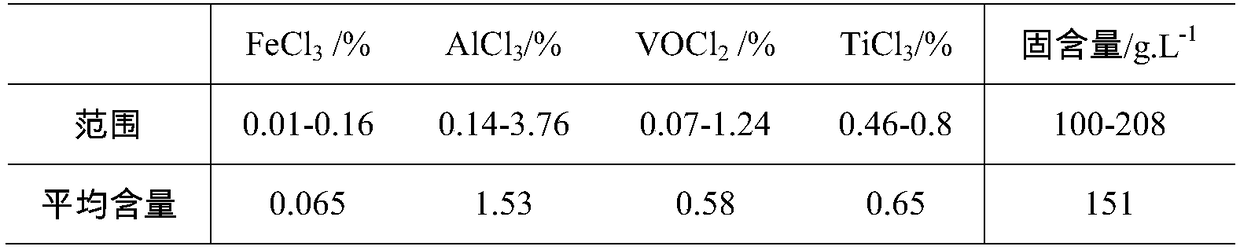

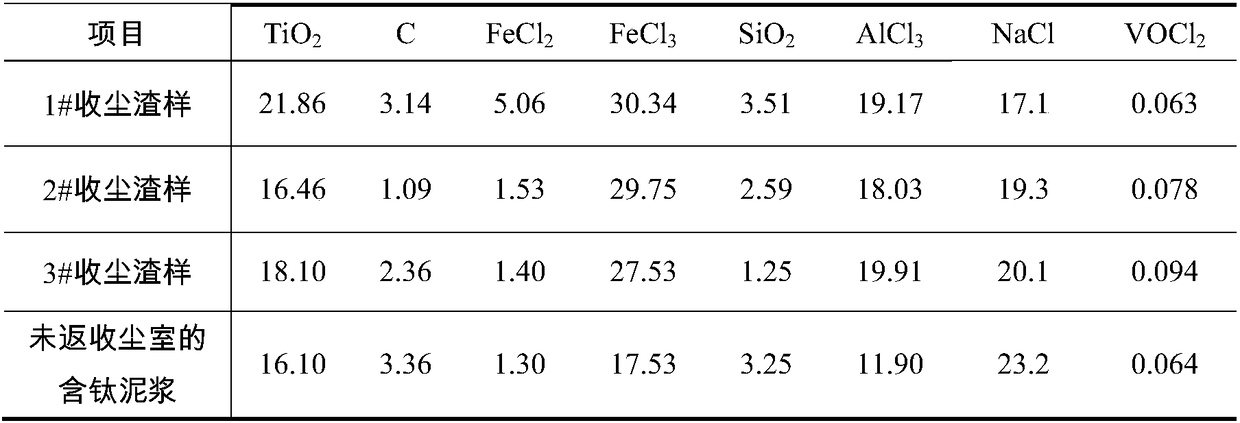

[0022]Using the titanium-containing mud with a solid content greater than 100g / L produced by the titanium tetrachloride refining process as raw material, carry out the recovery of titanium tetrachloride by using the titanium tetrachloride recovery system for titanium-containing mud described in the present invention for 48 hours. Test, the main composition of titanium-containing mud is TiCl 4 , the remaining impurities are FeCl 3 , AlCl 3 、VOCl 2 、TiCl 3 , the solid content of impurities is 100-208g / L, the inlet temperature of the dust collection room is controlled between 385 and 400°C, the spray flow rate of titanium-containing mud is 0.8t / h when returning to the dust collection room, and the outlet temperature of the dust collection room Control between 330 ~ 345 ℃. The composition of impurities in the titanium-containing mud raw material is shown in Table 1:

[0023] The impurity composition of the titanium-containing mud used in Table 1 Example 1

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com