Process method of micro-powder battery grade lithium hydroxide monohydrate

A technology of lithium hydroxide monohydrate and process methods, applied in chemical instruments and methods, lithium oxides;/hydroxides, inorganic chemistry, etc., can solve the problems of high product impurities, easy fluctuations in quality, and high preparation costs, and achieve The effect of stable product quality, improved product quality and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

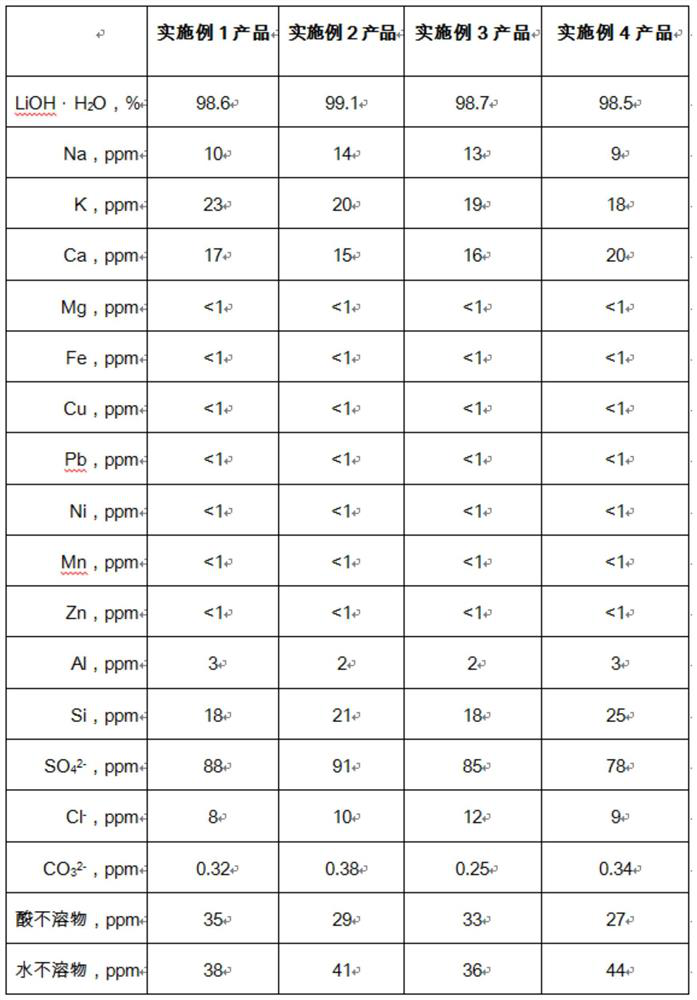

Examples

Embodiment 1

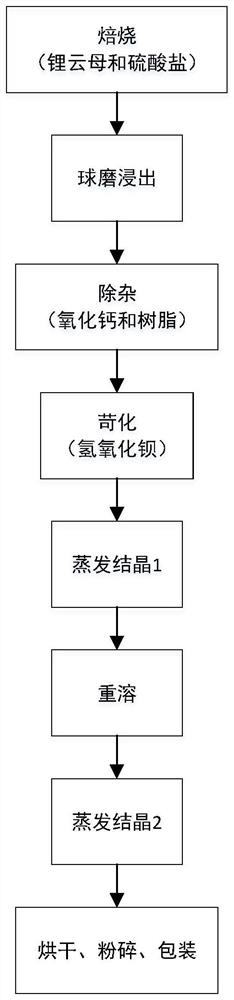

[0037] like figure 1 A process method for micropowder battery grade lithium hydroxide monohydrate, comprising the following steps:

[0038] In step S1, the lepidolite and sulfate are in a ratio of 1.3-2.5:1 by mass, at a temperature of 800-1200 degrees, and calcined for 0.5-2 hours, and then cooled to room temperature to obtain calcined clinker;

[0039] Step S2, ball milling and leaching the roasted clinker and water in a ratio of 2 to 0.5:1 to obtain a slurry of lithium sulfate solution;

[0040] In step S3, the slurry of the lithium sulfate solution obtained in step S2 is subjected to liquid-solid separation to obtain a lithium sulfate solution and lithium-containing silica sand; its subsidiary product, silica sand, can be directly sold;

[0041] In step S4, the obtained lithium sulfate solution is added with calcium oxide or sodium hydroxide to adjust the pH value to 11-13, and liquid-solid separation is performed to obtain a lithium sulfate purification solution;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com