Combined supporting construction method of two rows of grouting piles and pull anchoring and shotcreting layer

A technology of anchoring, spraying and joint support, which is applied in the direction of excavation, sheet pile wall, foundation structure engineering, etc., can solve the problems of poor slope stability and large foundation pit excavation depth, so as to improve efficiency, protect the environment, The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

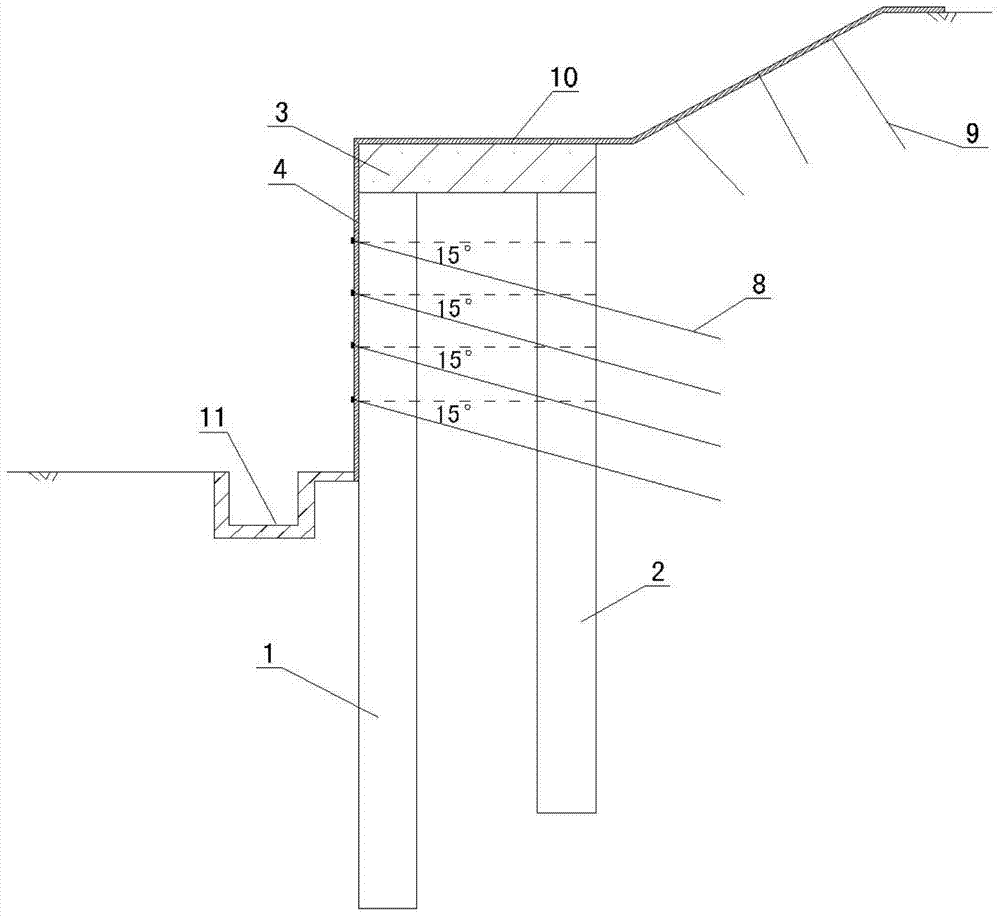

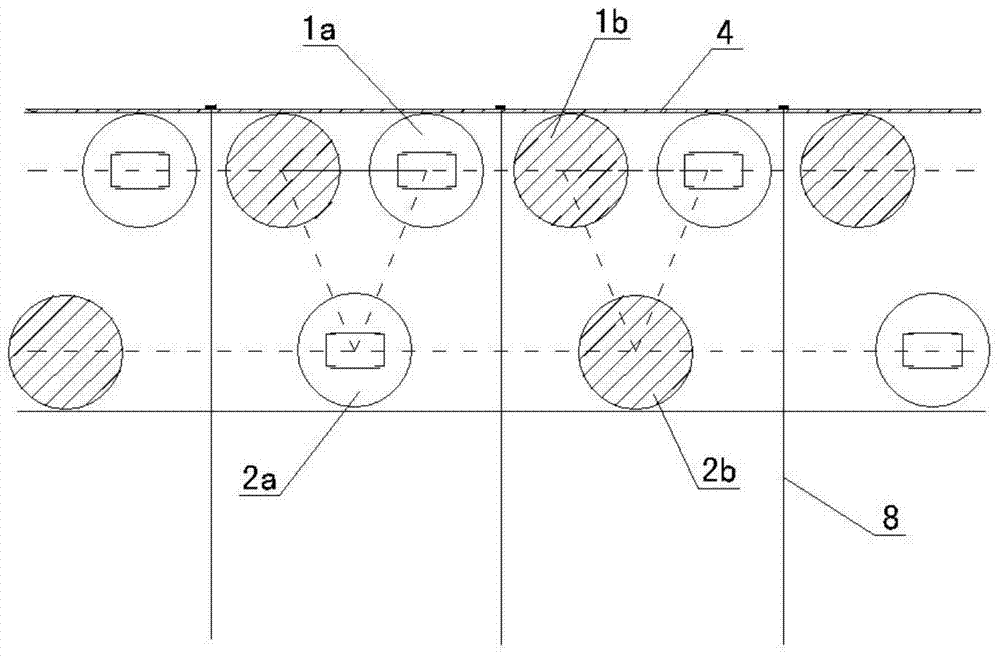

[0034] see figure 1 , figure 2 , image 3 and Figure 4 , the combined support structure of the double-row grouted piles and the tension-anchor-sprayed layer in this embodiment is

[0035] A double row of grouting piles consisting of a front row of piles 1 and a rear row of piles 2 is set up. The front row of piles 1 and the rear row of piles 2 are respectively arranged at equal intervals by reinforced crushed stone grouting piles and plain piles. The rear row of piles 2 are jointly connected by the top ring beam 3; the anchor-spraying layer 4 is formed on the excavation support surface; Stone grouting pile 2a is to be in the position of left and right staggered.

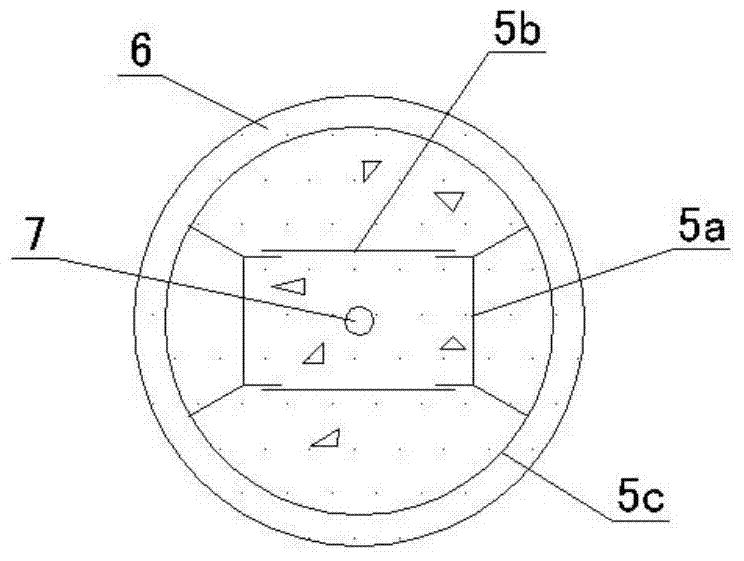

[0036] The pile core of the reinforced crushed stone grouting pile is a reinforced steel unit, and the pile body is formed by mixing crushed stone and cement slurry under high pressure. The plain pile 1b in the front row and the plain pile 2b in the back row are plain concrete piles.

[0037] Such as image 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pile diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com